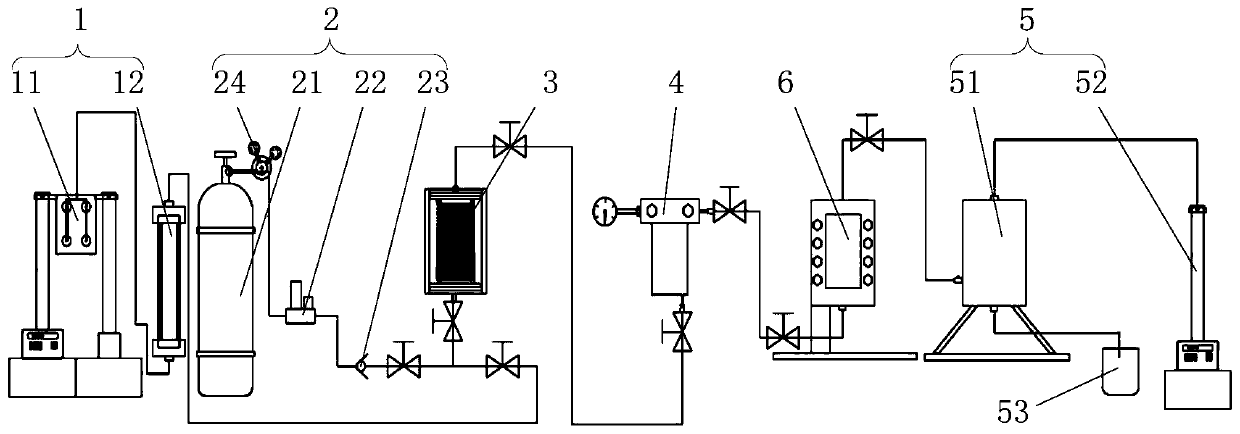

A high-temperature and high-pressure foam rheological testing system and experimental method

A high-temperature, high-pressure rheological and high-temperature, high-pressure technology, which is applied in the direction of direct current flow characteristics measurement, can solve problems such as opposite laws, huge differences in foam rheology, and large differences in rheological equation results, etc., to achieve rapid installation and use, and accurate testing High performance, simple and fast process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

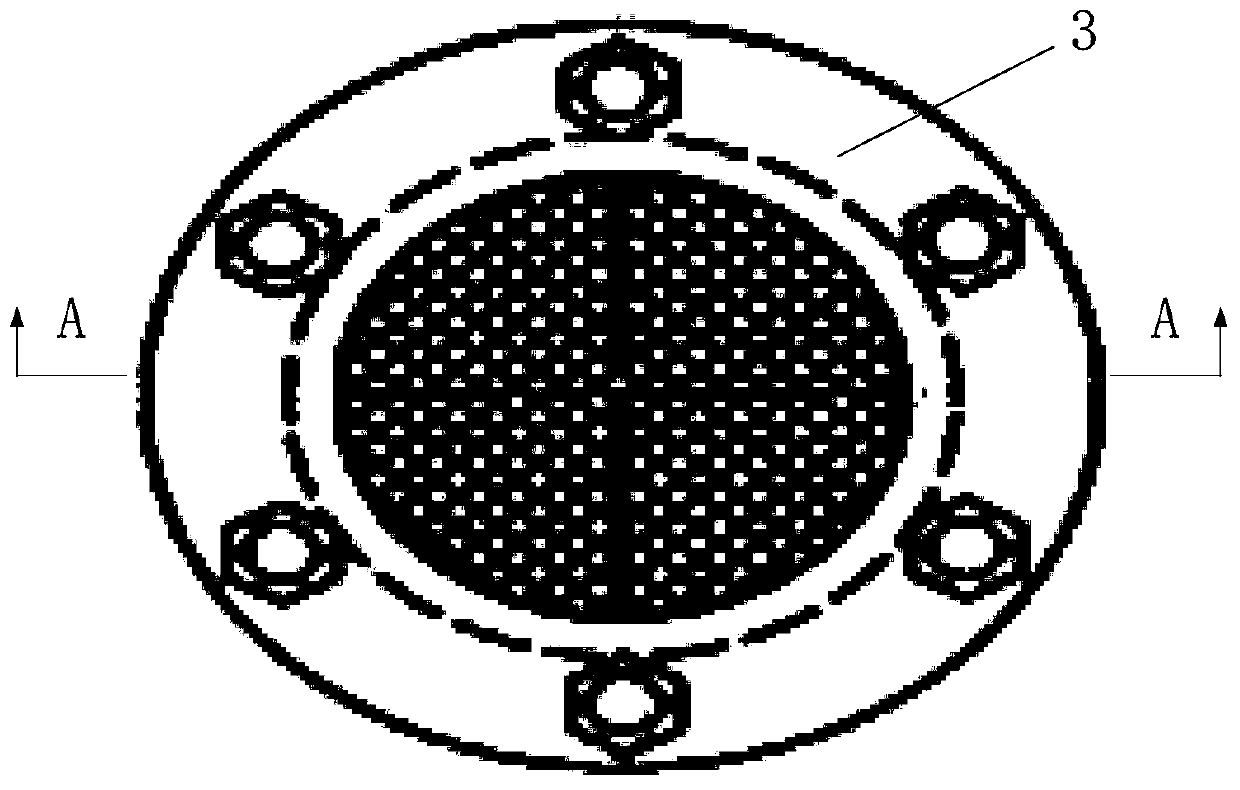

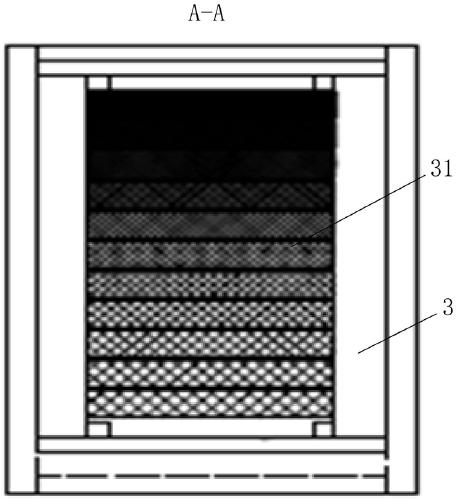

Method used

Image

Examples

Embodiment 1

[0043] The foam system is: 0.2% AP-P4+0.15% sodium alkylbenzenesulfonate, salinity 9300mg / L, temperature 65°C, back pressure 10MPa, gas-liquid ratio 1:1-5:1; under different gas-liquid ratios The results of the foam rheology test are shown in Table 1 below.

[0044] Table 1 The rheological properties of foam under different gas-liquid ratios

[0045]

Embodiment 2

[0047] The foam system is: 0.2% AP-P4+0.15% sodium alkylbenzene sulfonate, salinity 9300mg / L, gas-liquid ratio 2:1, back pressure 10MPa, temperature 45-95°C; foam rheology test at different temperatures The results are shown in Table 2 below.

[0048] Table 2 Foam rheological properties at different temperatures

[0049] temperature / ℃ Binary viscosity / mPa.s 7.34s -1 Foam High Pressure Viscosity / mPa.s

Embodiment 3

[0051] Foam system: 0.2% AP-P4+0.15% sodium alkylbenzene sulfonate, salinity 9300mg / L, gas-liquid ratio 2:1, temperature 65°C, back pressure 4-16MPa; foam rheological test results under different pressures As shown in Table 3 below.

[0052] Table 3 Rheological properties of foam under different pressures

[0053]

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com