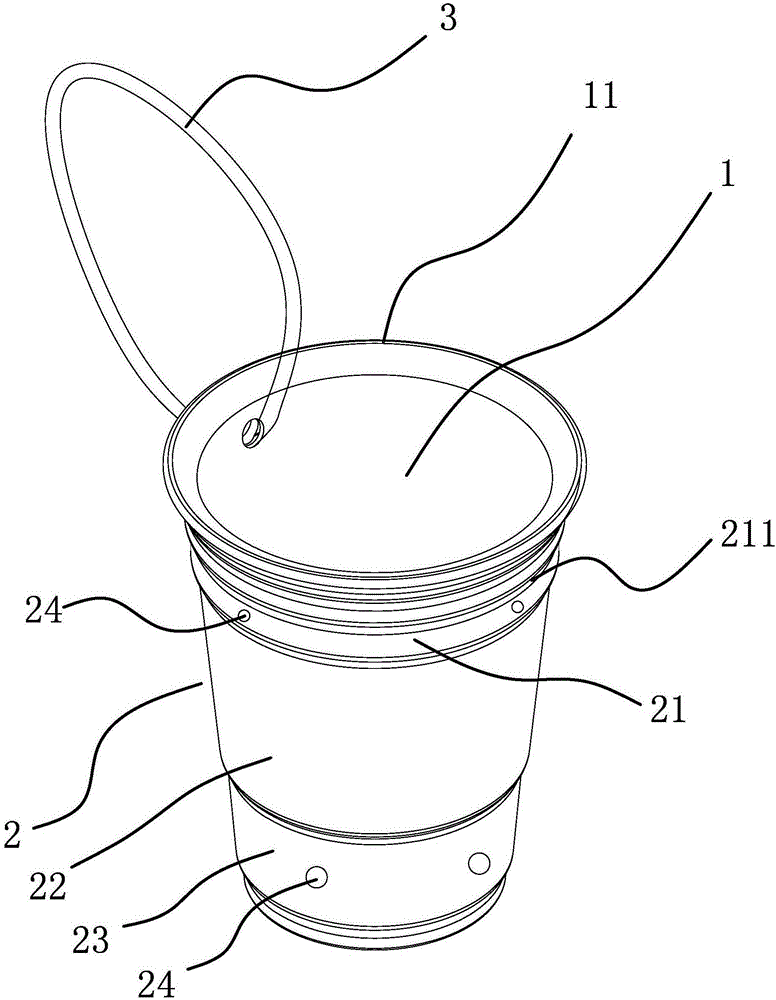

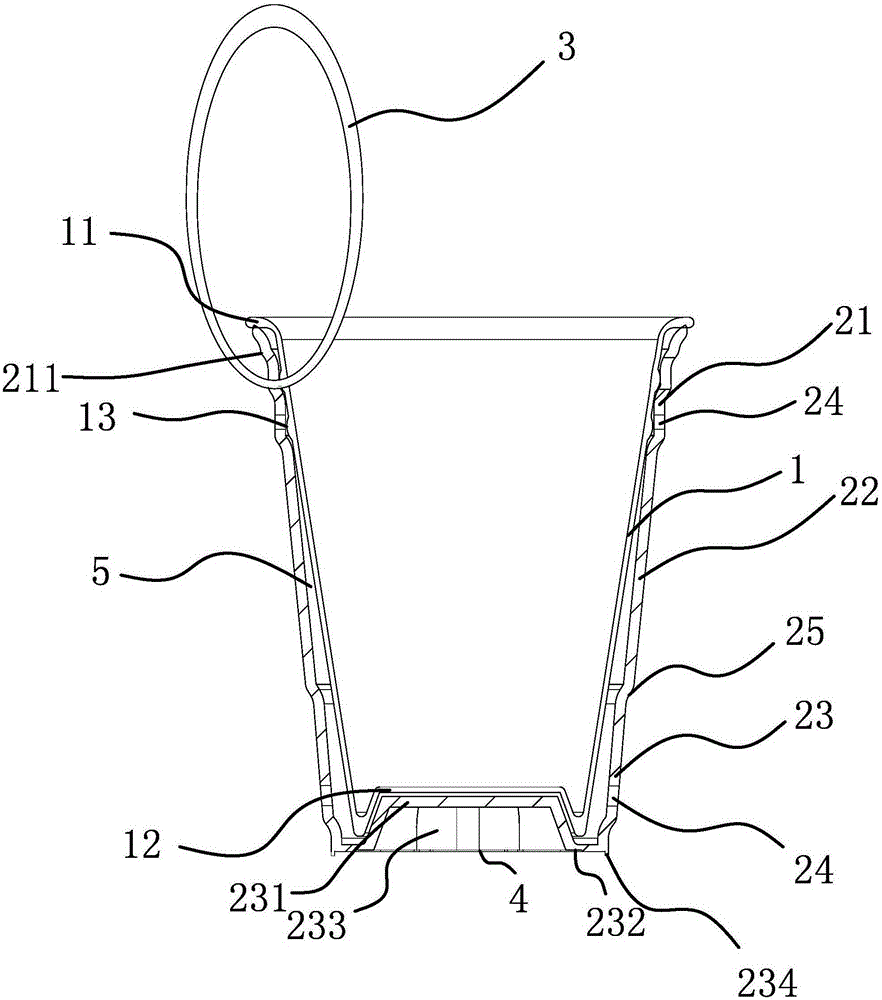

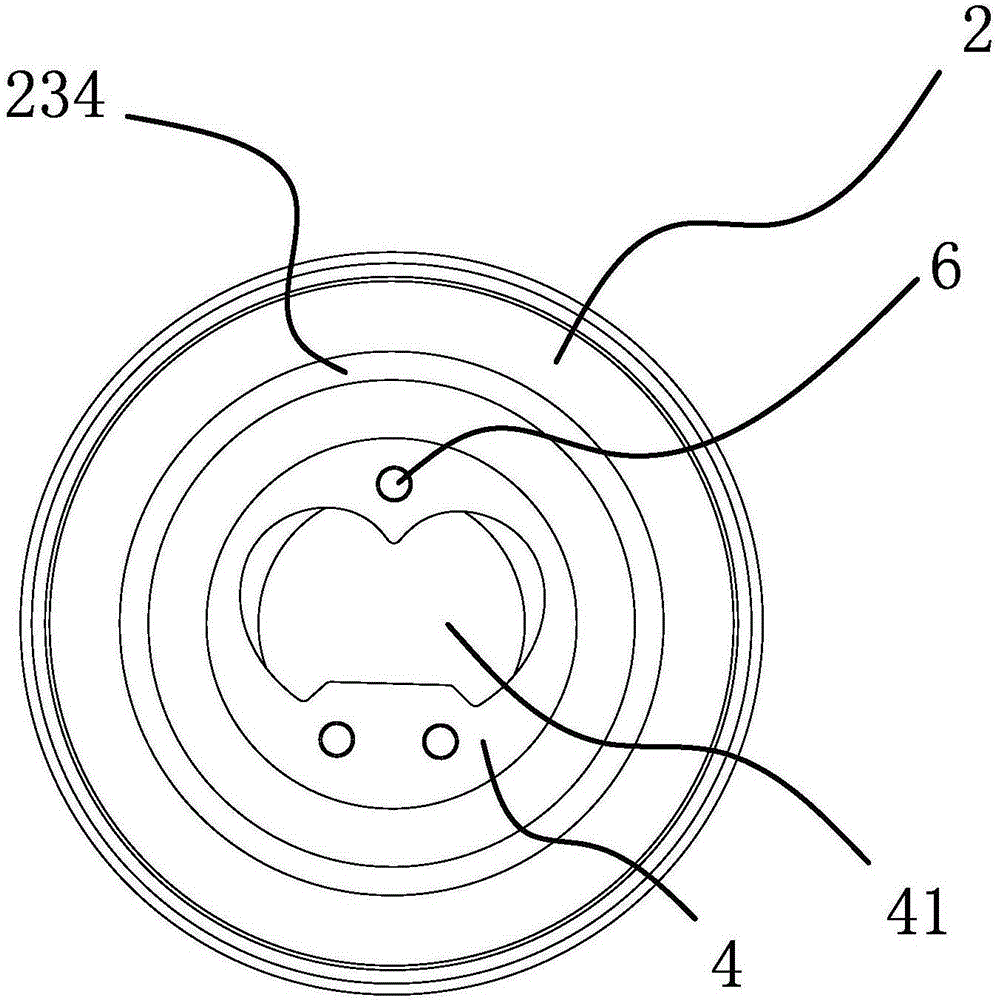

A double-layer lanyard cup with a bottle opener

A bottle opener and double-layer technology, applied in the field of double-layer lanyard cups and cups, can solve the problems of affecting the drinking effect, user's hand discomfort, and difficulty in placing, and achieve good dimensional stability and excellent surface. The effect of finish, improving toughening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] S1. Weigh the raw materials of the liner cup composite material according to the following components and their mass percentages: homopolymer PP: 20%, copolymer PP: 30%, POE: 15%, nano-silica: 6%, glass fiber: 16.2 %, antioxidant: 0.8%, talcum powder: 12%, while heating the barrel in the high-speed injection molding machine to 250°C, then mix the weighed raw materials evenly and add them to the barrel, and heat to a molten state; wherein, The average particle diameter of described nano silicon dioxide is 15nm; The length of described glass fiber is 20mm;

