Impeller type dish washing machine and control method thereof

A control method and dishwasher technology, applied to the washing machine/rinsing machine of tableware, the parts of washing machine/rinsing and rinsing machine of tableware, cleaning equipment, etc., which can solve the difficulty of cleaning, cannot use ordinary detergent, and takes a long time to clean and other problems, to achieve the effect of simple and convenient operation, shortened cleaning time and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments, but this does not constitute any limitation to the present invention.

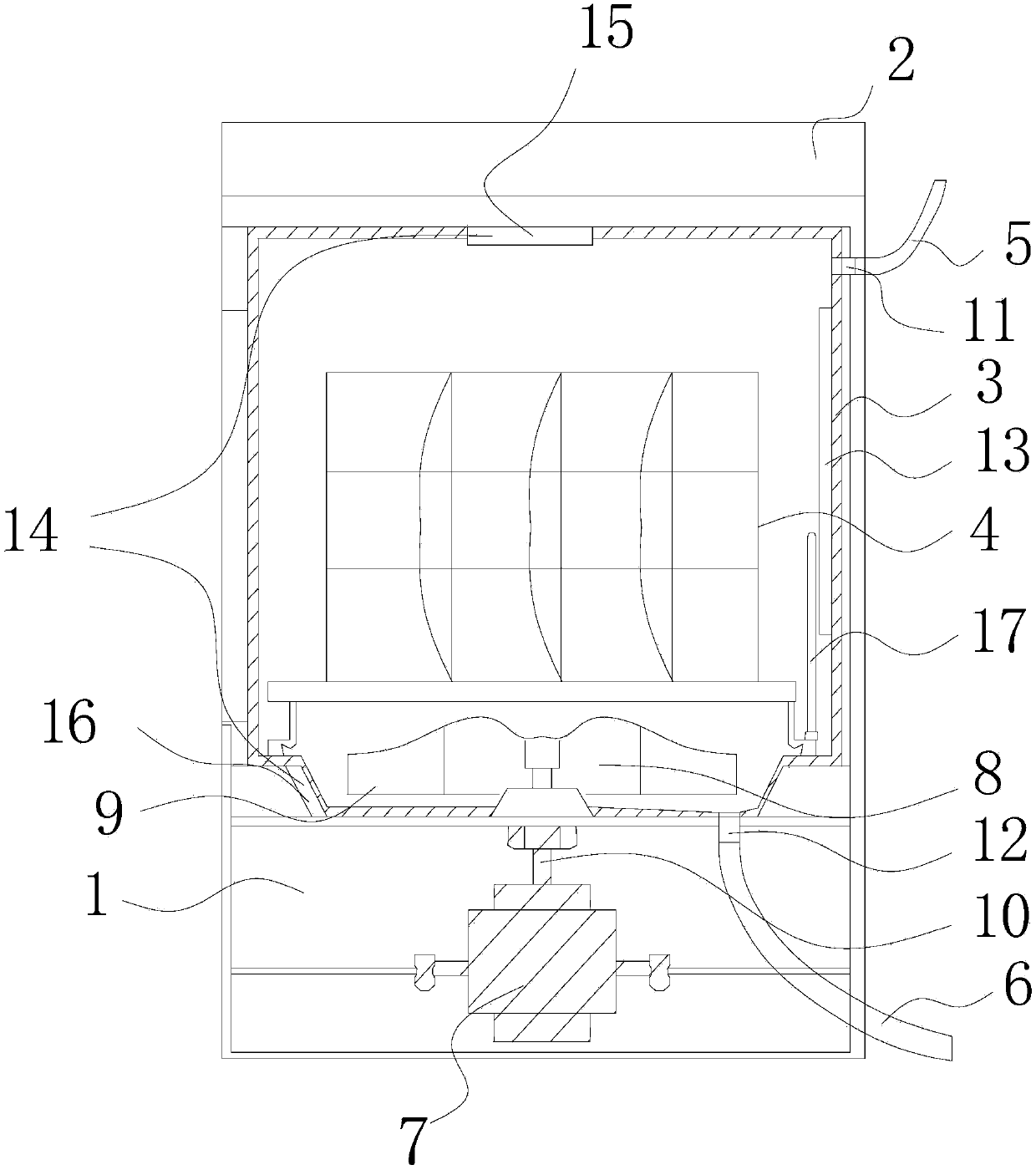

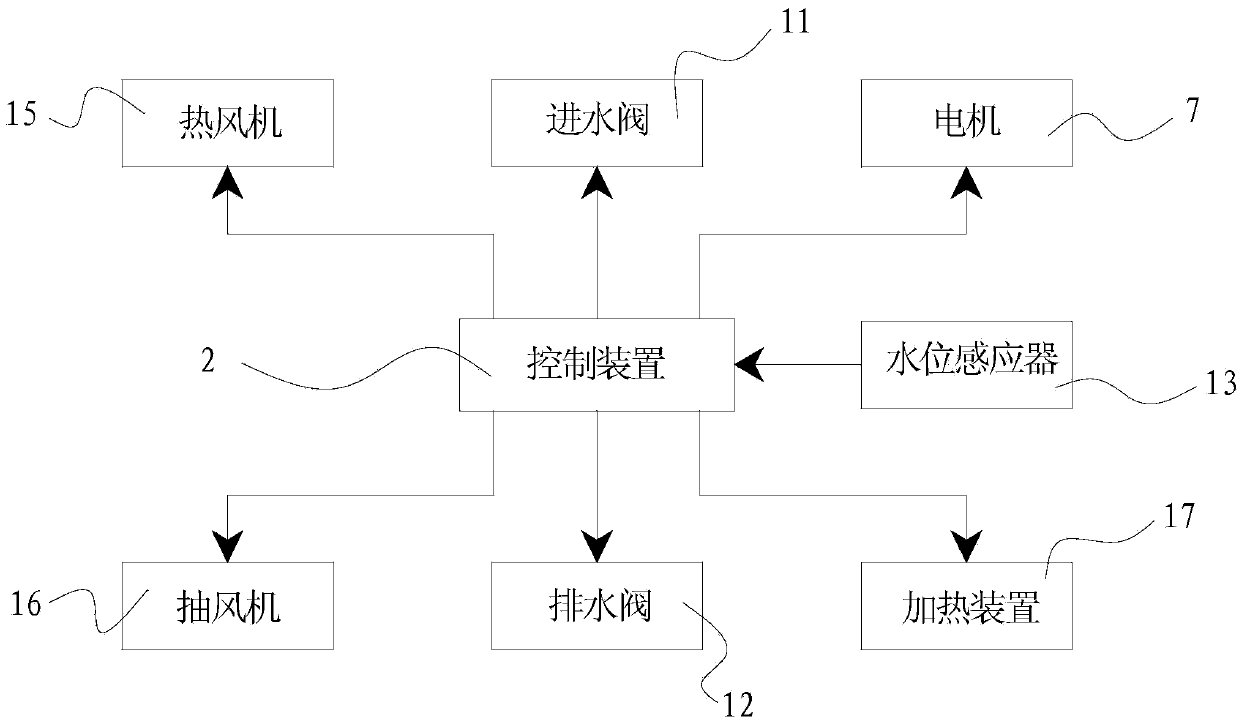

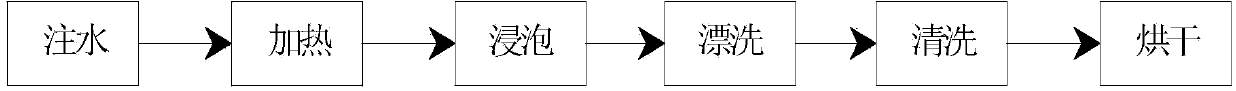

[0030] refer to figure 1 , 2 As shown, a pulsator type dishwasher comprises a box body 1, a control device 2 is arranged on the upper part of the box body 1, a washing chamber 3 is arranged in the box body 1, and a bowl basket 4 is installed on the washing chamber 3, and a washing chamber 4 is installed on the washing chamber 3. The upper and lower parts of the cavity 3 are provided with water inlet pipe 5 and water outlet pipe 6 correspondingly and extend to the outside of the box body 1, wherein a motor 7 is installed at the bottom of the box body 1, and the motor 7 adopts a two-stage adjustable speed motor. A rotating shaft 8 is provided at the bottom of the washing chamber 3 and an impeller 9 is respectively installed at both ends of the rotating shaft. The angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com