Measurement device and measurement method for fresh mortar non-lateral-confinement bearing capacity

A measuring device and technology of bearing capacity, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of small bearing capacity, large deformation, and large magnitude difference of unconfined bearing capacity of freshly mixed mortar. Free height adjustment, simple structure, and the effect of eliminating uneven load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

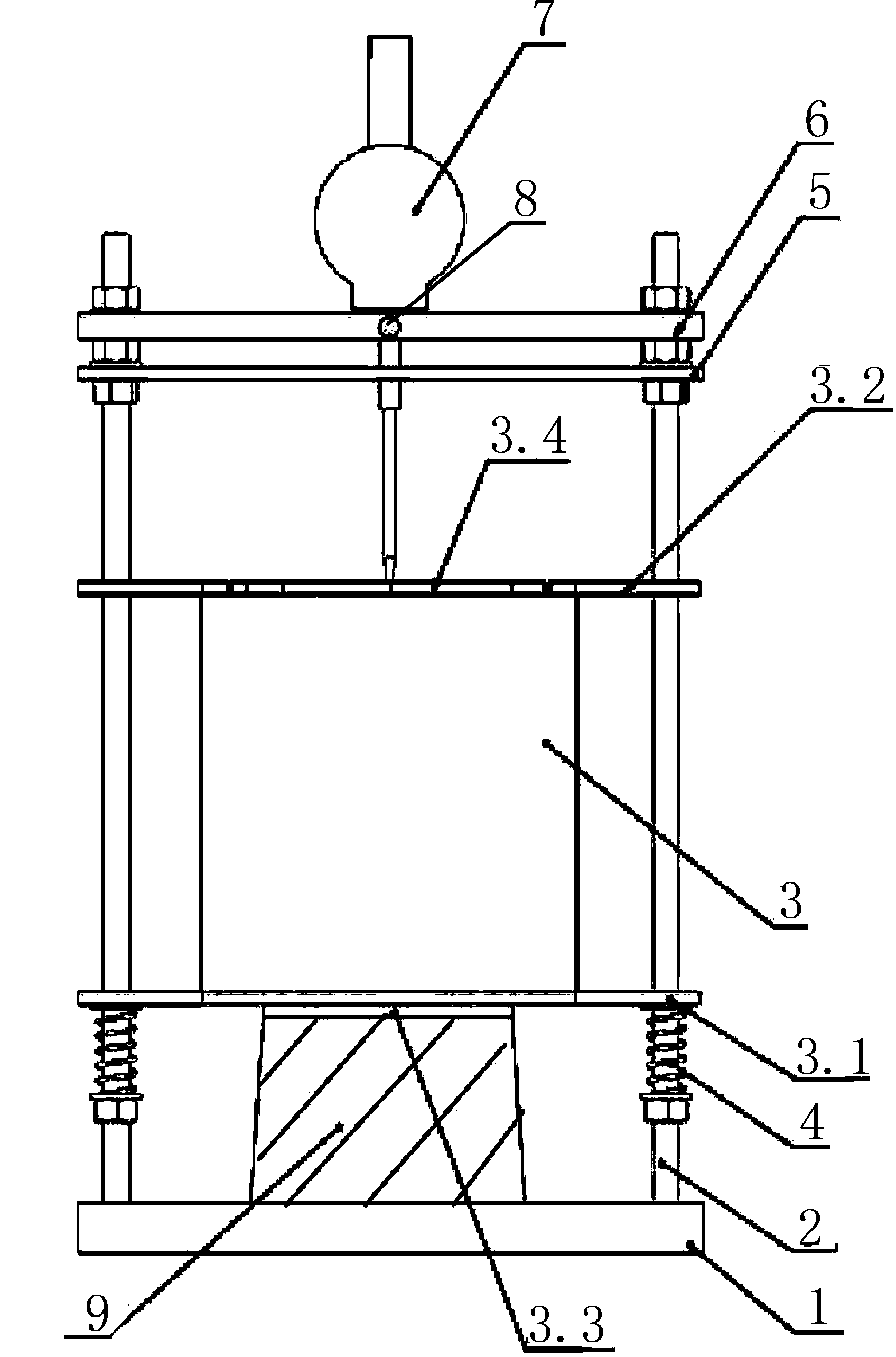

[0039] Examples see Figure 1-Figure 3 As shown, a device for measuring the unconfined bearing capacity of a freshly mixed mortar slurry includes three parts from bottom to top: a frame body, a loading device, and a vertical displacement measurement device; the frame body includes a base 1 , screw rod 2 and several nuts for installing the loading device and the vertical displacement measuring device.

