Device for measuring pipe thermal displacement

A technology for measuring pipelines and thermal displacements, applied to measuring devices, optical devices, instruments, etc., can solve problems such as large errors, achieve long service life, low manufacturing costs, and easy installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below with reference to the drawings and embodiments.

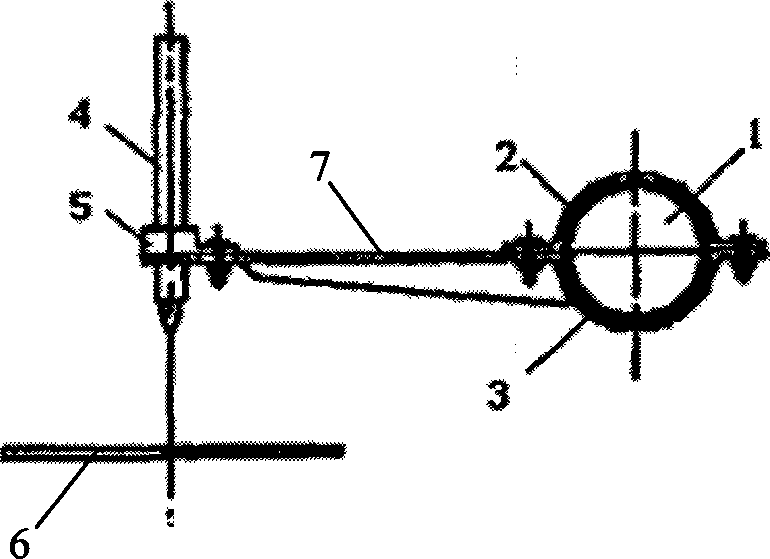

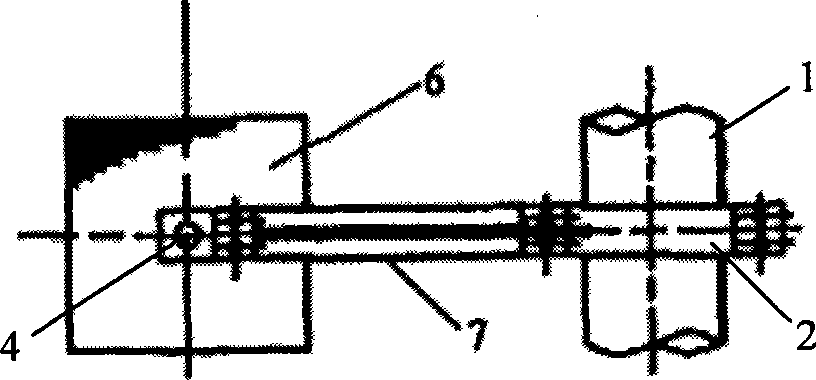

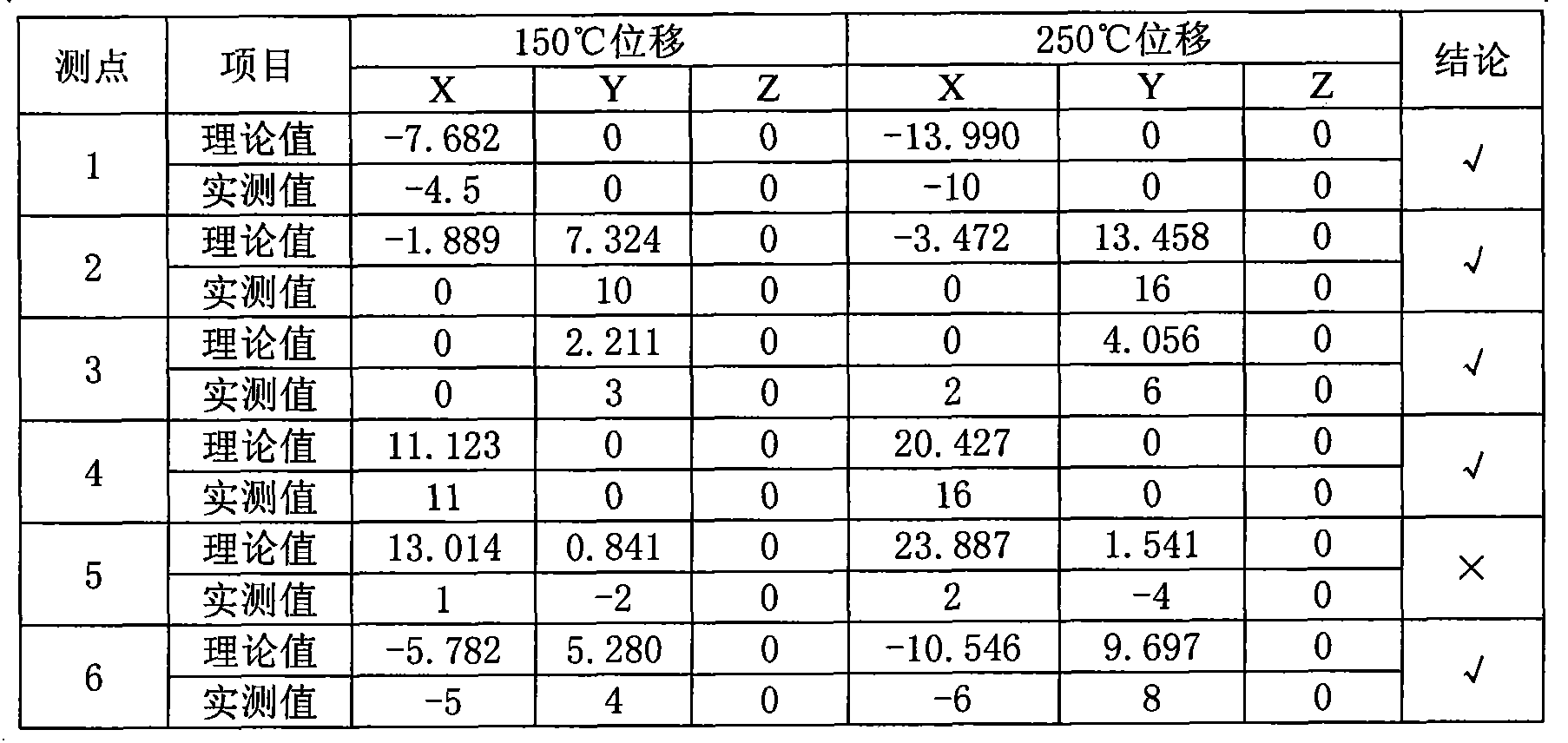

[0014] The pipeline thermal displacement measuring device provided by the present invention is aimed at the large thermal displacement of the CEFR main heat transfer system pipeline. It has a simple structure, easy installation and operation, low manufacturing cost, wide application range, long service life and no measuring range. Limited thermal displacement measuring device. Such as figure 1 , figure 2 As shown, the pipeline thermal displacement measuring device is mainly composed of upper and lower pipe clamps 2, 3, light pen pointer 4 and coordinate paper 6. The upper and lower pipe clamps 2, 3 are fixed on the pipe 1. The upper and lower pipe clamps 2, 3 are required to be fixed relative to the pipe 1 to ensure that no sliding or rotation occurs under working conditions; the light pen pointer 4 is installed on the pipe clamp through the light pen holder 5 The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com