Device and method for parameter characteristic testing of magnetostrictive material

A technology of magnetostrictive materials and parameter characteristics, applied in magnetostrictive performance measurement, magnetic performance measurement, etc., can solve the problems of not measuring the output force and load force characteristics of materials, and achieve simple structure, few assembly parts, and uniform improvement sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

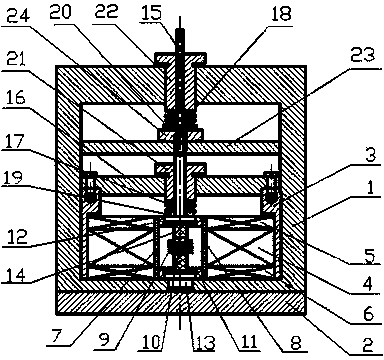

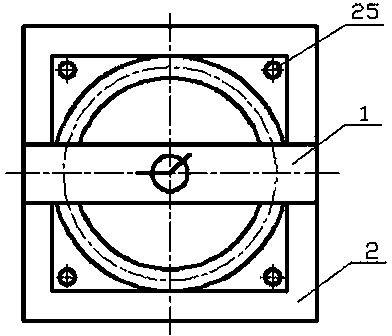

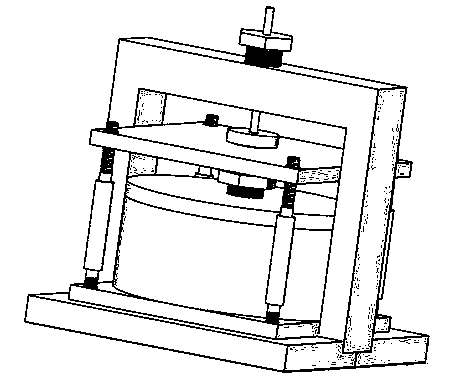

[0024] like figure 1 As shown, the magnetostrictive material parameter characteristic testing device includes a frame 1, a base 2, a casing 3, a first coil 4, a second coil 5, a third coil 6, a coil bobbin 7, a temperature sensor 8, a detection coil 9, a Hall Sensor 10, first clamping copper sleeve 11, second clamping copper sleeve 12, lower plug 13, magnetostrictive material to be tested 14, ejector rod 15, upper end cover 16, first disc spring 17, second disc spring 18. The first pressure sensor 19, the second pressure sensor 20, the first adjustment nut 21, the second adjustment nut 22, the cover plate 23, the cover plate nut 24, the screw rod 25; The groove is provided with a frame 1 fixed by screws, the lower end of the frame 1 is provided with a lower plug 13, the upper end of the frame 1 is provided with a second adjustment nut 22, and the push rod 15 passes through the second adjustment nut 22, the second disc spring 18, the second The pressure sensor 20, the cover pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com