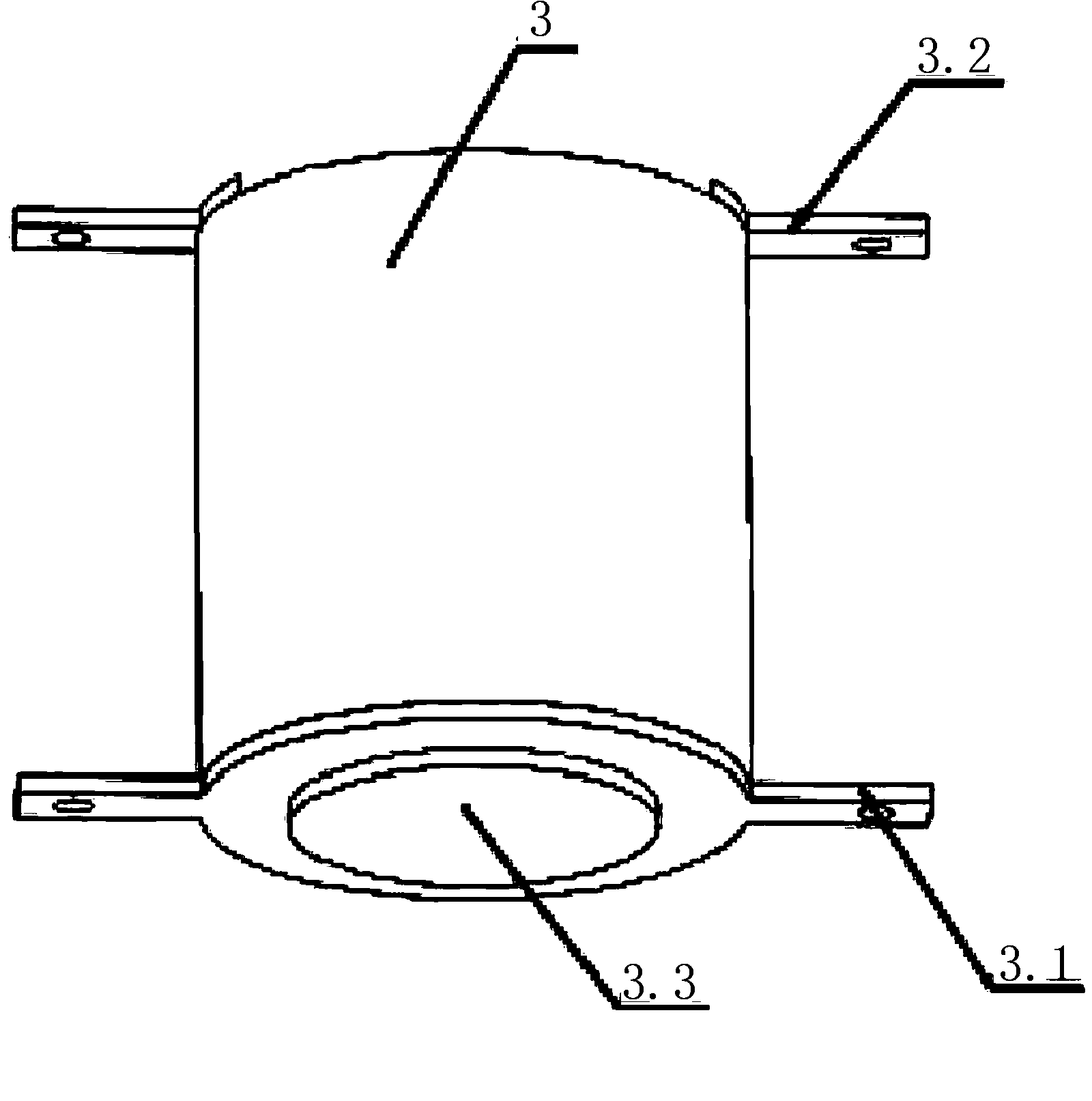

[0040] The loading device includes a loading bucket 3, the bottom sides of the loading bucket 3 are welded to the bottom side wings 3.1 of the loading bucket with screw holes, and the top sides of the loading bucket are connected to the loading bucket with screw holes. The top flank 3.2 of the bucket is welded and fixed, and the screw holes of the bottom flank 3.1 of the loading bucket and the top 3.2 of the loading bucket are in the same plane;

