Novel hydro-pneumatic spring

An oil-gas spring, a new type of technology, used in springs, springs/shock absorbers, gas-liquid shock absorbers, etc., can solve the problems of damping valves being easily affected by oil movement, and metal valve plates being easily fatigued and damaged. Simple, low-volume, compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

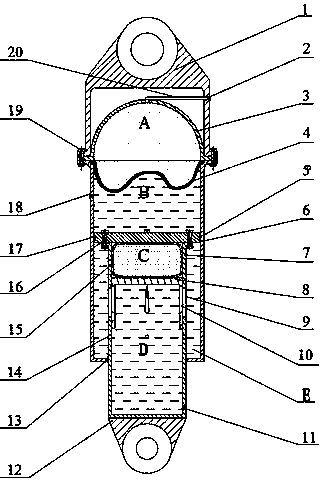

[0019] see figure 1 The overall structure sectional view of the present invention, the upper end of the present invention is the upper ring fixing device 1, the middle is the working cylinder 5, the lower end is the lower ring fixing device 12, and the lower end of the upper ring fixing device 1 is fixedly connected to the working cylinder through a threaded assembly 19 5, the upper ring fixing device 1 is hinged with the vehicle frame, and the lower ring fixing device 12 is hinged with the vehicle axle.

[0020] A piston 6 is installed in the inner chamber of the working cylinder 5, the piston 6 is fixedly connected to the upper end of the piston rod 7, the lower end of the piston rod 7 protrudes downwards outside the working cylinder 5, and the lower end of the piston rod 7 is fixedly connected to the lower ring fixing device 12 . Use sealing ring 13 to seal at the junction of piston rod 7 side walls and working cylinder barrel 5 lower bottom surfaces. The outer wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com