Thrust sliding bearing

A sliding bearing and thrust technology, used in sliding contact bearings, bearings, bearings in rotary motion, etc., can solve problems such as increased frictional resistance, achieve low friction performance, and achieve the effect of installation operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061]In the following, the present invention will be described in more detail with reference to preferred embodiments shown in the accompanying drawings. It should be noted that the present invention is not limited to these Examples.

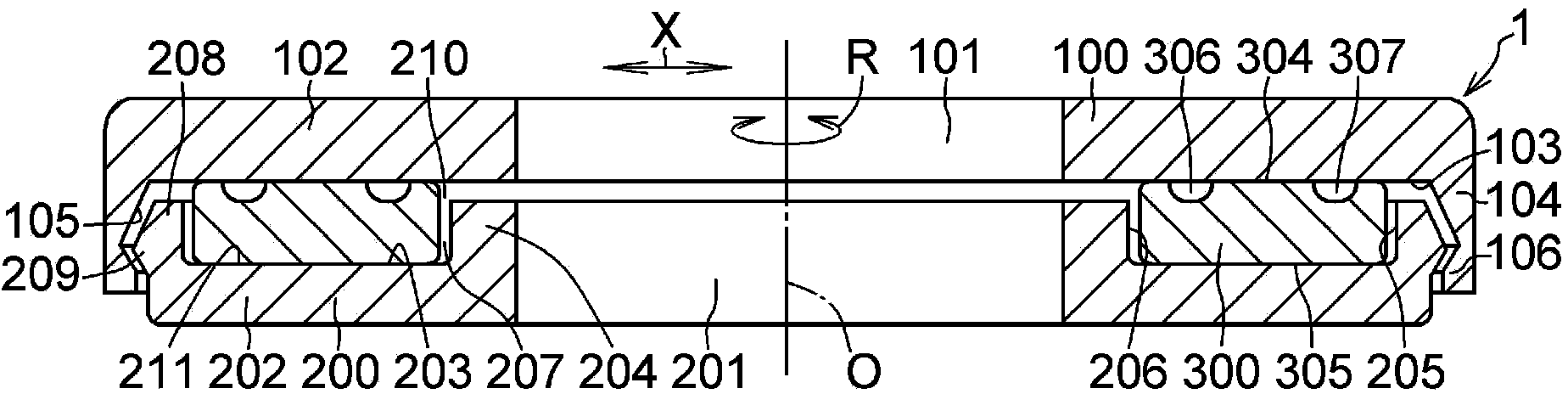

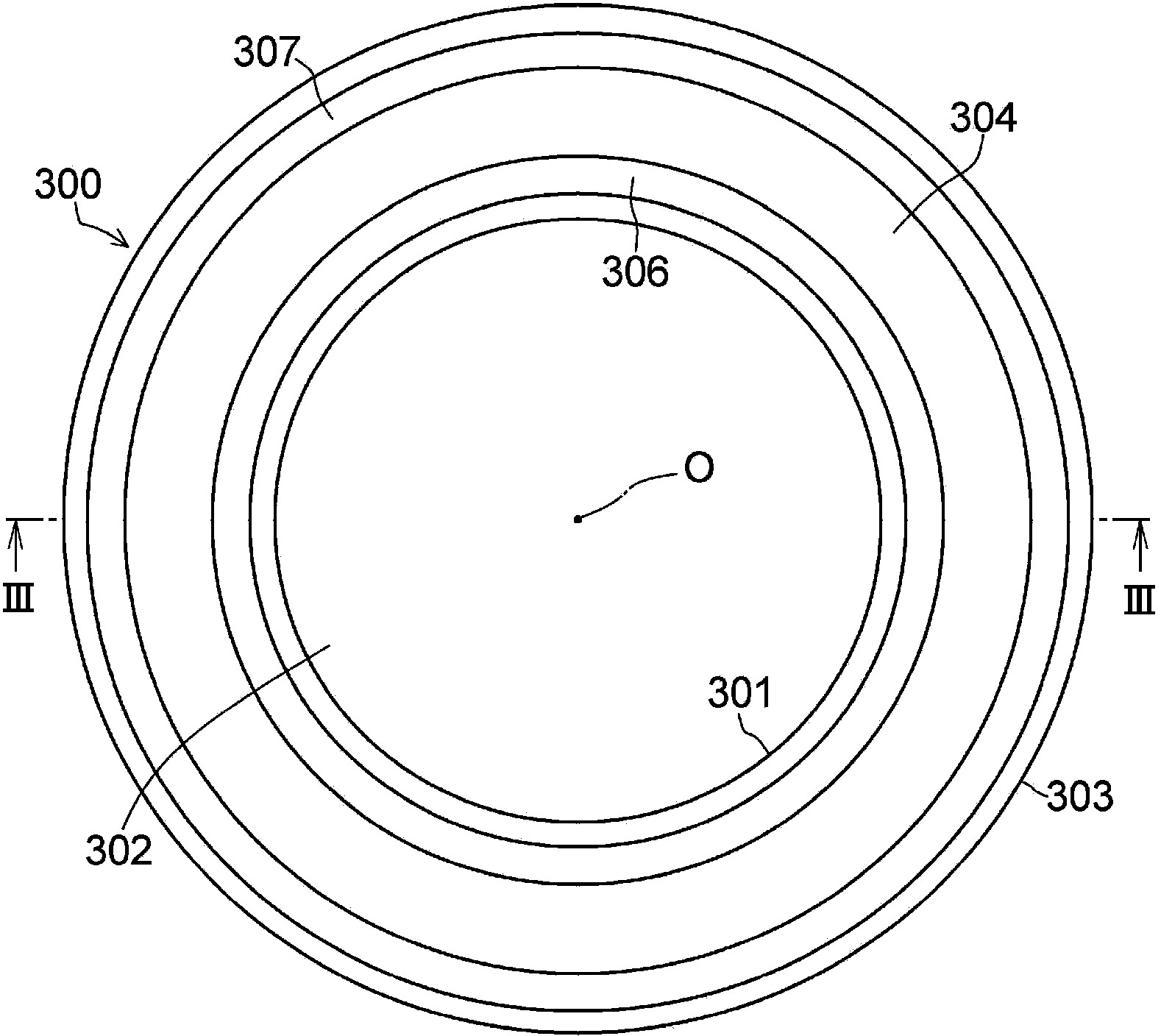

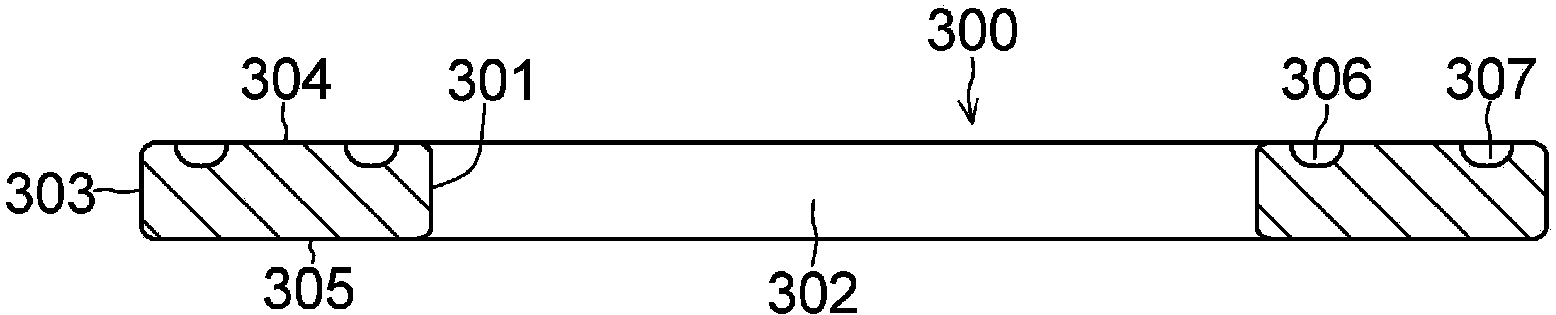

[0062] exist Figure 1 to Figure 5 , the thrust sliding bearing 1 according to the present embodiment includes an upper casing 100 made of synthetic resin, a lower casing 200 made of synthetic resin, and a thrust sliding bearing 300 made of synthetic resin provided between the upper casing 100 and the lower casing 200 .

[0063] The upper housing 100 includes: an upper annular flat portion 102 having a circular hole 101 at its central portion; a cylindrical engaging suspension portion 104 integrally formed on the cylindrical engaging suspension portion 104 on the outer periphery of the annular lower surface 103 of the upper annular flat portion 102 ;

[0064] The lower shell 200 stacked on the upper shell 100 so as to be able to rotate aroun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com