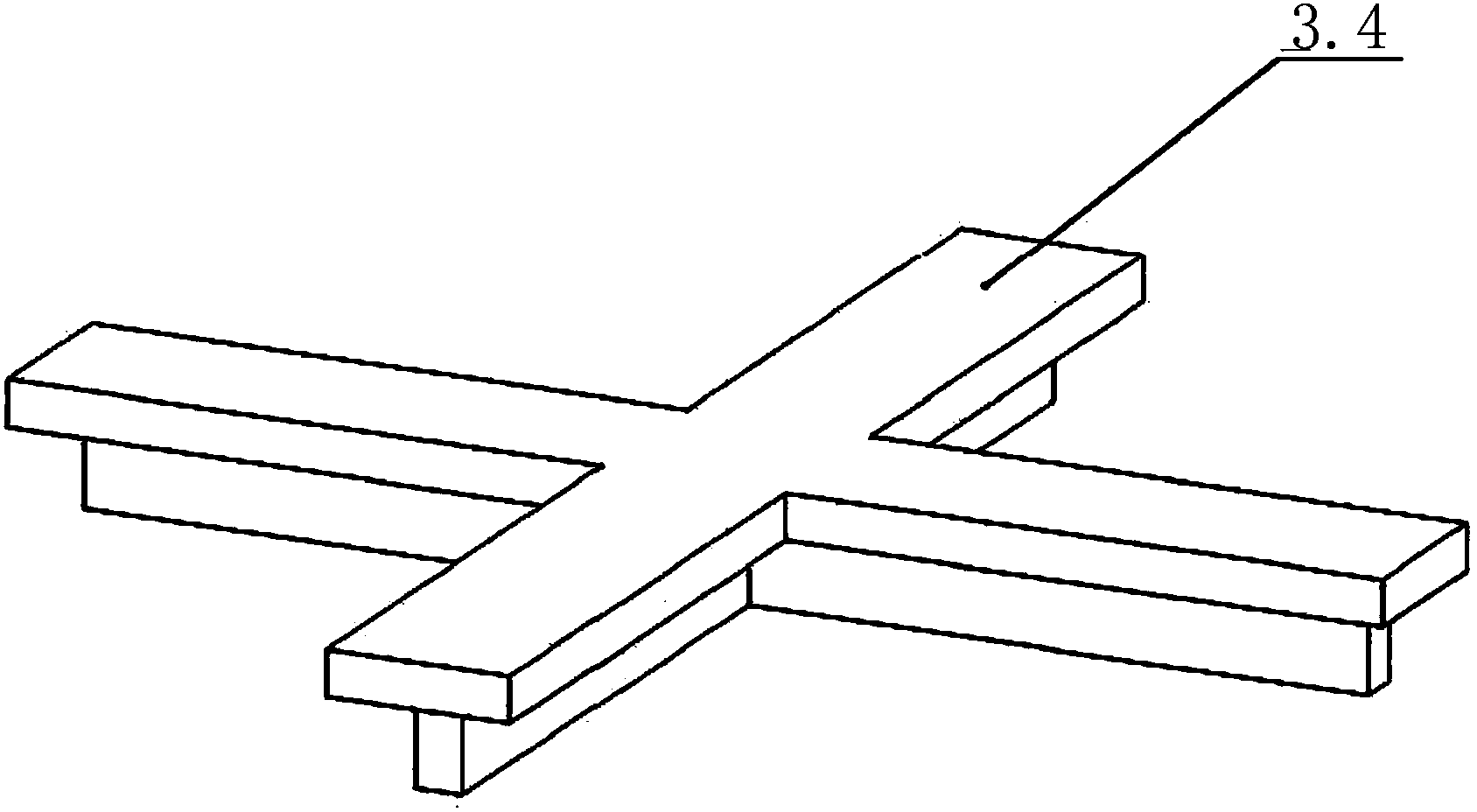

[0041] The bottom surface of the loading barrel 3 is provided with a loading plate 3.3, and the top of the loading barrel is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com