Processing technique for speaker frame with different shapes of ear holes

A technology of speaker basin frame and processing technology, which is applied to sensors, electrical components, etc., can solve the problems of high defective product rate, unrealizable process method, and low dimensional control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

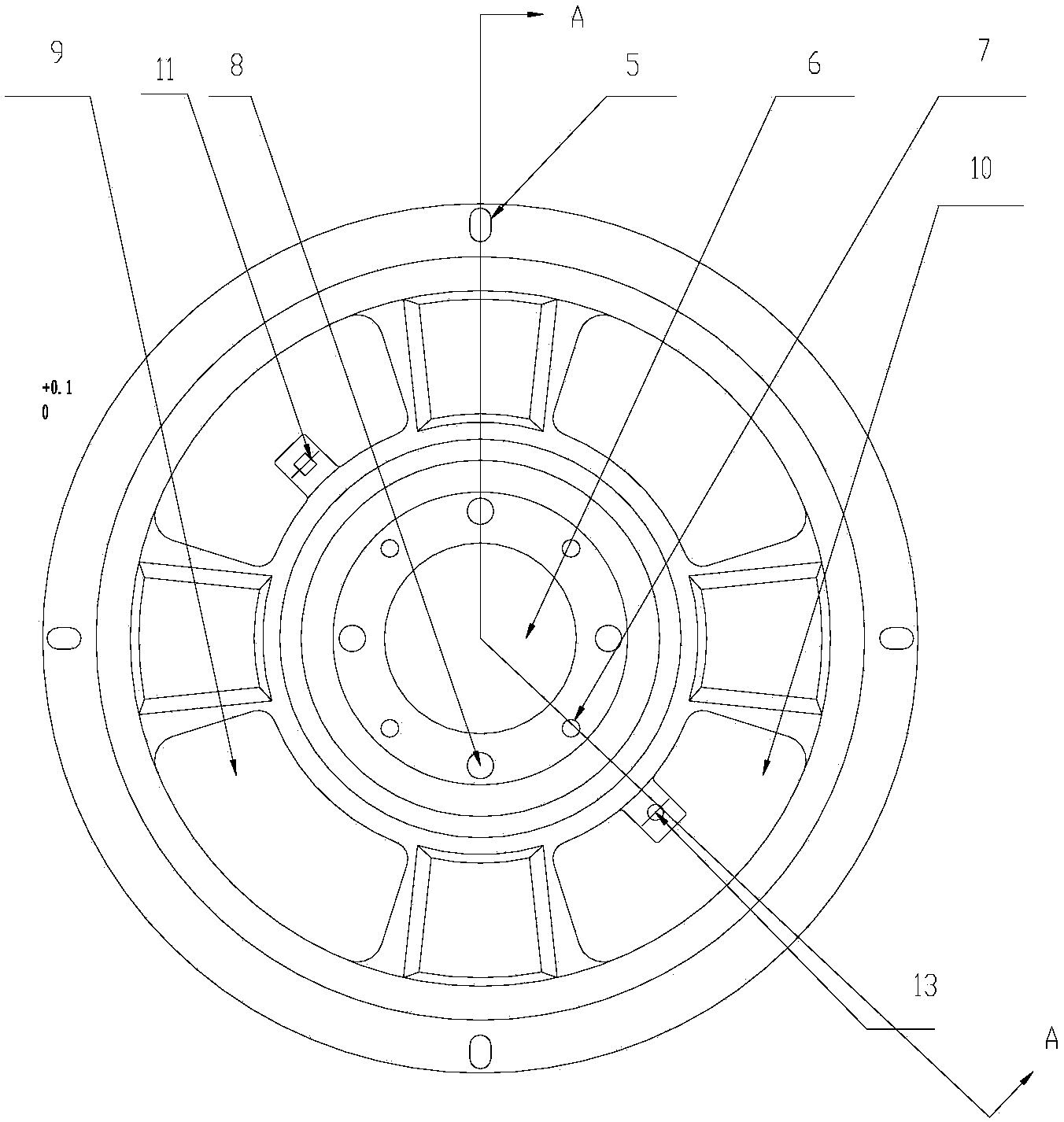

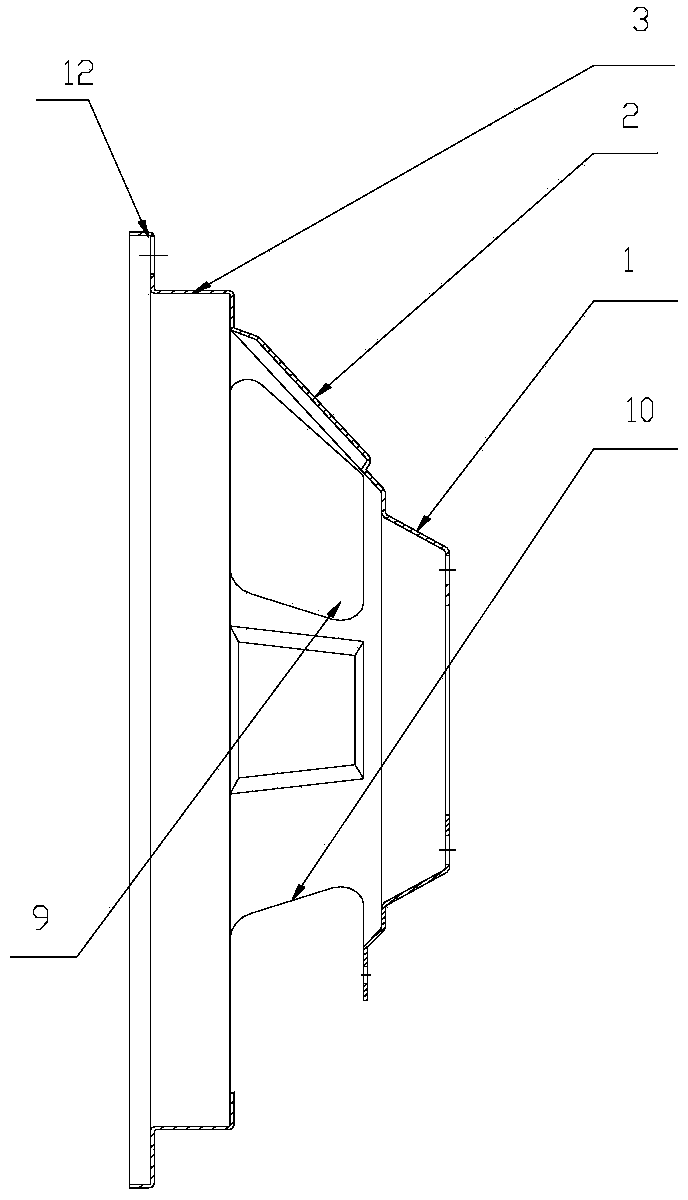

[0023] Such as figure 1 and figure 2 Shown, a kind of processing technology of the loudspeaker frame with the ear hole of different shapes, comprises the following steps:

[0024] Step 1: cutting, cutting out a piece of square raw material with a side length of 246 mm by a shearing machine;

[0025] Step 2: Punch a positioning hole, and punch out a positioning hole with a diameter of 20 mm in the center of the square raw material through the positioning hole die;

[0026] Step 3: Stretching. The square raw material is stamped into a bowl-shaped semi-finished product through the stretching die with the center of the positioning hole as the center. The inner diameter of the bowl-shaped semi-finished product increases sequentially from bottom to top. The bowl-shaped semi-finished product is composed of three steps from bottom to top. The three steps include a first step 1 with a height of 10.5-11.5 mm, a second step 2 with a height of 1.8-2.2 mm, A third step 3 with a height ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com