Multi-station punching machine

A multi-station, punching technology, applied in the field of stamping press machines, can solve the problems of worker injury, hidden dangers, fast stamping action, etc., and achieve the effect of reducing labor intensity, safe operation and use, and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

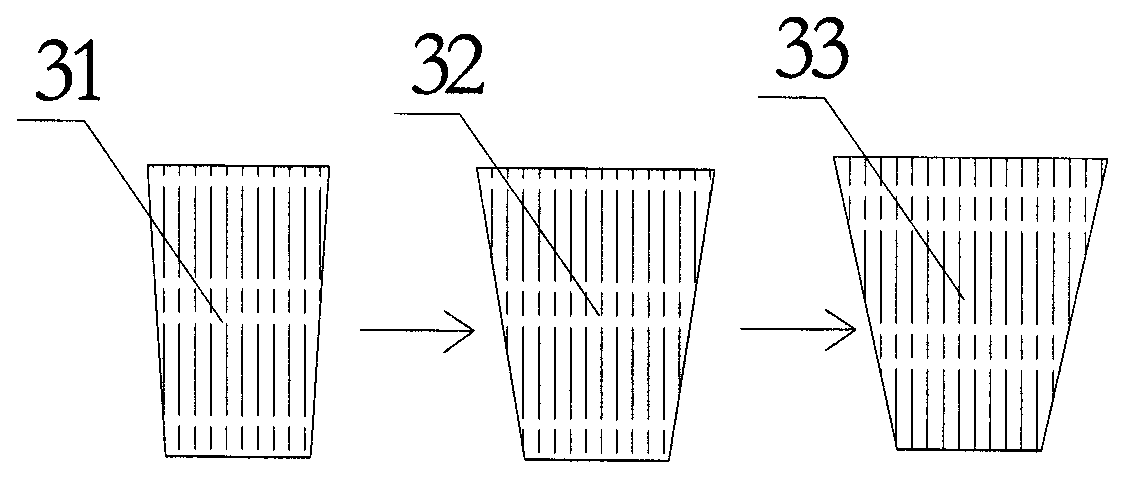

[0037] Such as Figure 4-5As shown, a multi-station punch press includes a punch main body 4, a die device 5, a stamping power unit 6 and a control device 7 are arranged on the punch main body 4, and at least two Guide post 41, the guide post 41 is vertically arranged and evenly distributed relative to the horizontal plane, the power output end of the stamping power device 6 is connected to the die device 5, and the die device 5 is sleeved and slidably installed on the guide On the column 41 and under the drive of the stamping power device 6, it reciprocates longitudinally on the guide column 41 perpendicular to the horizontal plane. The die device 5 is provided with two or more than two punches 51, and the punches 51 Arranged in sequence according to the slope of the punching head, the punch body 4 is also provided with a lower die 42, the lower die 42 is horizontally arranged and opposite to the die device 5, and the workpiece to be processed is vertically arranged relative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com