Cascading air-cooling composite single-effect and double-effect type lithium bromide absorption refrigerating machine

An absorption refrigerator, single-effect technology, applied in the direction of refrigerators, refrigeration components, adsorption machines, etc., can solve the problems of high temperature of circulating cooling water, water shortage restrictions, difficult production, etc., to ensure stable operation, The effect of stabilizing the condensation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

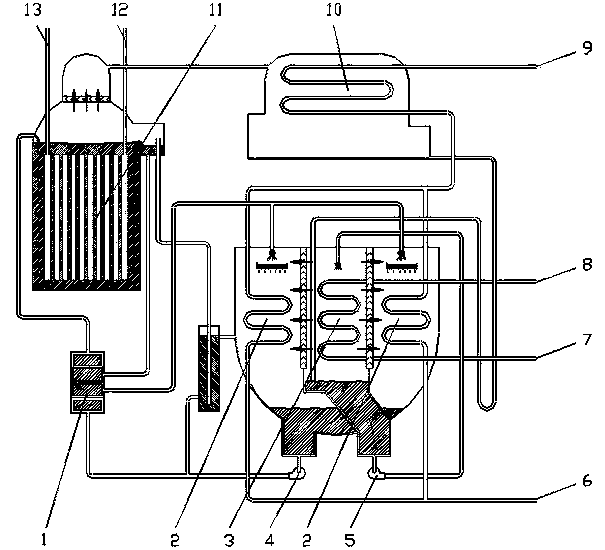

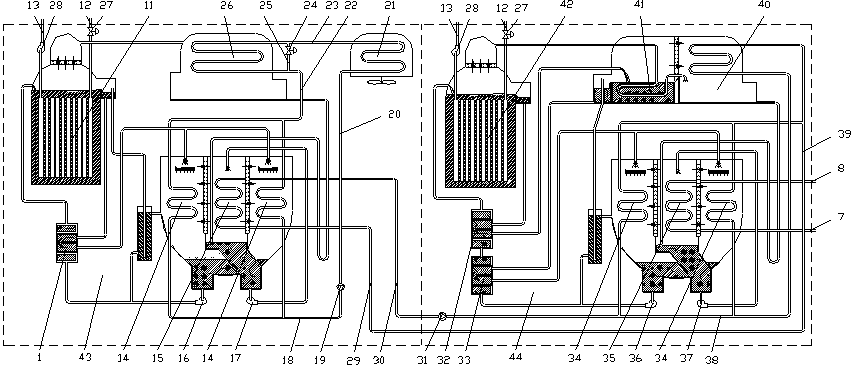

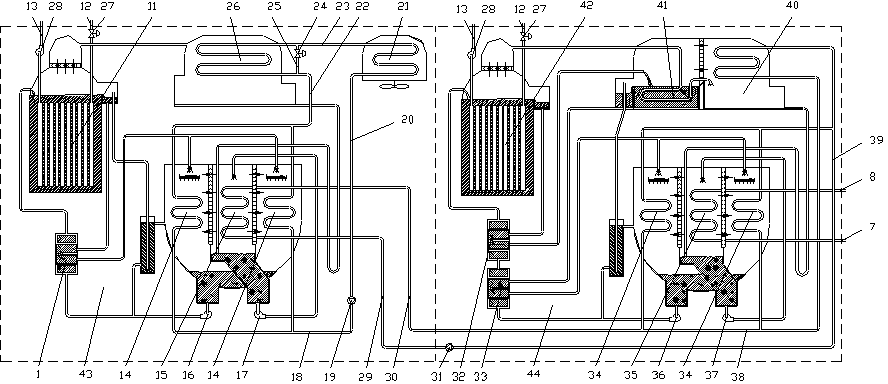

[0024] The present invention as figure 2 The refrigerating machine shown is composed of a single-effect high-temperature refrigeration group 43, an air cooler 21, a double-effect low-temperature refrigeration group 44, a control system (not shown in the figure), and pipelines and valves connecting various components. The formed cascade air-cooled flue gas single-double-effect compound lithium bromide absorption refrigerator. The single-effect high-temperature stage refrigeration unit 43 includes a solution heat exchanger 1, a high-temperature stage absorber 14, a high-temperature stage evaporator 15, a high-temperature stage solution pump 16, a high-temperature stage refrigerant pump 17, a high-temperature stage condenser 26 and a flue gas generator Device 11. The double-effect low-temperature refrigeration unit 44 includes a flue gas-type high-pressure generator 42, a low-pressure generator 41, a low-temperature condenser 40, a high-temperature heat exchanger 32, a low-temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com