Surface polishing machine

A technology for surface polishing and polishing discs, applied in the field of polishing machines, can solve problems such as inconvenience and hidden dangers to operator safety, and achieve the effects of simple operation, improved polishing efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

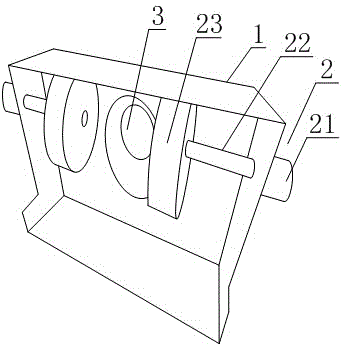

[0020] Such as figure 1 A surface polishing machine is shown, which includes an operation box 1 and two groups of polishing devices 2 fixed on the operation box 1. The operation box 1 is provided with an air exhaust port 3, and the air exhaust port 3 is located in the two groups Between the polishing devices 2 , the air exhaust port 3 is provided with an air exhaust device outside the operation box 1 . The draft device can be set as an exhaust fan or a draft device.

[0021] The polishing device 2 includes a driving device 21 , a connecting rod 22 fixed on the driving device 21 and a polishing disc 23 fixed on the connecting rod 22 .

[0022] The air intake 3 is located between two polishing discs 23 .

[0023] The drive device 21 is an electric motor.

[0024] The driving device 21 is respectively fixed on two corresponding surfaces of the operation box 1 , and the connecting rod 22 and the polishing disc 23 are both located in the operation box 1 .

[0025] The length of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com