High-robustness geometric correction method adapted to random projector group and projection screen

A technology for projection screens and projectors, which is applied to parts of color TVs, parts of TV systems, and image data processing, etc., can solve the problems of lack of high-robust projection, high-speed fusion and drive technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The invention provides a correction method suitable for large-scale projector groups and arbitrary projection screens.

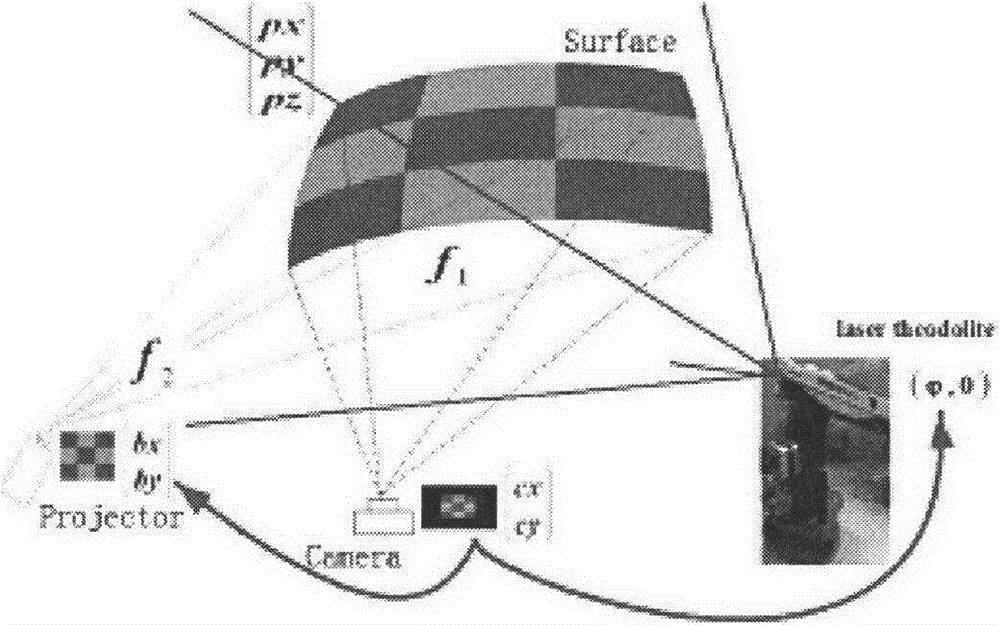

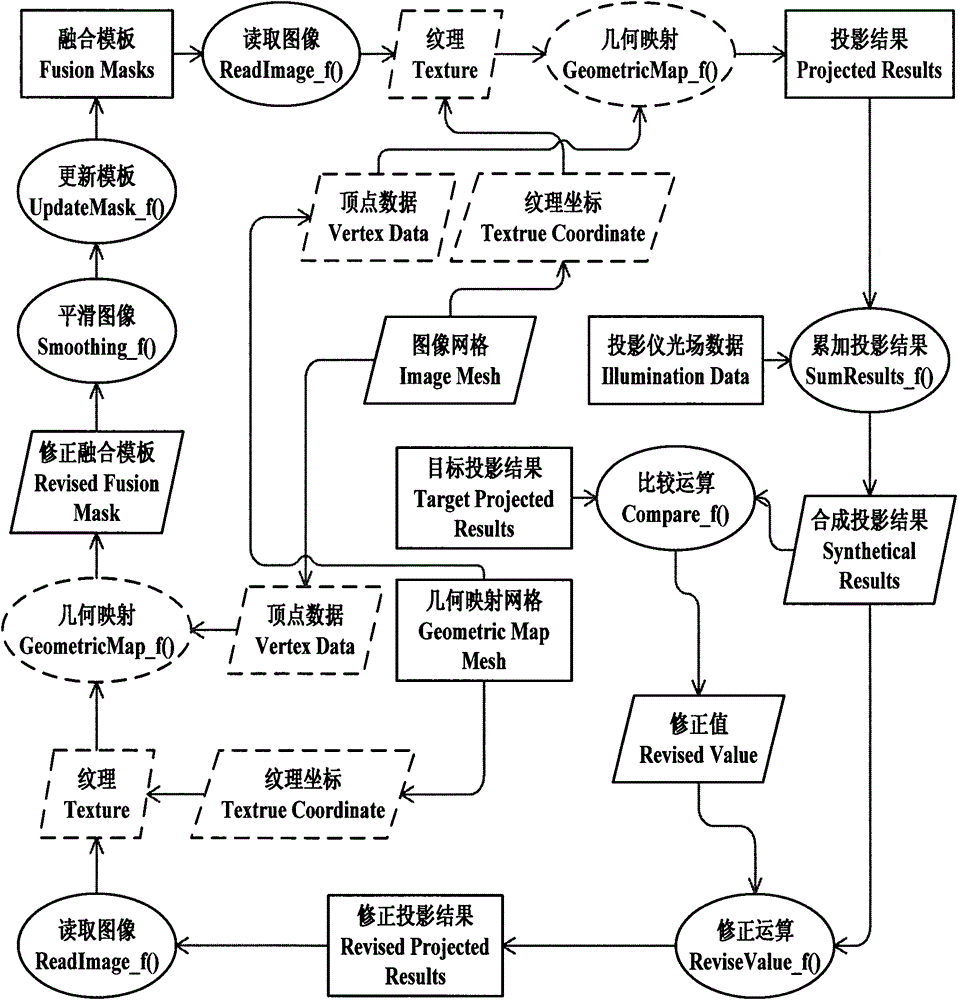

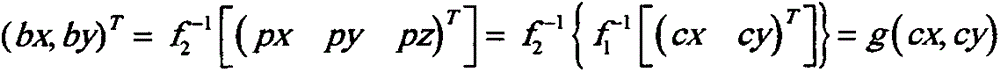

[0038] The present invention intends to establish a fine mapping relationship between the projection feature image and the multi-view image of the camera, so as to form a grid of the incident light angle coordinate relationship of each pixel in the projection image relative to the observation point, so that the complex three-dimensional geometric calibration problem becomes relative A simple two-dimensional geometric calibration problem. On this basis, with the help of high dynamic range imaging technology, ordinary cameras and low-precision pan / tilts can be used to measure the color information of each pixel position of the projector, and a mathematical model of light field distribution on the entire projection screen can be established. The optimization solution technology independently completes the high-speed calculation process of color correctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com