Method and device for water-sediment interface in-situ sampling and fixing

A sediment and interface technology, applied in the field of water environment research, can solve the problems of uncertainty in the depth of the collected sediment column and secondary sampling, and achieve the effects of reducing low-efficiency freezing, avoiding disturbance, and difficult to change the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

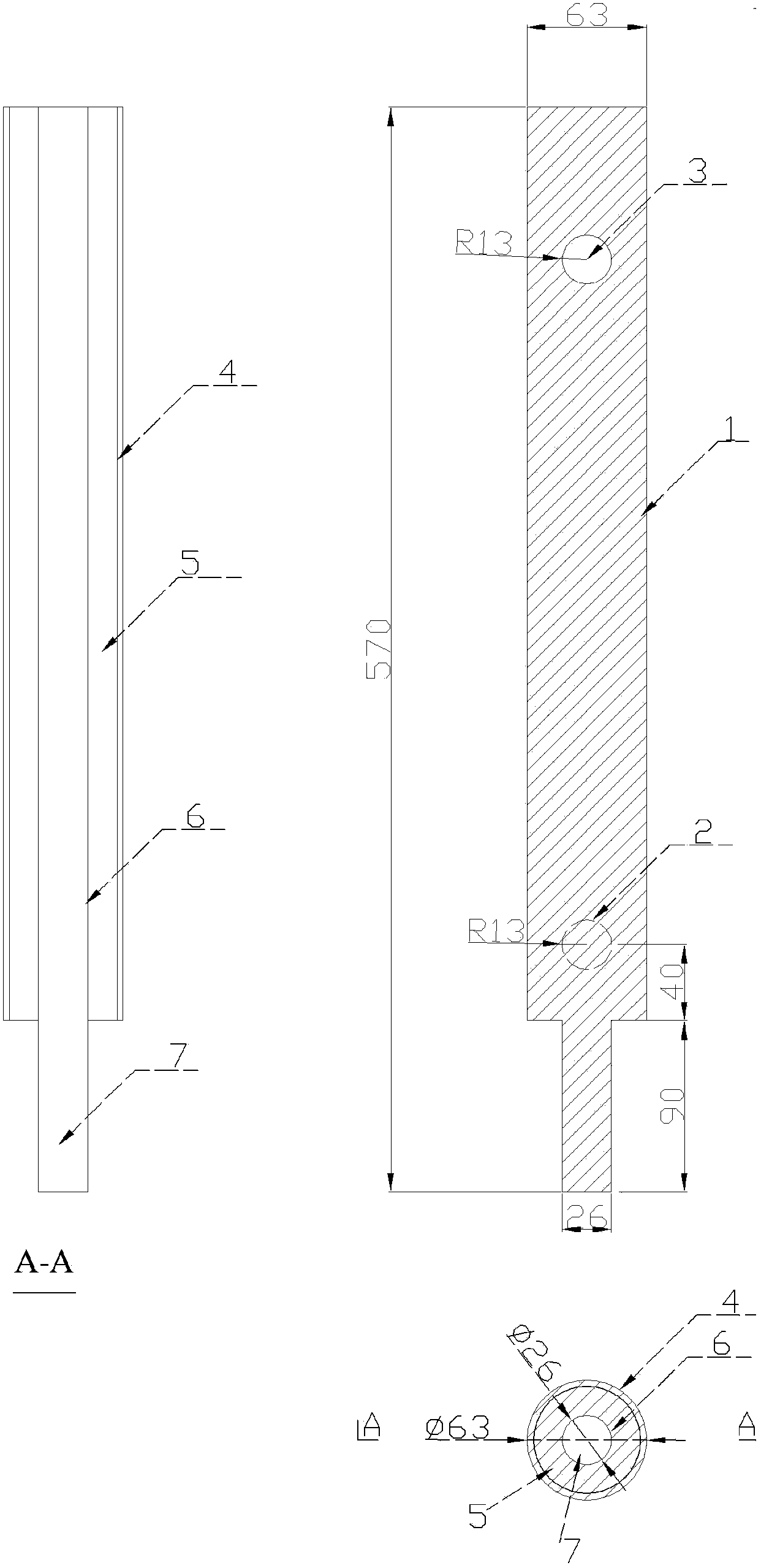

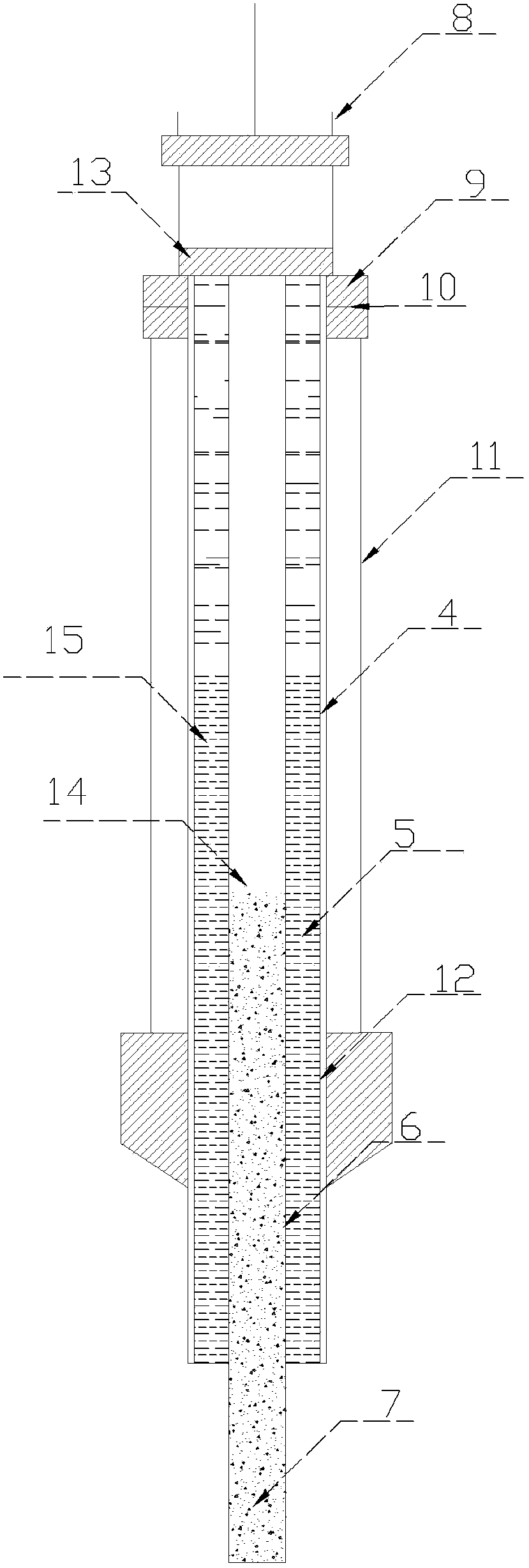

[0012] The design of the sampling tube of the deposition column: the iron tube (6) is nested with the heat-insulating plastic tube (4) to ensure the airtightness of the freezing chamber, and the liquid nitrogen input hole (2) is set at the lower end of the heat-insulating plastic