Ultra-soft wearproof velveteen-like fabric and preparation process thereof

A technology of imitation velveteen and fabrics, applied in the field of supersoft and wear-resistant imitation velveteen fabrics and its preparation technology, which can solve the problems of easy shedding of fluff and affect the use, and achieve the effect of long-lasting velvet feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific embodiments.

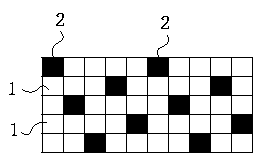

[0019] Such as figure 1 As shown, the super soft and wear-resistant imitation velveteen fabric is made of warp yarn 2 and weft yarn 1; the warp yarn is 50D / 72F superfine polyester elastic yarn, and the ground weft yarn is 75D / 24*12F polyester Brocade high-shrinkage silk; the weave pattern is five pieces of satin, and the high shrinkage of the high-shrinkage yarn makes the floating length of the five pieces of satin shrink into loops, so that it has the style and feel of velveteen. The fabric is relatively plump and soft, with a silky feel, which breaks through the phenomenon of velveteen in the past, where the fluff is easy to fall off, and this product has a long-lasting velvet feel that is not easy to fall off and has the function of moisture absorption and perspiration.

[0020] The preparation process of the supersoft wear-resistant imitation velveteen fabric comprises...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com