On-line thermal imaging temperature monitoring method for power transformation device

A technology of substation equipment and thermal imaging, applied in the direction of electric radiation detectors, televisions, electrical components, etc., can solve the problems of limited operator installation height, single operation experience, and inability to fully observe most parts of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

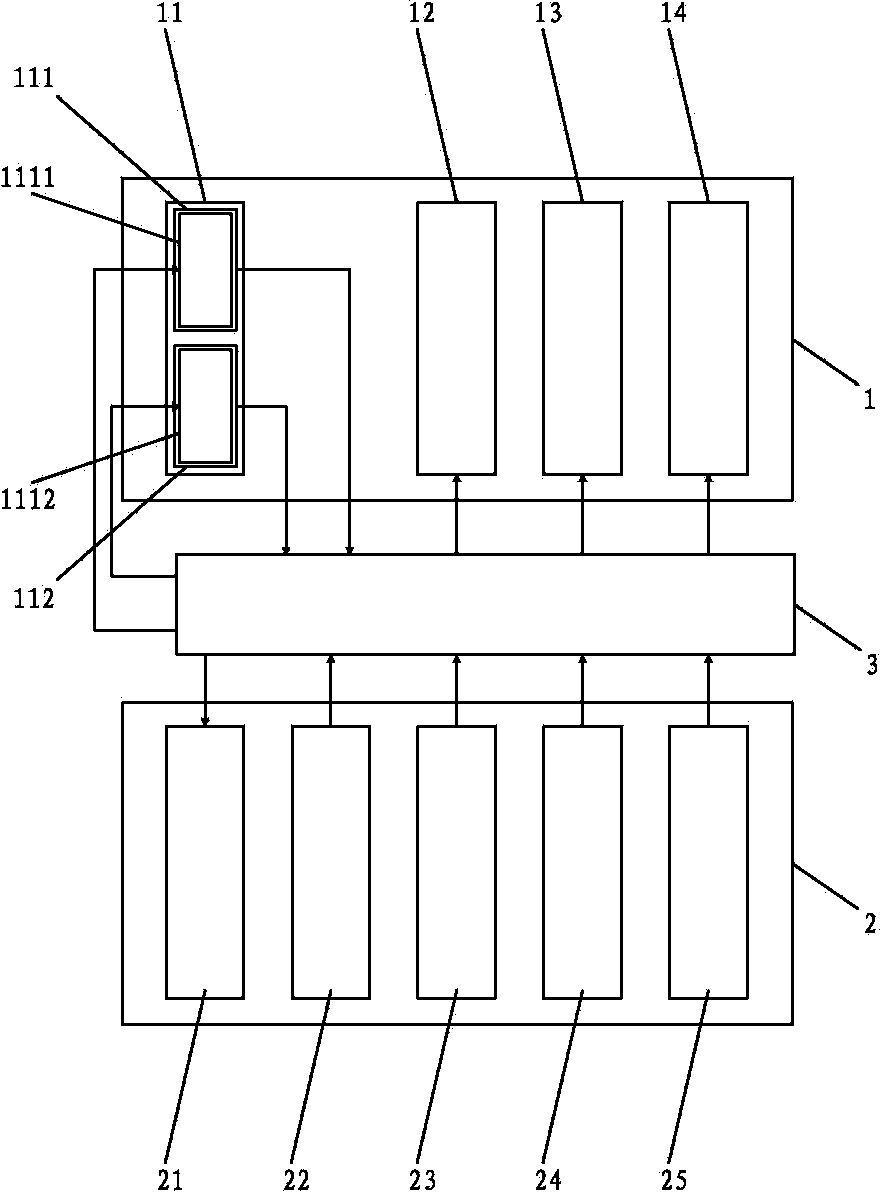

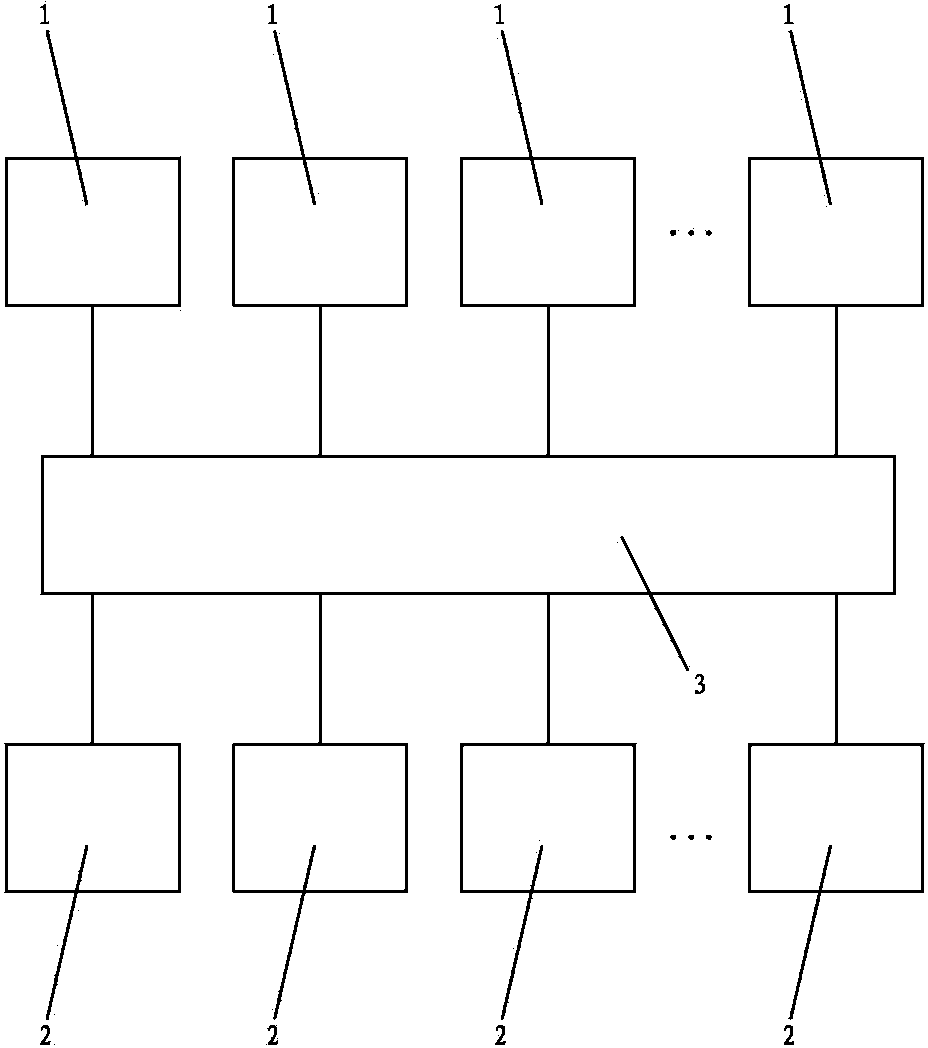

[0035] A method for on-line monitoring of thermal imaging temperature of substation equipment of the present invention, such as Figure 1-4 As shown, the end where the substation equipment is located is the field end 1, and the end where the monitoring customer is located is the client end 2.

