Nitride Semiconductor Device And Method Of Manufacturing The Same

一种氮化物半导体、制造方法的技术,应用在半导体/固态器件制造、半导体器件、电气元件等方向,能够解决局限性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

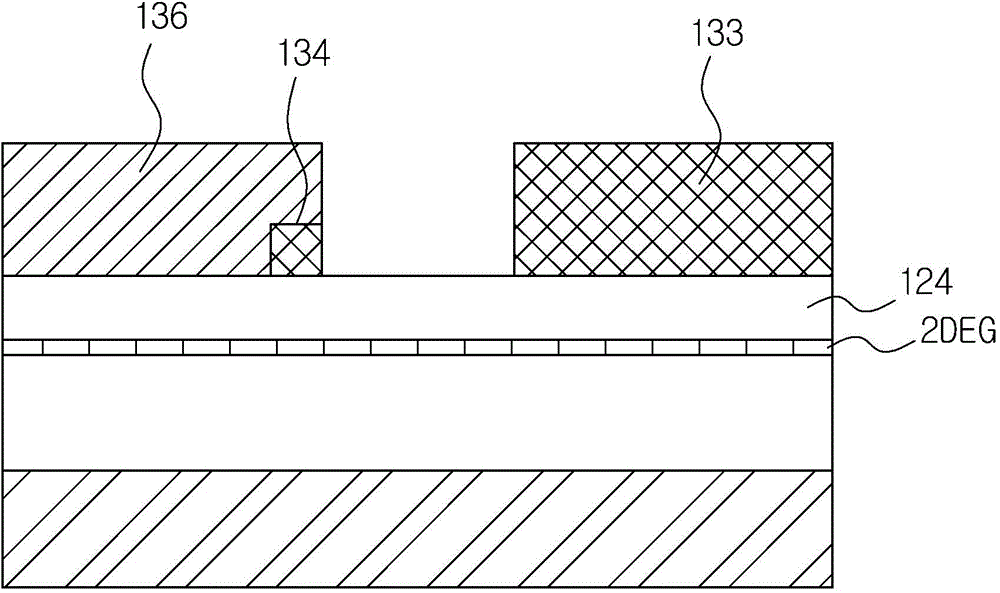

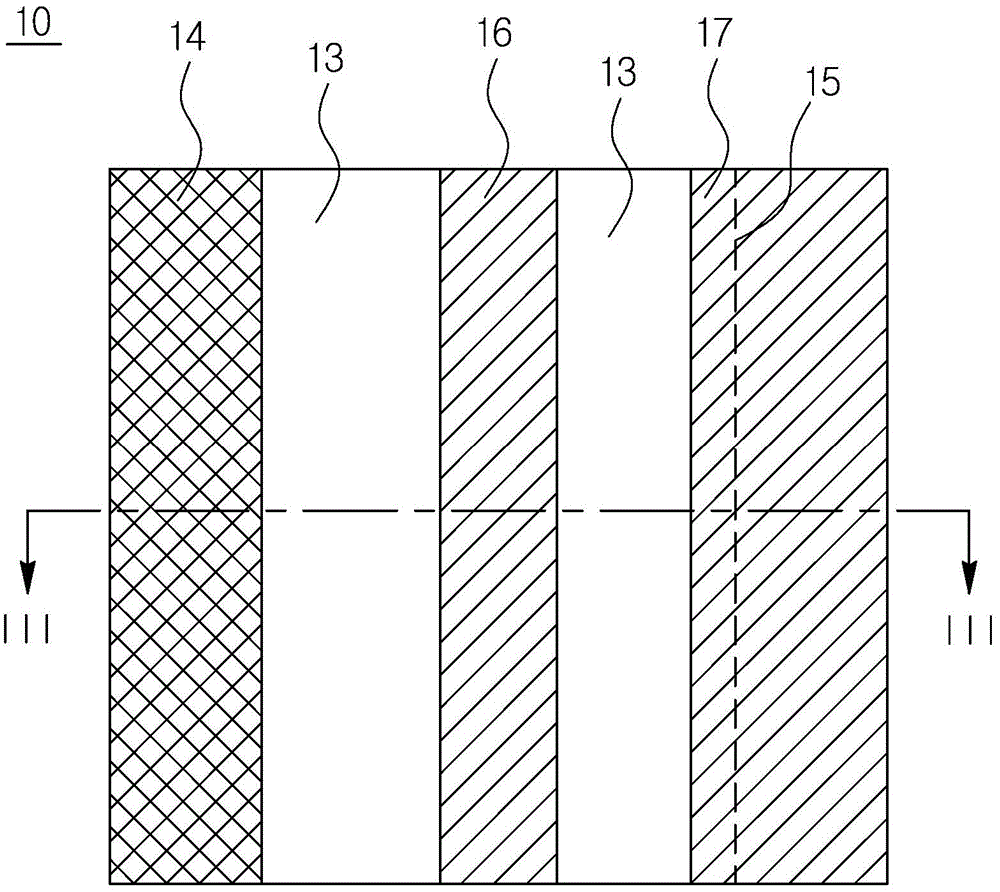

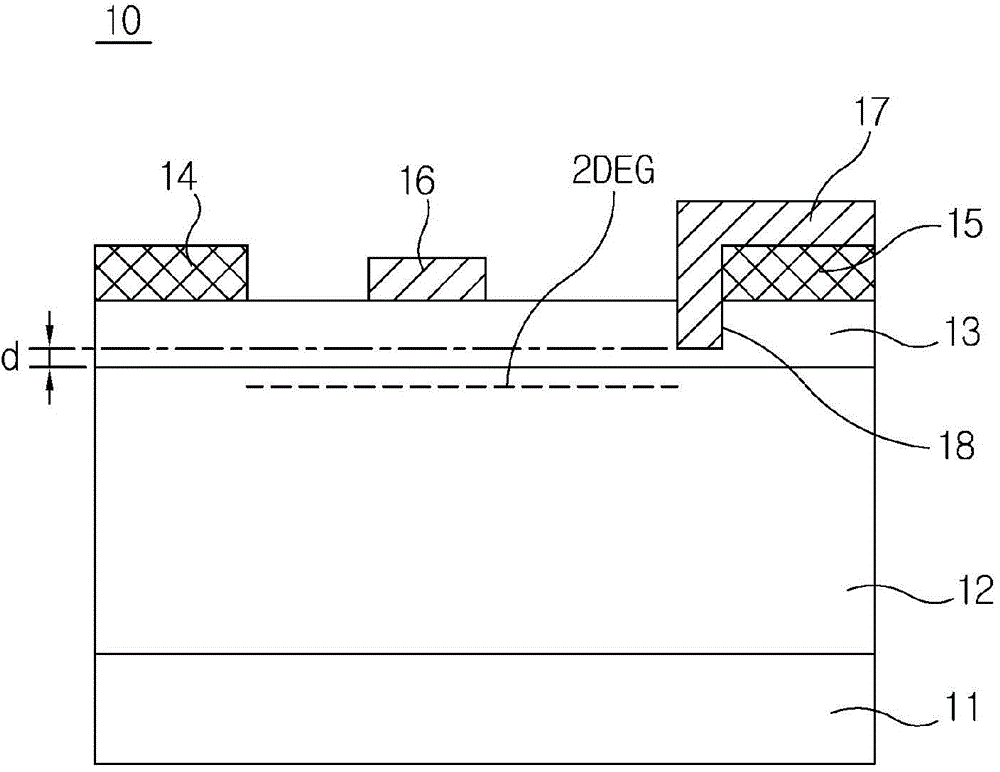

[0092] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. For clarity and convenience of description, the width of lines or the size of constituent elements and the like shown in the drawings may be exaggerated.

[0093] The embodiments to be described below are provided as examples in order to fully convey the idea of the present invention to those skilled in the art to which the present invention pertains. Therefore, the present invention is not limited to the Examples described below, and may be embodied in other forms. In addition, in the drawings, for convenience of illustration, the width, length, thickness, etc. of the constituent elements may be expressed exaggeratedly. In addition, when it is stated that one constituent element is located "on" or "on" other constituent elements, it includes not only the case where each part is located "immediately above" or "immediately above" other parts, but als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com