Converter water seal check valve liquid level detection device

A technology of liquid level detection and check valve, applied in furnaces, furnace components, manufacturing converters, etc., can solve problems such as safety accidents, detection errors, false signal output of water level gauges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

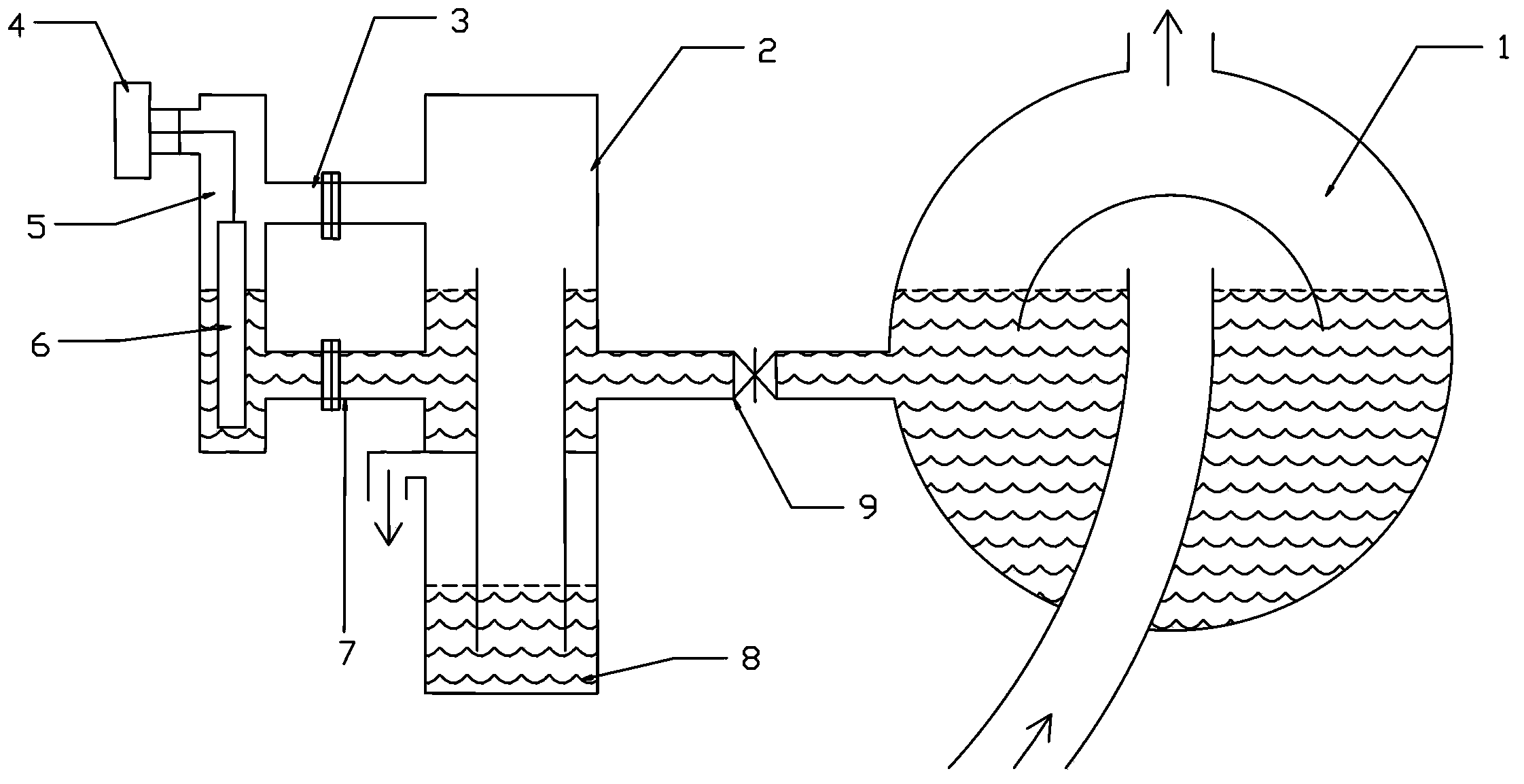

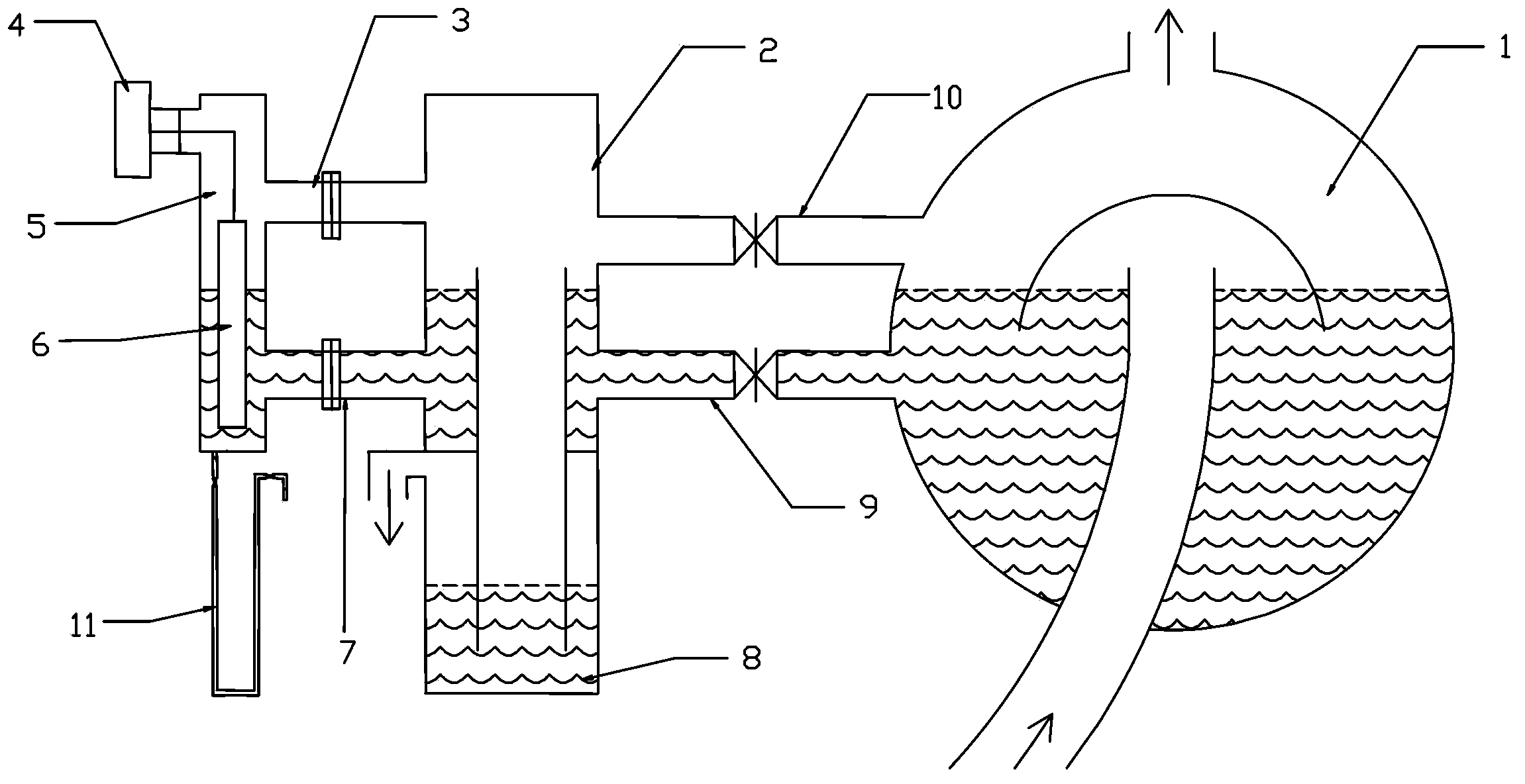

