Glass pelletizing machine

A glass granule and the other side technology, applied in the field of granulation equipment, can solve the problems of spraying blind area and poor drying effect, and achieve the effect of meeting the conveying needs, good drying effect and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below by means of specific embodiments:

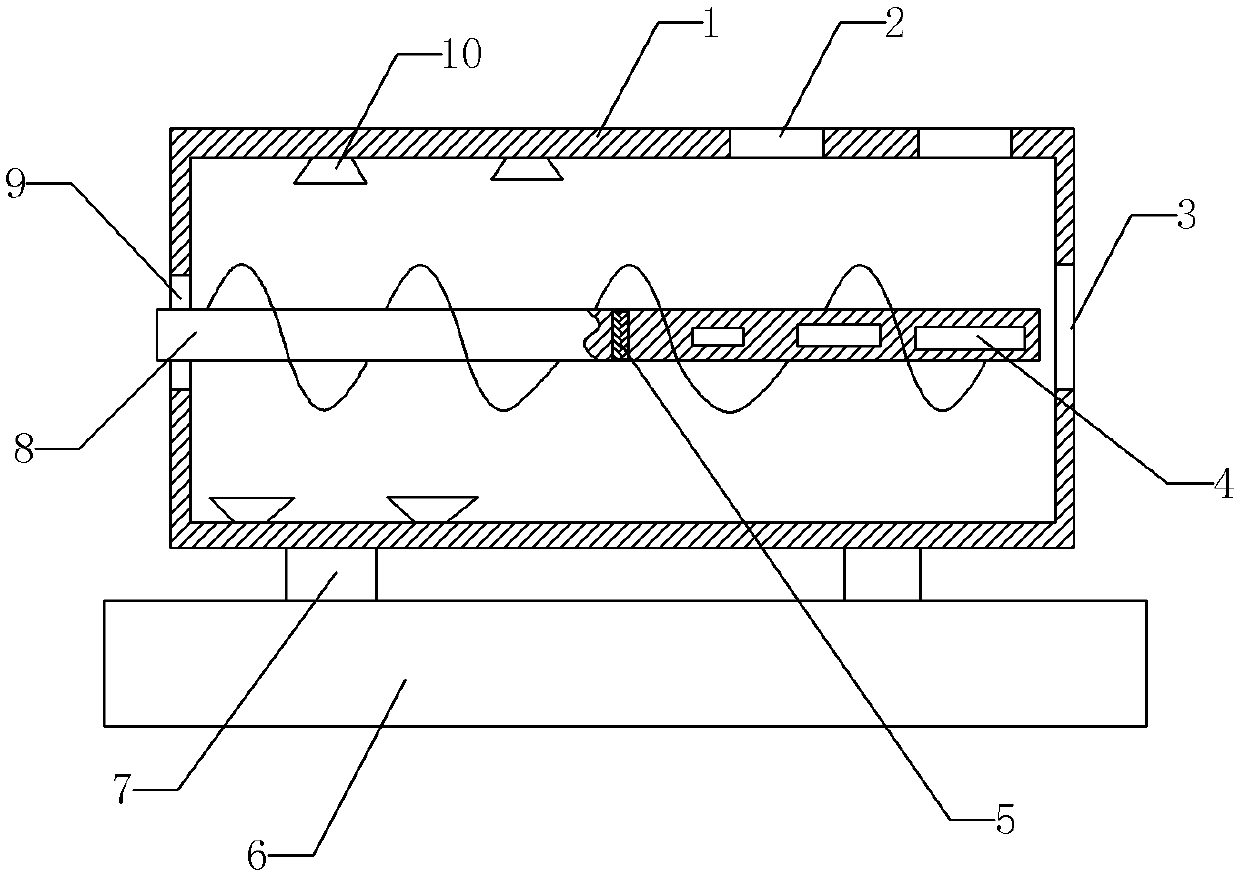

[0011] The reference signs in the drawings of the description include: drum 1, air inlet 2, ball forming outlet 3, cavity 4, heat insulation layer 5, base 6, support feet 7, screw conveyor 8, powder inlet 9, nozzle 10 .

[0012] The embodiment is basically as attached figure 1 As shown: in the glass granulating machine of this embodiment, the drum 1 is driven by power to rotate during work, and two supporting feet 7 are arranged symmetrically along the axial direction of the drum 1 at the lower part of the drum 1, and each supporting foot 7 is in the shape of U-shaped, the outer circle of the drum 1 is supported in the U-shaped support groove formed by the supporting feet 7, and the lower parts of the two supporting feet 7 are fixed on the base 6.

[0013] In this embodiment, one side of the drum 1 is provided with a powder inlet 9, and the other side of the drum 1 is p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap