Array substrate, embedded touch screen and display device

An array substrate, touch drive technology, applied in the field of in-cell touch screens, display devices, and array substrates, can solve problems such as difficulty in achieving narrow borders, uneven loading, and uneven display, so as to improve picture quality and avoid unevenness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

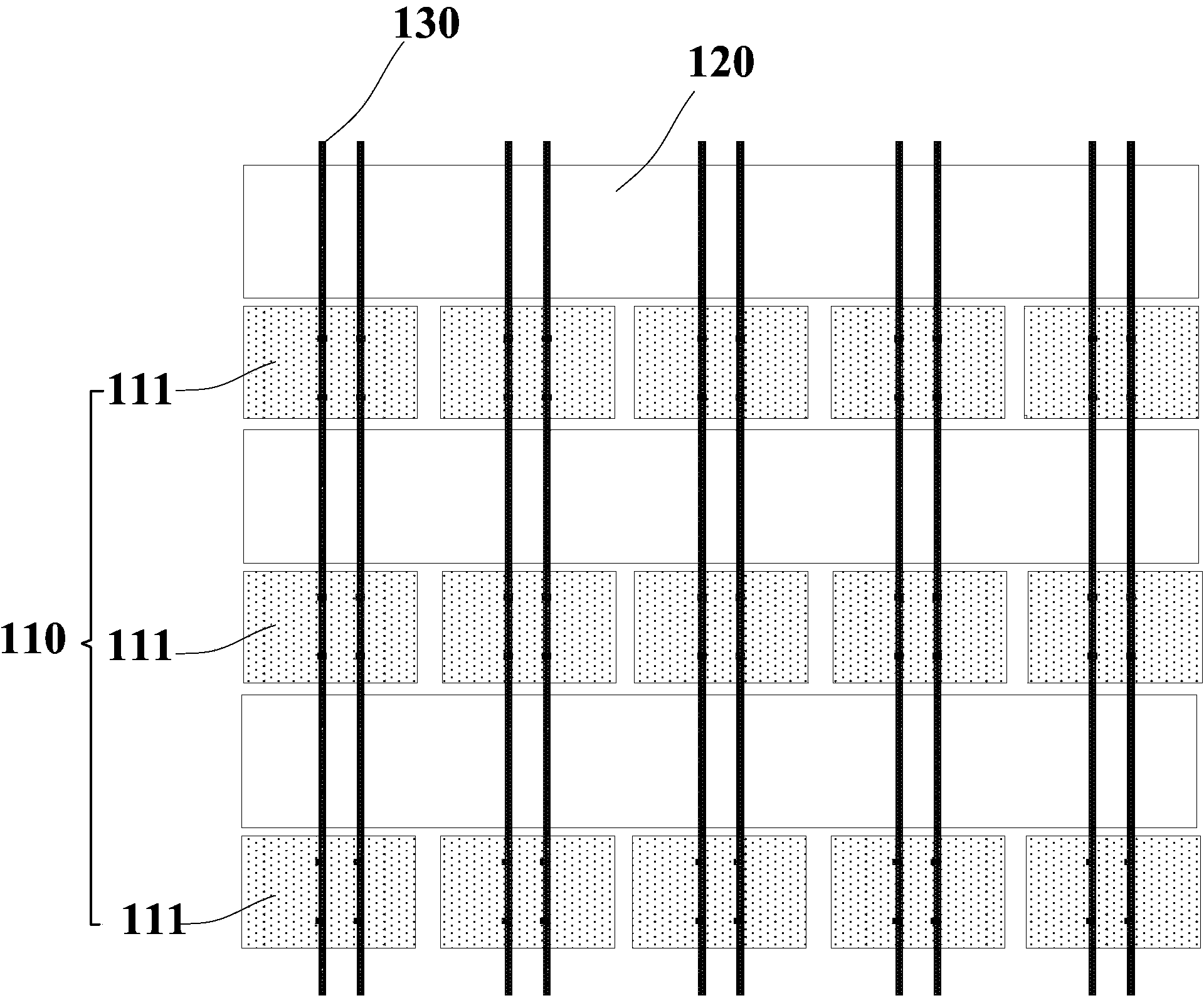

[0030] Please see image 3 , image 3 It is a schematic structural diagram of an array substrate according to an embodiment of the present invention. The common electrode layer of the array substrate includes a plurality of touch driving electrodes 110 and a plurality of common electrodes 120 insulated from each other. The touch driving electrodes 110 and the common electrodes 120 intersecting; the touch driving electrode 110 includes a plurality of touch driving sub-electrodes 111 arranged along the extending direction of the touch driving electrode 110, each of the touch driving sub-electrodes 111 is located in the adjacent between the common electrodes 120 .

[0031] In the embodiment of the present invention, the common electrode layer connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com