[0047] S2. Inject the raw materials in the molten state into the mold of the liner cup at a temperature of 80°C through the nozzle of the hot runner at 250°C, pressurize, cool and form, and open the mold to obtain the liner cup. Among them, the injection pressure is 150MPa, the holding pressure is 120MPa, the holding time is 10s, and the cooling time is 50s.

Embodiment 2

[0049] S1. Weigh the raw materials of the liner cup composite material according to the following components and their mass percentages: homopolymer PP: 25%, copolymer PP: 30%, POE: 12%, nano-silica: 7%, glass fiber: 15% %, antioxidant: 0.5%, talcum powder: 10.5%, while heating the barrel in the high-speed injection molding machine to 210°C, then mix the weighed raw materials evenly and add them to the barrel, and heat to a molten state; wherein, The average particle diameter of nanometer silicon dioxide is 10nm; The length of described glass fiber is 10mm;

[0050] S2. Inject the raw materials in the molten state into the mold of the liner cup at a temperature of 60°C through the nozzle of the hot runner at 220°C, pressurize, cool and form, and open the mold to obtain the liner cup. Among them, the injection pressure is 130MPa, the holding pressure is 110MPa, the holding time is 5s, and the cooling time is 30s.

Embodiment 3

[0052] S1. Weigh the raw materials of the liner cup composite material according to the following components and their mass percentages: homopolymer PP: 30%, copolymer PP: 25%, POE: 13%, nano-silica: 6%, glass fiber: 15% %, antioxidant: 1%, talcum powder: 10%, while heating the barrel in the high-speed injection molding machine to 280°C, then mix the weighed raw materials evenly and add them to the barrel, and heat to a molten state; wherein, The average particle diameter of nanometer silicon dioxide is 20nm; The length of described glass fiber is 30mm;

[0053] S2. Inject the raw materials in the molten state into the mold of the liner cup at a temperature of 60-100°C through the nozzle of the hot runner at 280° C., pressurize, cool and form, and open the mold to obtain the liner cup. Among them, the injection pressure is 170MPa, the holding pressure is 150MPa, the holding time is 20s, and the cooling time is 60s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap