Penetrating rod for carburizing, quenching and mounting of ring-shaped parts

A technology for carburizing and quenching and annular parts, which is applied to the field of carburizing and quenching of annular parts for inserting and piercing rods, can solve the problems of inconvenient loading, unloading and hoisting process, affecting the quality of parts, affecting production efficiency, etc., to ensure the effect of carburizing and quenching, prolong the The effect of service life, carding and hoisting convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

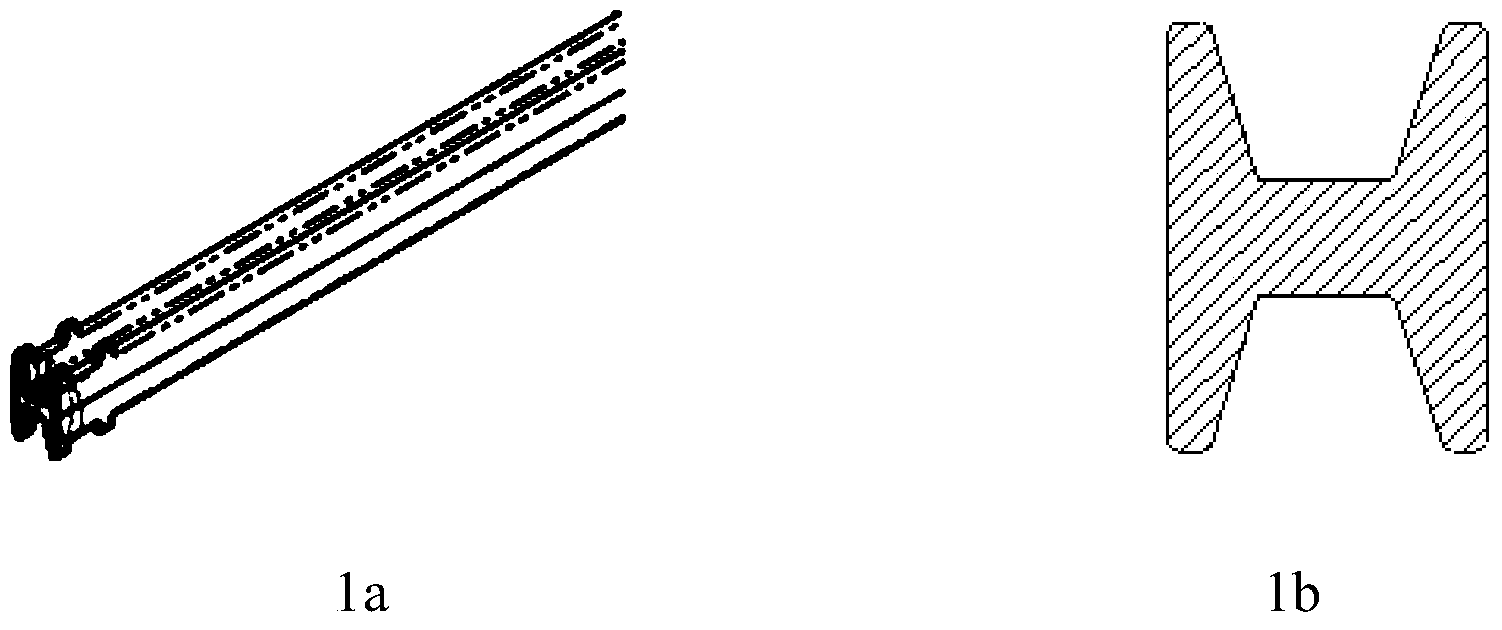

[0021] refer to image 3 , the present invention is a carburized and quenched ring-shaped part with a snap-through rod, such as image 3 As shown in a, it includes a rod body 1, and a chuck 2 and a support head 3 that are integrally arranged at both ends of the rod body 1; image 3 As shown in b, the upper and lower end surfaces of the rod body 1 are respectively outwardly protruding cylindrical surfaces, and the end surfaces on both sides are arranged in planes.

[0022] In this preferred embodiment, if image 3 As shown in b, the upper and lower end surfaces of the rod body 1 are arranged symmetrically, and the end surfaces on both sides are parallel and vertically arranged. Among them, the radius of the cross section of the rod body 1 corresponding to the arc is 30-40mm; the distance be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com