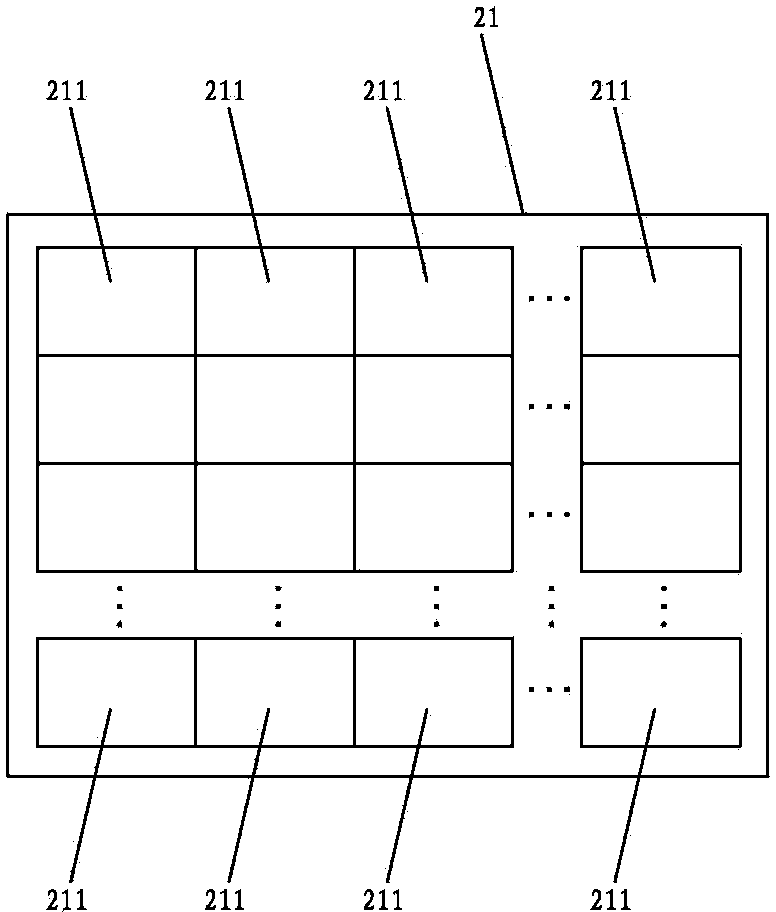

[0036]The present invention adopts a plurality of video signal collection devices 11 to carry out video signal collection to a plurality of field end monitoring points; Video signal collection device 11 comprises visible light video signal collection device 111 and infrared video signal collection device 112; Visible light video signal collection device 111 and infrared The video signal acquisition device 112 respectively collects the visible light video signal and the infrared video signal of the corresponding monitoring point, and transmits ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com