a small harvester

A harvester, a small technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems affecting the normal operation of the upper and lower scissors, restricting the application of the crawler drive system, hindering the movement of the cut straws, etc. The effect of normalization, increased contact area with the ground, and improved passing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A kind of embodiment of the present invention is described below in conjunction with accompanying drawing:

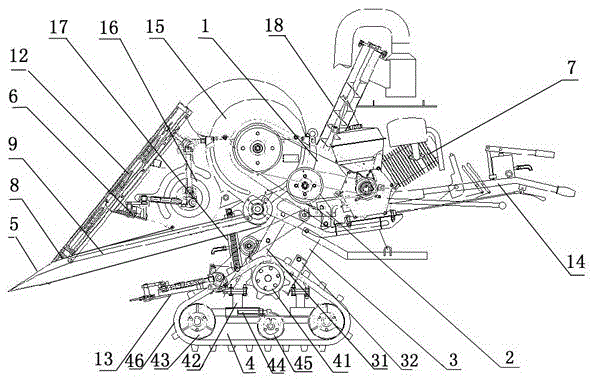

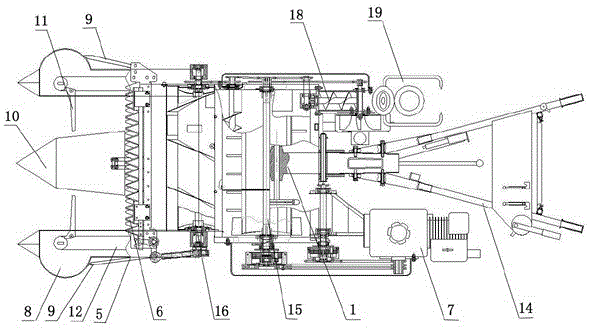

[0027] Such as figure 1 As shown, a small harvester includes a harvester main body 1, a load-bearing bracket 2, a gearbox 3, a walking mechanism 4 and a holding claw assembly 5; the harvester main body 1 is hinged with a load-bearing bracket 2, and the load-bearing bracket 2 The gearbox 3 is connected, and the gearbox 3 is connected with the traveling mechanism 4; the gearbox front bearing 31 and the gearbox rear bearing 32 can be installed on the gearbox 3 and the traveling mechanism 4 to strengthen the support; The main body 1 of the harvester includes an upper scissors assembly 6 and a driving device 7; the helper claw assembly includes a support seat 8, a support rod 9, a fork 10, a claw 11 and a chain transmission Mechanism 12; said supporting seat 8 is arranged on the left and right sides of the main body of the harvester respectively, and its bottom is cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com