TBM experiment table thrust hydraulic system capable of conforming sudden-change load

A technology for hydraulic systems and test benches, which is applied in the direction of fluid pressure actuators, servo motors, and mechanical equipment. It can solve the problems of not being able to adapt to sudden loads and large eccentric loads, and achieve the purpose of buffering pressure shocks and prolonging service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

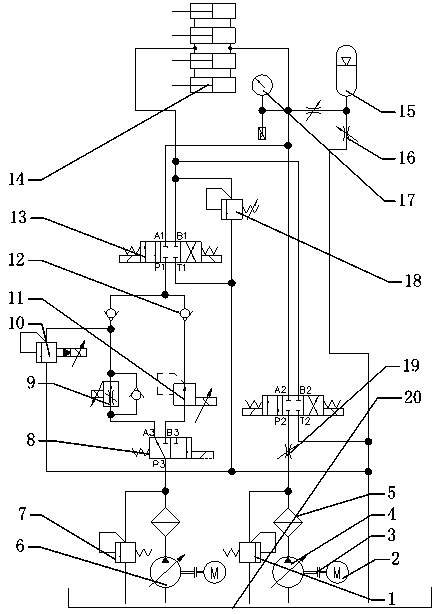

[0018] Attached below figure 1 And embodiment further illustrate the present invention.

[0019] Such as figure 1 Shown, the present invention comprises high and low pressure oil source, high and low pressure control oil circuit and propulsion hydraulic cylinder inlet and outlet oil circuit; Wherein:

[0020] High-pressure control oil circuit, including: two-position three-way reversing valve 8, proportional pressure reducing valve 11, proportional one-way throttle valve 9, proportional overflow valve 10, first one-way valve 12, second one-way valve 12 and The first three-position four-way reversing valve 13; the A3 port of the two-position three-way reversing valve 8 is divided into two routes after the proportional one-way throttle valve 9, and one way passes through the first one-way valve 12 and the first three-way reversing valve. The P1 port of the one-position four-way reversing valve 13 is connected, the other is connected to the oil tank 20 through the proportional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com