Quick-dry cloth with dry single face for wet conduction

A fabric and dry technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problem of fabrics not being able to quickly dry and dry moisture, achieve soft touch, maintain skin, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings.

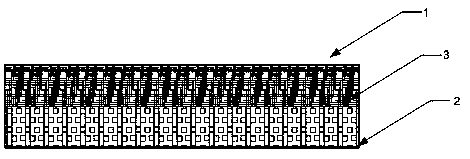

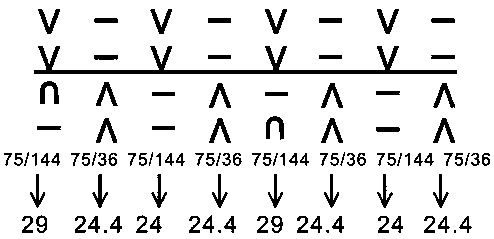

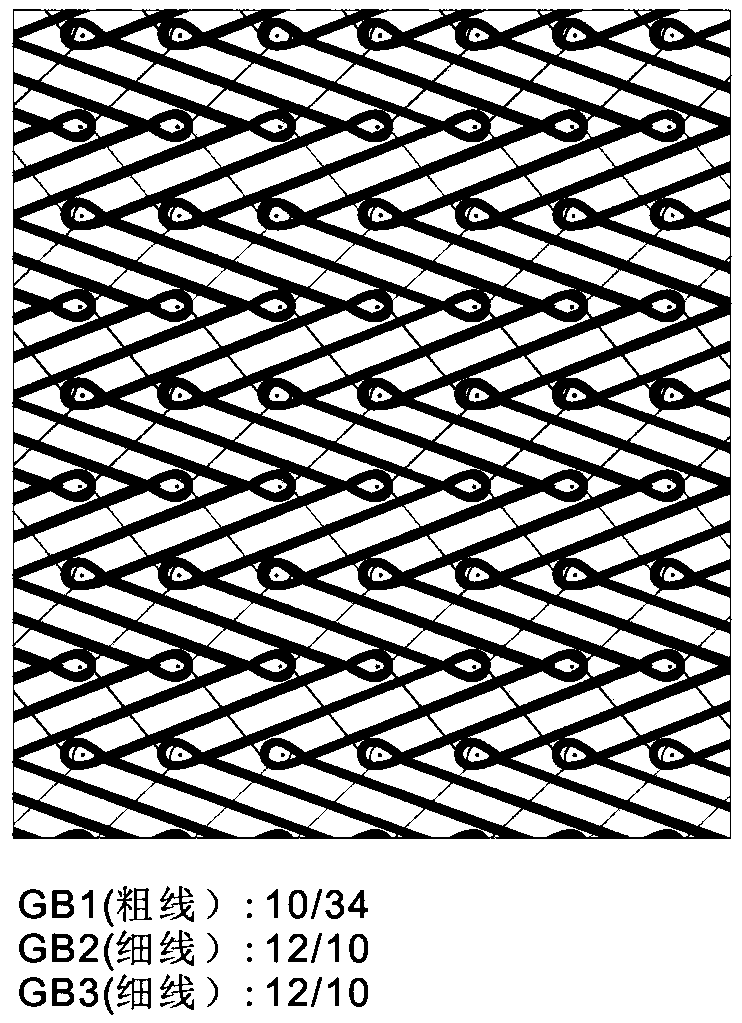

[0015] combined with figure 1 , a quick-drying fabric that is dry and moisture-conducting on one side, which includes a fabric body 1, the fabric body 1 includes an inner layer 2 and an outer layer 3, and the inner layer 2 is superfine polyester (including modified polyester) long Filament, or superfine nylon filament, the fineness (DPF) of single fiber is less than 0.7, the outer layer 3 is ordinary fineness polyester (including modified polyester) filament, or ordinary fineness nylon filament, single The denier (DPF) of the fibers is greater than 2.0.

[0016] As an improvement, the outer layer can also be any one of conventional chemical fiber materials, conventional natural fiber materials and man-made fiber materials.

[0017] As an improvement, the inner layer may be the remaining chemical fiber filaments with a fiber fineness (DPF) of less than 0.7. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com