RTM (resin transfer molding) mold

A technology of mold and negative mold, which is applied in the field of forming composite FRP products, can solve problems such as difficulty in guaranteeing product quality, surface resin deposition, and insufficient product strength, and achieve the effects of improving the main body strength of the product, low cost, and eliminating resin deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

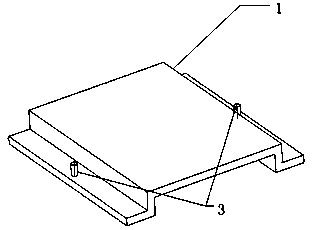

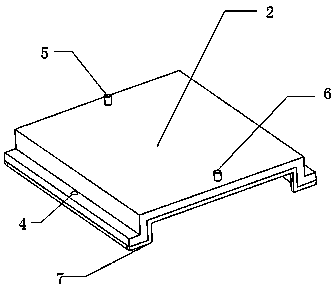

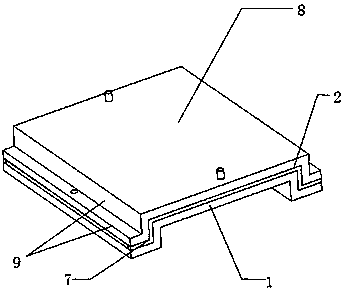

[0016] The technical solution of the present invention is a kind of RTM mould, comprises positive mold 1 and negative mold 2, as Figure 1-3 As shown, the male mold 1 is based on glass fiber reinforced plastic, and the female mold 2 is divided into a female mold body 8 and an edge 9. The edge 9 is arranged at both ends of the female mold body 8 and is symmetrical to the female mold body 8. The female mold body 8 is formed by Silica gel is the substrate, and the edge 9 is based on glass fiber reinforced plastics; the middle position of the two ends of the male mold 1 is provided with a positioning pin 3, which has a positioning function, and a positioning hole is provided on the edge 9 of the female mold 2 corresponding to the male mold 1 4. A sealing strip 7 is provided at the junction between the edge of the female mold 2 and the male mold 1. The sealing strip 7 is compressible, and the sealing strip 7 seals the cavity at the junction between the male mold 1 and the edge 9 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com