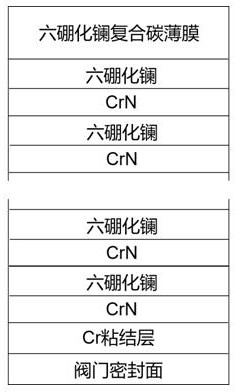

Corrosion-resistant and wear-resistant lanthanum hexaboride composite carbon film and deposition method thereof

A technology of lanthanum hexaboride and composite carbon, which is applied in ion implantation plating, metal material coating process, coating and other directions, can solve problems such as safety hazards, prolong service life, improve impact resistance, and improve strength and toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

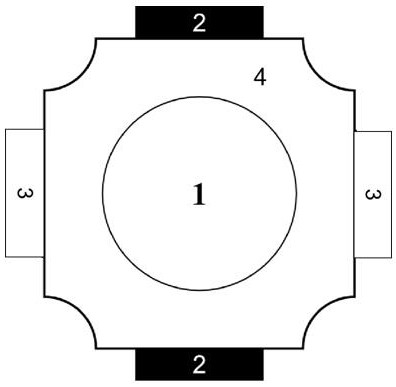

[0035] (1) Choose 316L stainless steel ball valve, and clean the plated valve body with hydrocarbon to remove oil stains, rust spots, etc.;

[0036] (2) Load the valve body to be plated on the rotating tooling frame in the center of the coating vacuum chamber, and keep it rotatable by 360°;

[0037] (3) Vacuum the coating vacuum chamber to 10 -4 Pa, turn on the rotary tooling and let it rotate at a speed of 2 rpm; turn on the high-voltage pulse power supply, feed in argon and hydrogen (air flow ratio 1:1), adjust the air pressure to 3 Pa, bias to 3000 V, frequency to 500 Hz, Duty cycle 5%, cleaning for 30 minutes;

[0038] (4) Turn off the hydrogen and high-voltage pulse power supply, keep the argon gas at 1Pa, turn on the DC pulse power supply, adjust the bias voltage to 650V, the duty cycle to 50%, and the frequency to 20 KHz; turn on the Cr target, control the current to 15A, the pulse frequency to 20 Hz, and the duty cycle Ratio of 40%, deposition for 30 minutes;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com