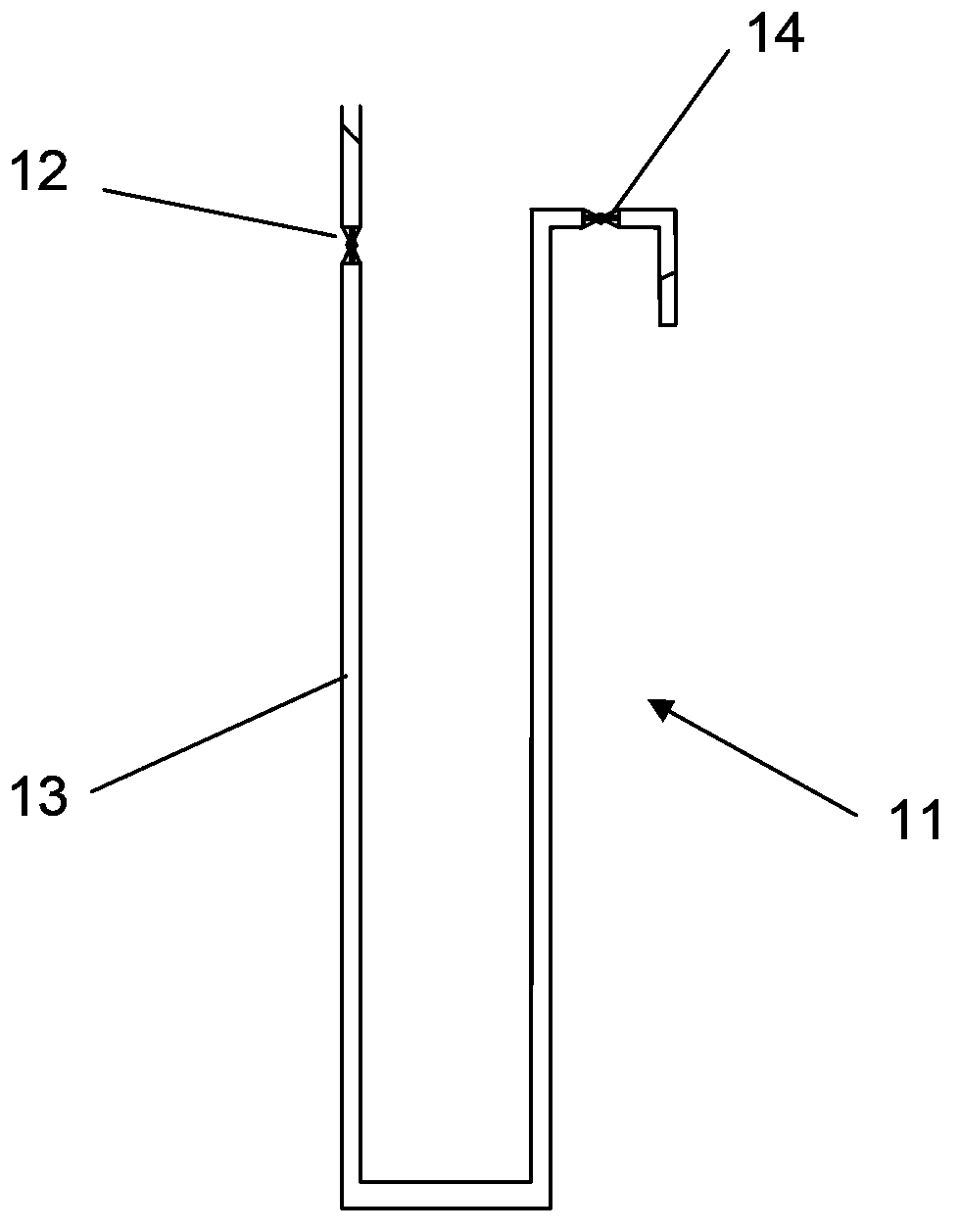

[0017] see Figure 2 ~ Figure 3 As shown, the converter water seal check valve liquid level detection device of the present invention is basically the same as the prior art, and also includes a balance water level overflow chamber 2 connected to the converter water seal check valve 1 through the water seal valve water connecting pipe 9 , connected to the water-sealed water level overflow chamber 8 located below the balance water level overflow chamber 2, and the measuring water cylinder 5 connected to the balance water level overflow chamber 2 through the water level gauge water connection pipe 9 and the water level gauge gas connection pipe 3 respectively, and is located in The buoy 6 in the measurement water tank 5 and the signal detection conversion device 4 connected with the buoy 6 are the same, so they will not be repeat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com