A large X-ray machine operating table arm support

A technology of an operating bed and an X-ray machine, applied in the field of bed arm rests, can solve problems such as inability to position at any point, and achieve the effects of simple structure, convenient installation and use, and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

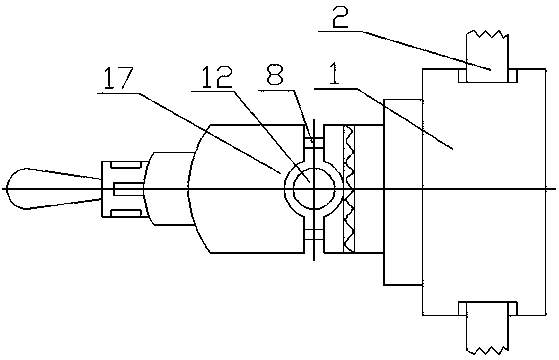

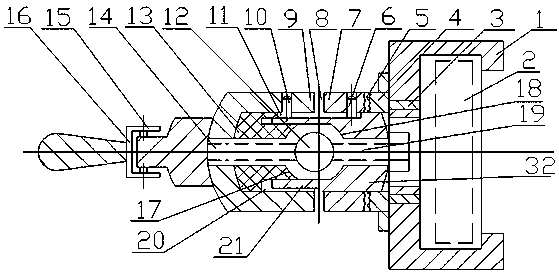

Embodiment 1

[0046] Embodiment 1, referring to the accompanying drawings, the sliding sleeve buckle opening (26) of the sliding sleeve (1) is sleeved on the rod of the side frame rod (2). The tail core bolt (19) is connected with the tail core bolt hole (25) of the sliding sleeve (1) and the tail core connecting screw hole (31) of the tail core (32). The adjusting head core screw (14) of the adjusting head (34) passes through the head cover connecting hole (29) of the head cover (9) and is connected with the head core connecting screw hole (30) of the head core (13). The outer diameter of the head core (13) and the tail core (32) are sleeved in the inner cavity (28) of the head cover (9) and the middle sleeve (7), and the tail core (32) is installed in the tail core installation port ( 36), and installed in the inner cavity (28) of the middle sleeve (7), the head sleeve bolt (10) is inserted into the adjustment groove (11) through the head sleeve bolt hole (27), and the middle sleeve bolt ...

Embodiment 2

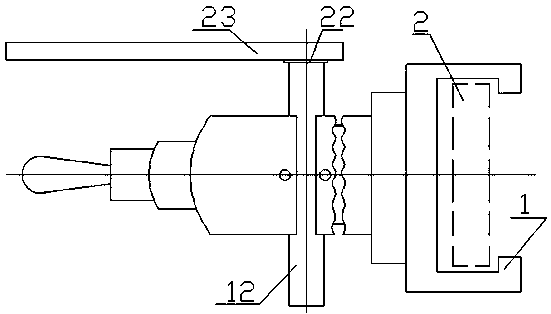

[0047] Example 2, referring to Example 1, referring to the accompanying drawings, the head core (13) and the tail core (32) do not need the transmission connecting groove (20) and the transmission connecting core strip (21), but the head core (13) and the tail core (32) are connected as a whole, and a circular hole is opened in the middle of the head core (13) and the tail core (32) to install the arm support guide rod (12). For other structures, refer to Embodiment 1, and the same effect can be achieved.

Embodiment 3

[0048] Example 3, referring to Example 1 or 2, referring to the accompanying drawings, remove the handle (16), head cover (9), middle cover (7), seat cover (4), head core (13), tail core ( 32) and related bolts, and the sliding sleeve (1) is transformed into a ratchet structure, that is, a ratchet structure is installed between the arm support (23) and the side frame rod (2). 23) When it is necessary to run and / or stay locked during use on the side of the operating bed, it can be run and locked with the distance of the stroke.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com