A kind of ligament support and preparation method thereof

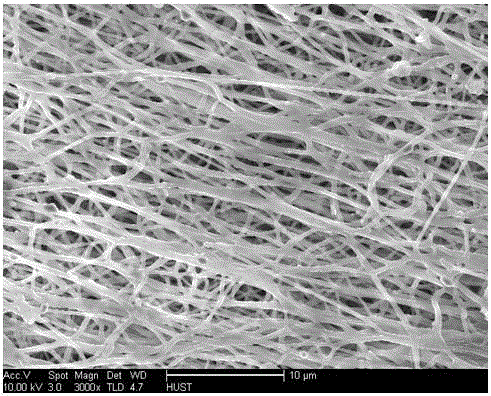

A technology of ligament and silk fibroin, which is applied in the field of medical devices to achieve the effect of uniform microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] Preparation of ligament stent, prepare silk fibroin solution or silk fibroin powder dispersion and medical polymer synthetic material polyvinyl alcohol (PVA) solution or polyurethane (PU) solution or polycaprolactone solution (PCL) or polyurethane ( After mixing the solution of PU) and polycaprolactone (PCL), proceed as follows:

[0018] a. Mix the silk fibroin solution or silk fibroin powder dispersion with the medical polymer synthetic material solution to obtain a mass ratio of silk fibroin to medical polymer synthetic material of 1 / 20~1 / 1. The polymer composite material has a mixed solution with a total solute mass concentration of 7% to 15%, and the mixed solution is sucked into a spinning dope tube for electrostatic spinning.

[0019] b Set up an electrospinning device, and fix the collecting wheel with the circumference of 1 to 3 times the length of the ligament to be prepared on the adjustable-speed conductive rotating body. The collecting wheel and the conductive ro...

Embodiment 1

[0027] a Mix hexafluoroisopropanol as a solvent and a 5% mass concentration of silk fibroin solution with N,N-dimethylformamide as a solvent and a 20% mass concentration polyurethane (PU) solution to obtain silk fibroin and The mass ratio of medical polymer synthetic material polyurethane (PU) is 1 / 20, the total solute mass concentration of silk fibroin and medical polymer synthetic material polyurethane (PU) is 7%, and the mixed solution is sucked into electrostatic spinning Of spinning solution tube.

[0028] b. Set up an electrospinning device, and fix the collecting wheel with a circumference of 1 times the length of the ligament to be prepared on an adjustable-speed conductive rotating body. The collecting wheel and the conductive rotating body are on the same axis, and the collecting wheel is made of electrically insulating material. , The thickness of the collecting wheel is 1mm, and the two sides of the collecting wheel are respectively attached with conductive metal disc...

Embodiment 2

[0032] a Mix hexafluoroisopropanol as a solvent with a 10% mass concentration of silk fibroin solution and dimethylacetamide as a solvent with a mass concentration of 10% polycaprolactone (PCL) solution to obtain silk fibroin and medical The mass ratio of polymer synthetic material polycaprolactone (PCL) is 1 / 10, and the total solute mass concentration of silk fibroin and medical polymer synthetic material polycaprolactone (PCL) is a mixed solution of 10%, and will be mixed The solution is sucked into the spinning dope tube for electrospinning.

[0033] b. Set up an electrospinning device, and fix the collecting wheel twice the circumference of the length of the ligament to be prepared on the adjustable-speed conductive rotating body. The collecting wheel and the conductive rotating body are on the same axis, and the collecting wheel is made of electrically insulating material. , The thickness of the collecting wheel is 3mm. The two sides of the collecting wheel are respectively ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com