Tufted carpet machine capable of rotating along circumference

A tufted carpet and circumference technology, applied in the field of processing equipment for textile products, can solve problems such as unsightly and achieve the effect of meeting the requirements of pattern quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below, the structure and working principle of the present invention will be further described in conjunction with the accompanying drawings.

[0017] The tufted carpet machine capable of circular rotation of the present invention is used to realize the processing of tufted carpets, especially the processing of tufted carpets with curved outline patterns (such as flowers, leaves, etc.). Such as Figure 4 As shown, it is a physical photo of the tufted carpet processed by the tufted carpet machine of the present invention, wherein the black one is the tufted carpet pattern formed by processing, which is located on the stretcher.

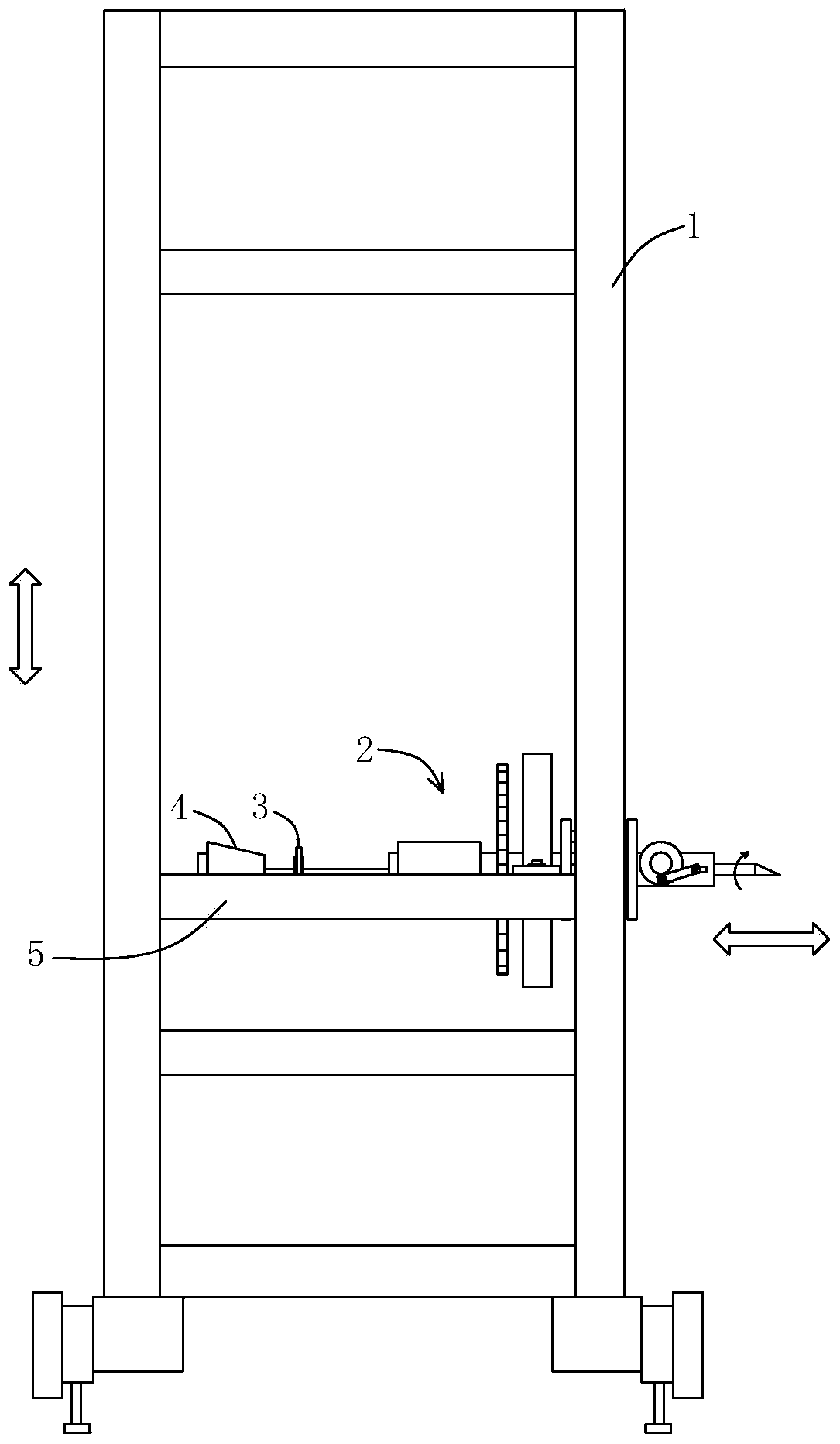

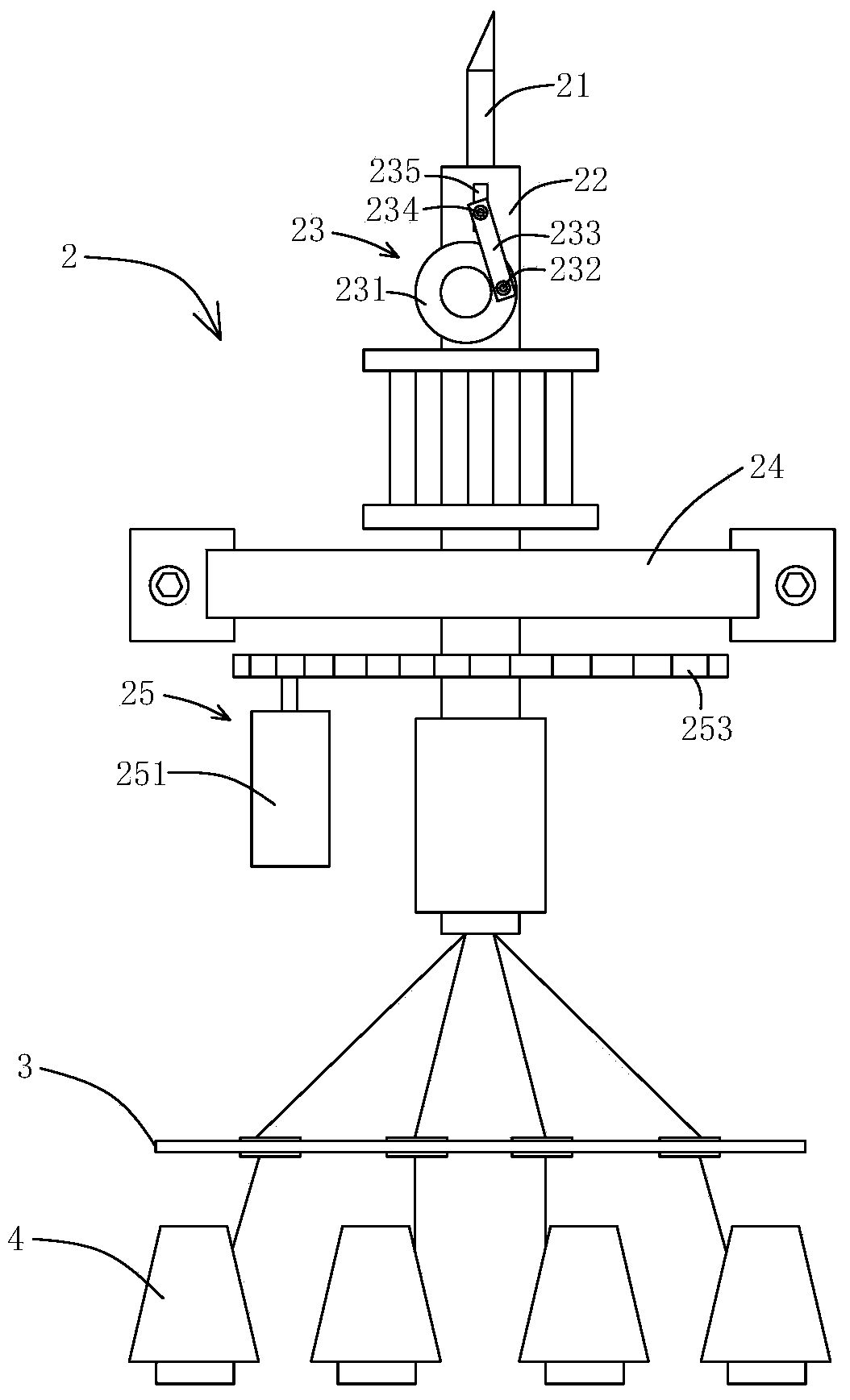

[0018] see figure 1 , the tufted carpet machine that can be used for circular rotation of the present invention includes a frame 1, a lifting drive device (not shown in the figure), a tufting bolt 2 and a wire wheel 4 for supplying the tufting bolt 2. The driving device can realize the reciprocating movement of the tufting bolt 2 along the heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com