Axle chain

A shaft chain and chain plate technology, which is applied in the field of shaft chains, can solve problems such as increased interference and wear, unstable meshing and transmission of chain sprockets, and inconvenient disassembly, and achieves anti-rotation positioning, reasonable axial fixation, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

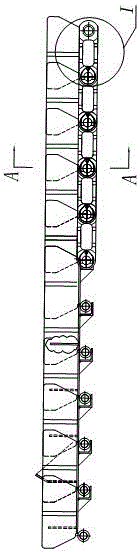

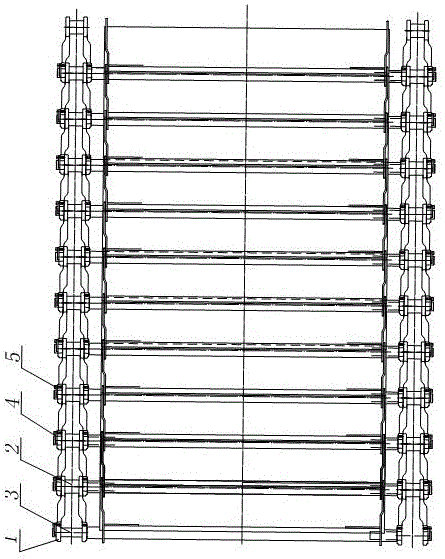

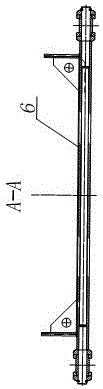

[0026] The specific implementation method is in Figure 1 to Figure 5 Among them, the axis chain of the present invention includes a chain plate 1 with inner and outer connecting end holes, a square-circle convex sleeve 2 installed into the inner connecting end hole of the chain plate, inserted into the outer connecting end hole of one link plate and the other The mandrel 3 in the square-circle convex sleeve at the inner connection end of the chain plate is close to the outer connection end of the chain plate and inserted into the splint 4 in the groove of the mandrel, and the screw 5 that fastens the splint to the outer connection end of the chain plate, The conveying body 6 installed in the middle of the mandrel; said chain plate, its inner connection end is provided with oblate hole, and the outer connection end is provided with round hole.

[0027] exist Figure 5 Among them, the inner connection end a of one chain plate, the outer connection end b of the other chain plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com