High-intensity focused ultrasound ice crushing and removing system

A focused ultrasound, high-intensity technology, used in snow surface cleaning, construction, cleaning methods, etc., can solve problems such as serious road hazards, ice and snow residues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

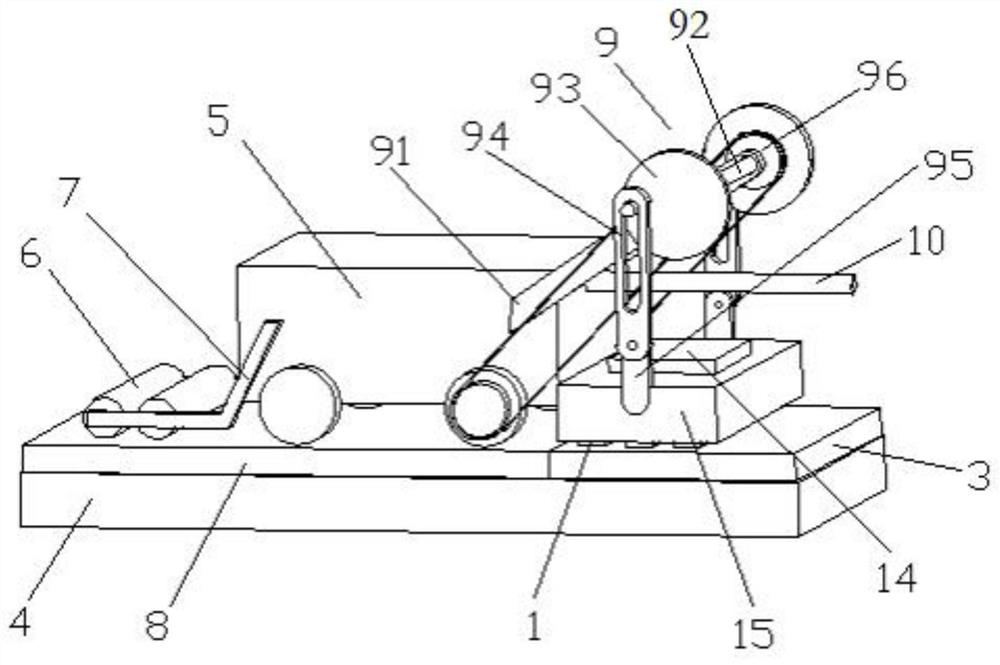

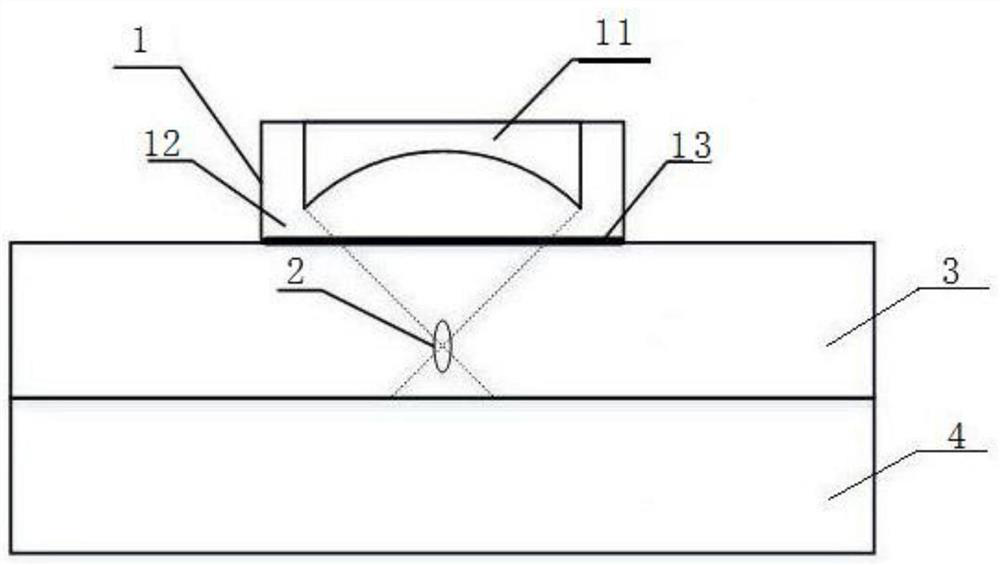

[0024] like Figure 1-2 As shown, the high-intensity focused ultrasonic ice crushing and deicing system includes a box body 5, a walking mechanism 9, an ultrasonic peeling roller 6 and an ice crushing device. The traction bar 7 is connected with the ultrasonic peeling roller 6, and the bottom of the box body 5 is equipped with a roller, at least one set of corresponding rollers is connected by a rotating shaft spline, and a driving wheel is installed on the rotating shaft, and the rotating shaft is connected with the driving wheel key , the box 5 is connected to the ice crushing device through the walking mechanism 9, the ice crushing device includes a focused ultrasound control box 14, a focusing probe fixing seat 15, and a sealing box 1, and the bottom of the focusing probe fixing seat 15 is fixedly connected There are a plurality of sealing boxes 1, and the plurality of sealing boxes 1 are evenly distributed on the bottom of the focusing probe fixing seat 15.