tube (4), and the upper end Set the nitrogen discharge hole (3) to ensure the airtightness of the pipeline in the liquid nitrogen freezing system.

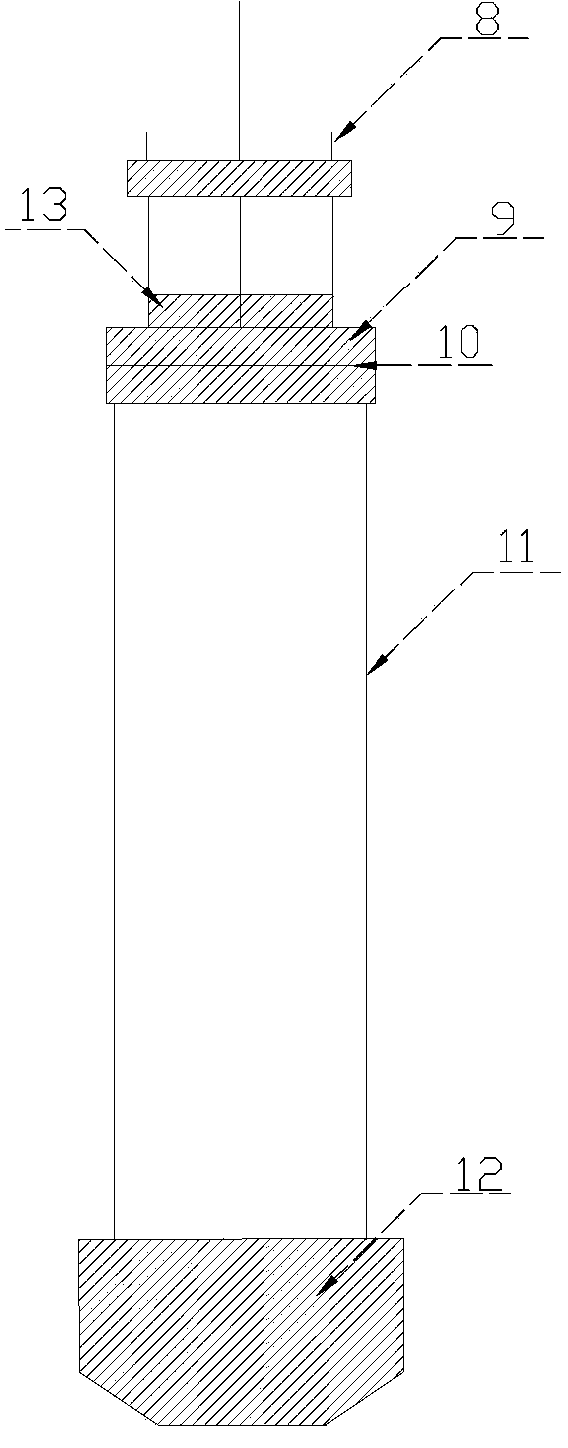

[0013] Assemble the sampling device: open the sampling tube locking lever (8), insert the sedimentation column sampling tube (1) into the self-gravity sedimentation column sampling bracket, close the sampling tube locking lever (8), squeeze the silicone ring (10 ), fix the sedimentation column sampling tube (1). Connect the liquid nitrogen input pipe of the self-pressurized liquid nitrogen tank to the liquid nitrogen input hole (2) of the deposition column sampling tube (1), and connect the spring check valve to the nitrogen gas discharge hole of the depo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com