Wet-type DCT clutch temperature control system based on fuzzy control and control method thereof

A temperature control system, a technology of fuzzy control, applied in the direction of temperature control using electric mode, general control system, control/regulation system, etc., can solve the problem of low temperature control accuracy of reaction delay clutch and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. The embodiments described with reference to the accompanying drawings are exemplary and are only used to explain the present invention, rather than to limit the present invention.

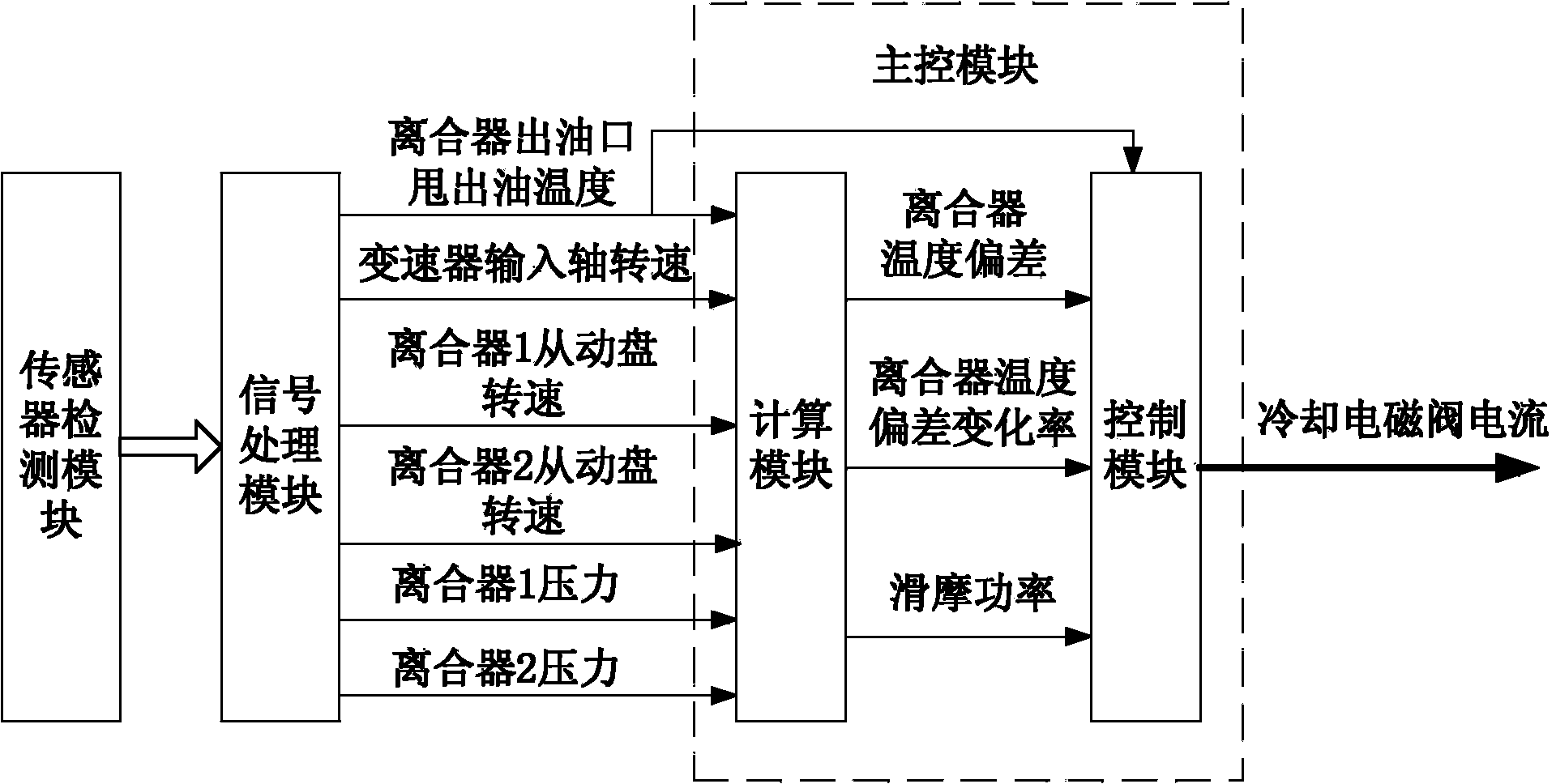

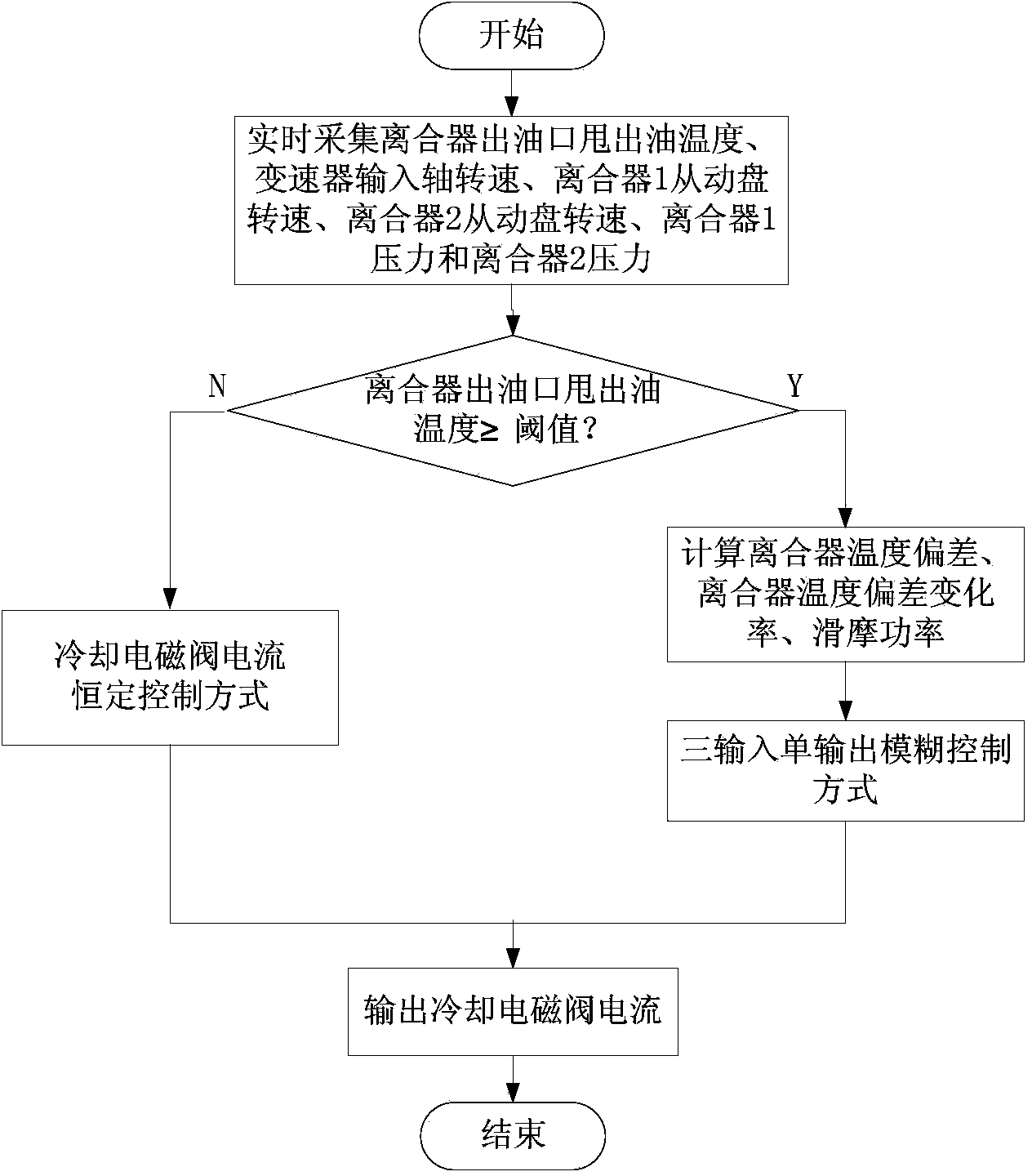

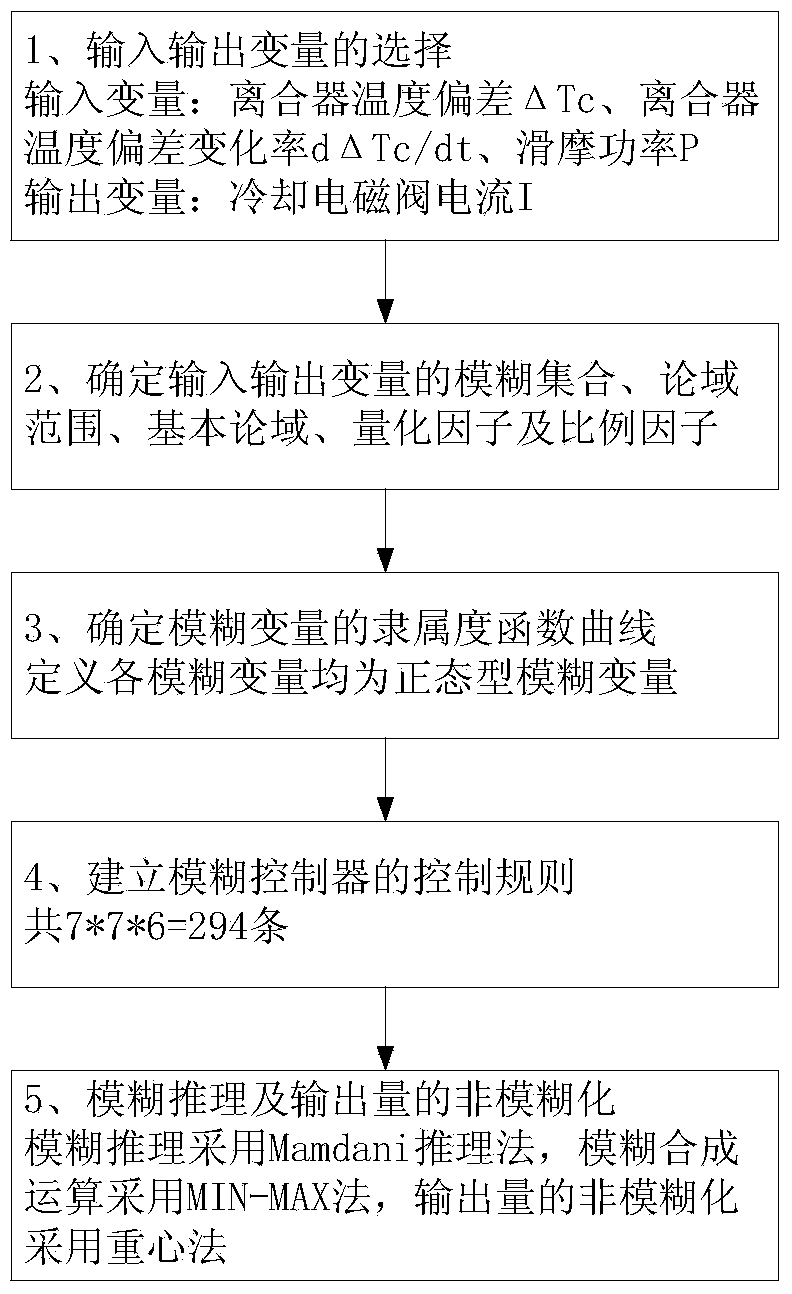

[0048] see figure 1 , the wet DCT clutch temperature control system based on fuzzy control is placed outside the automatic transmission electronic control unit (TCU), which includes a sensor detection module, a signal processing module, and a main control module. The main control module contains a calculation module and a control module. in,

[0049] The sensor detection module is used to obtain the oil temperature of the clutch oil outlet of the wet DCT, the speed of the transmission input shaft, the speed of the driven disc of clutch 1, the speed of the driven disc of clutch 2, the pressure of clutch 1 and the pressure of clutch 2; usually, The sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com