[0025] The ...

Embodiment 2

[0040] like Figure 1-2 As shown, the high-intensity focused ultrasonic ice crushing and deicing system includes a box body 5, a walking mechanism 9, an ultrasonic peeling roller 6 and an ice crushing device. The draw bar 7 is connected with the ultrasonic peeling roller 6, and the bottom of the box body 5 is equipped with a roller, and the rollers are splined through a rotating shaft, and a driving wheel is installed on the rotating shaft, and the rotating shaft is connected with the driving wheel key, and the casing 5. The walking mechanism 9 is connected to the ice crushing device. The ice crushing device includes a focused ultrasound control box 14, a focusing probe fixing seat 15, and a sealing box 1. The bottom of the focusing probe fixing seat 15 is fixedly connected with a plurality of sealing boxes 1. A plurality of sealed boxes 1 are evenly distributed on the bottom of the focusing probe fixing seat 15 .

[0041] The high-intensity focused ultrasonic probe 11 is ins...

Embodiment 3

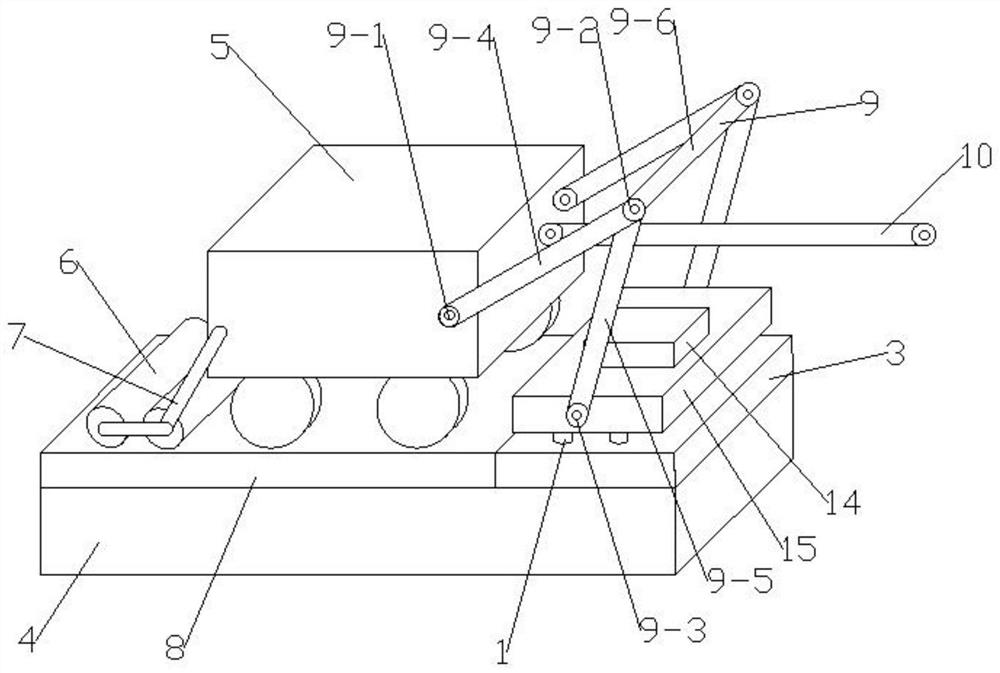

[0052] After research, the researchers have found that the walking mechanism 9 provided by the present invention, on the basis of the above-mentioned embodiment 1, can also make the following optional other structural solutions, which are specifically described as follows:

[0053] like image 3 As shown, the walking mechanism 9 includes a first motor 9-1 and a first arm 9-4, the first motor 9-1 is installed on the box 5, and the first arm 9-4 Connected to both sides of the box body 5, the first moment arm 9-4 is connected with a connecting rod 9-6, the first moment arm 9-4 is connected to the second moment arm 9-5, the first moment arm 9- A second motor 9-2 is installed between 4 and the second arm 9-5, a third motor 9-3 is installed at the bottom of the second arm 9-5, and the second arm 9-5 is connected with the ice crushing device , the first motor 9-1 controls the first arm 9-4, the second motor 9-2 controls the second arm 9-5, the third motor 9-3 controls the ice crushi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap