Modular shaft connecting structure

A modular, shaft-connected technology, used in couplings, rigid shaft couplings, textiles and papermaking, etc., can solve the problem of not being widely applicable, and achieve the effect of improving assembly capacity and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

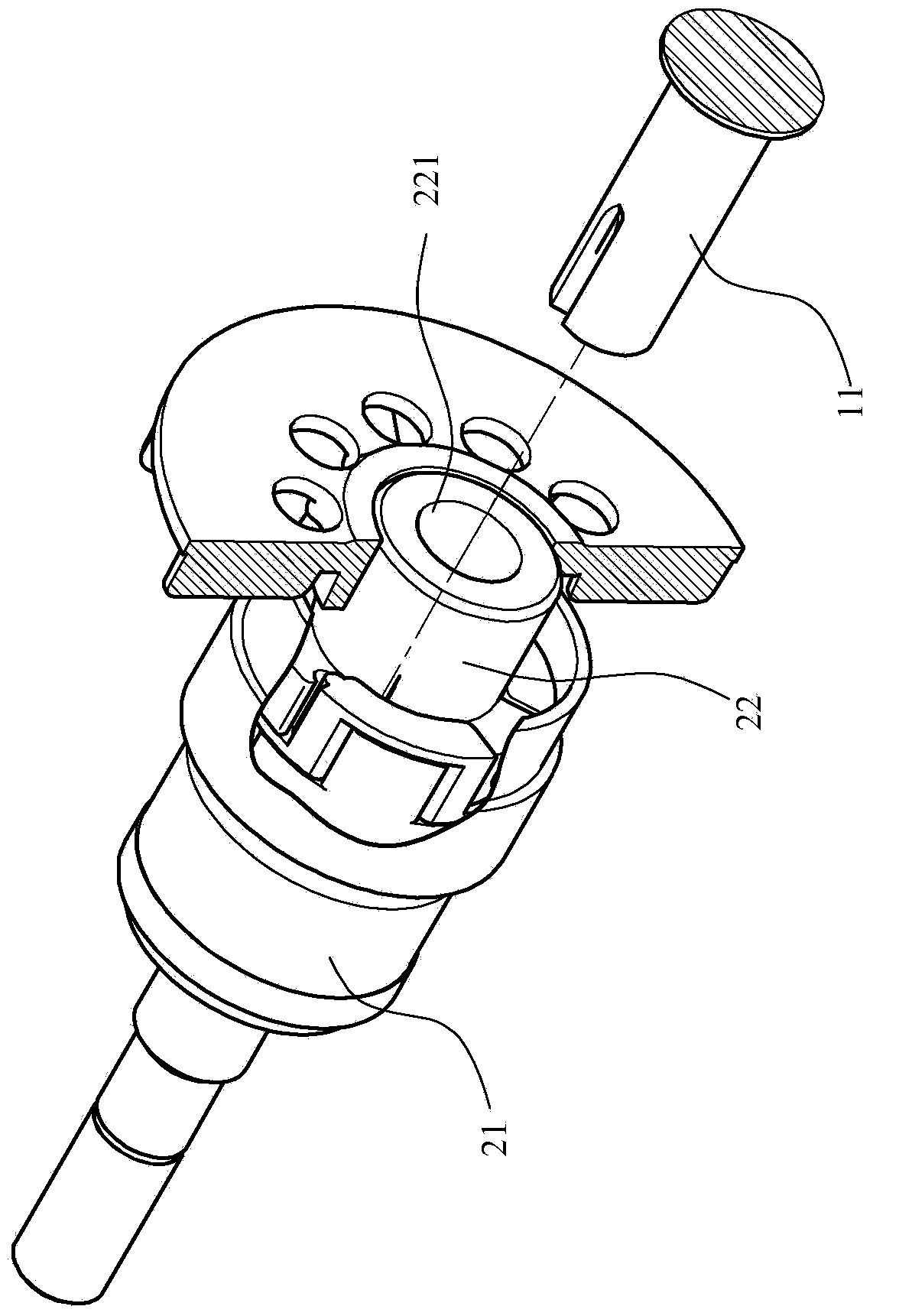

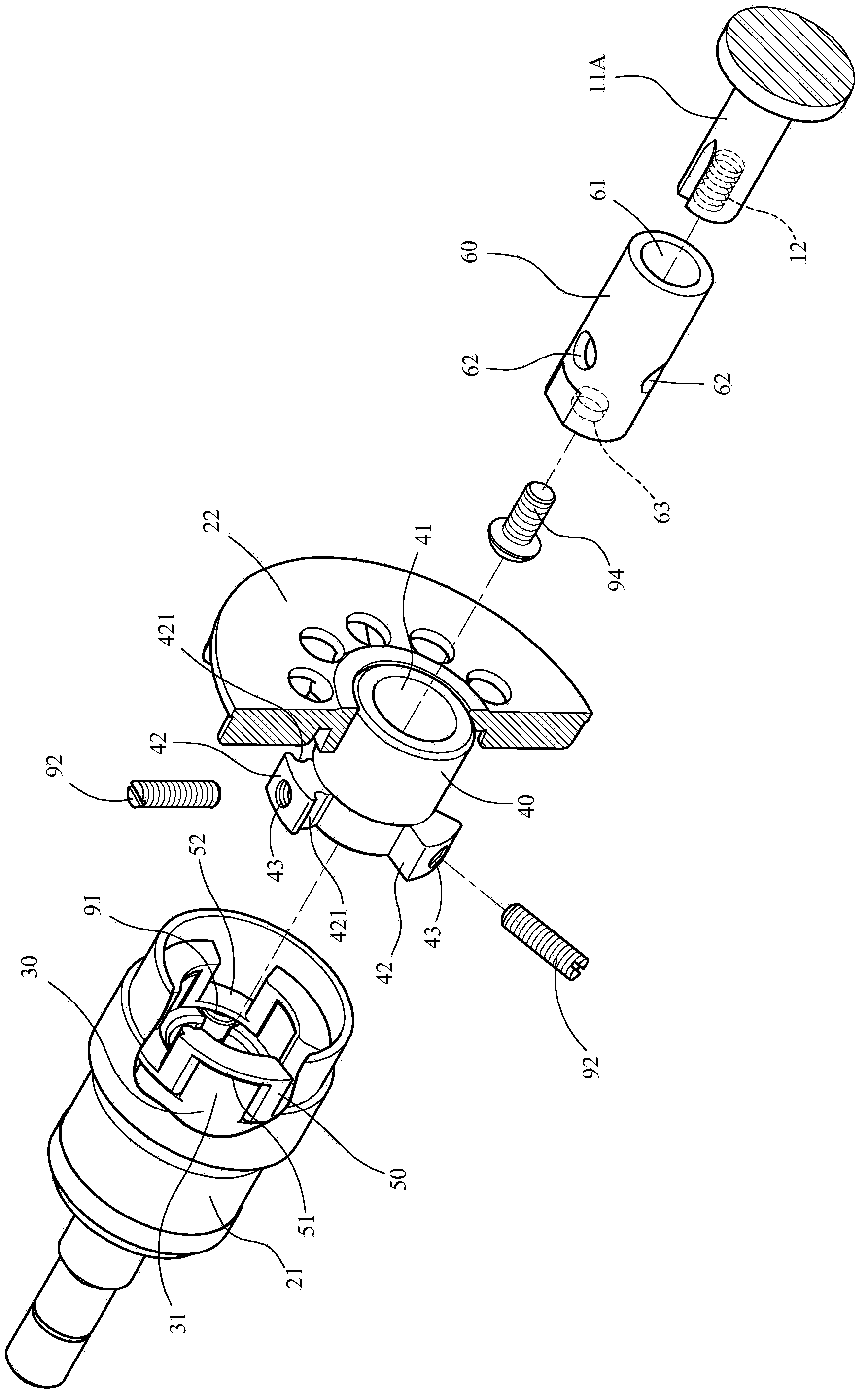

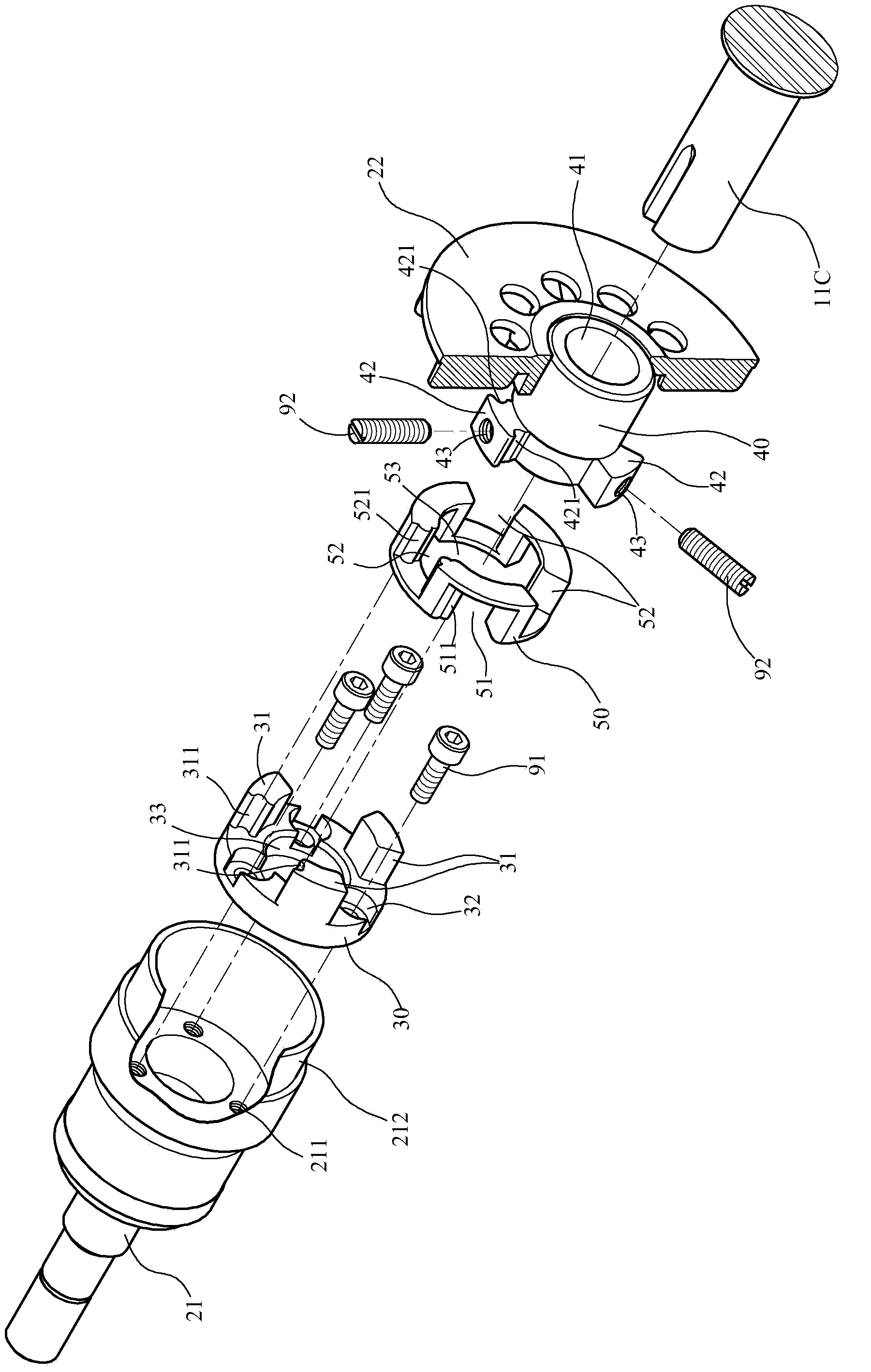

[0035] The present invention mainly provides a modular shaft connection structure that allows motors of the same size and format to be quickly installed and used for various sewing equipment, such as figure 2 The exploded view of the modular shaft connection structure structure of the first embodiment of the present invention, image 3 As shown in the structural exploded view of the first usage mode of the modular shaft connection structure of the present invention, the modular shaft connection structure of the present invention basically includes: a first shaft connection block 30, a second shaft connection block 40, a The connection block 50, and at least one shaft sleeve 60; wherein:

[0036] The first pivot block 30 is arranged on the shaft end of a motor rotating shaft 21, and a plurality of first claws 31 arranged at predetermined intervals protrude from the end surface; in this embodiment, the first pivot block 30 utilizes The screw 91 is locked on the shaft end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com