Rectangular coordinate slag-off robot for aluminum pig casting machine

A Cartesian coordinate, casting machine technology, applied in foundry equipment, mechanical cleaning, manufacturing tools, etc., can solve the problems of burns, casualties, and high operating costs in the working environment, achieving significant social benefits, coherent and coordinated actions, and eliminating potential safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

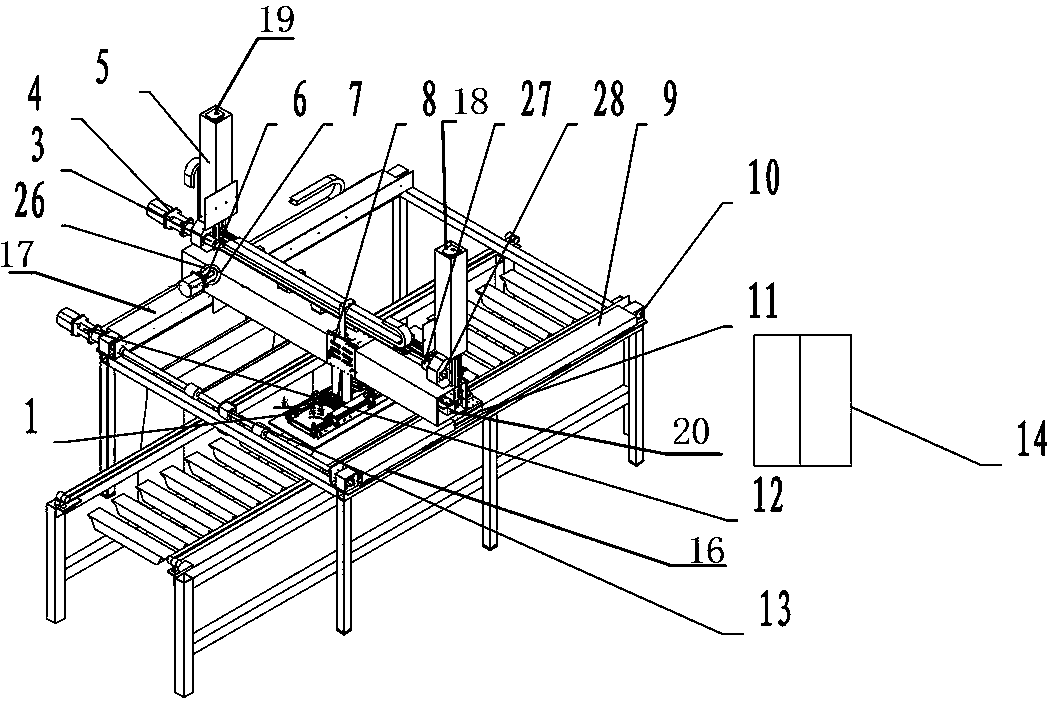

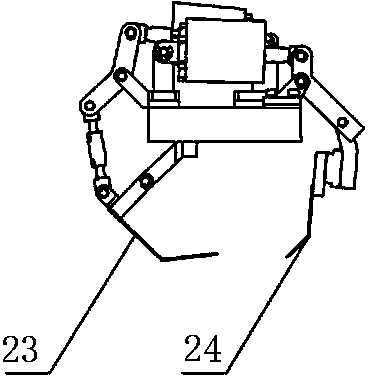

[0015] Cartesian coordinate slag removal robot for aluminum ingot casting machine, including main frame 15, horizontal and vertical Y-axis assembly, horizontal X-axis assembly, vertical and vertical Z-axis assembly and pneumatic slag removal manipulator assembly;

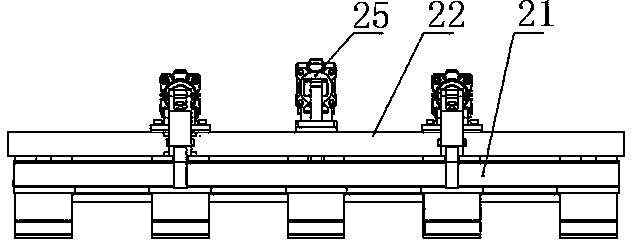

[0016] The horizontal and longitudinal Y-axis assembly includes Y-axis linear guide rail I16, Y-axis linear guide rail II17, Y-axis motor reducer 12, Y-axis synchronous chain 9, Y-axis sprocket 10, and Y-axis slider 11; The linear guide rail Ⅰ16 and the Y-axis linear guide rail Ⅱ17 are fixed on the main frame 15 by bolts, and the Y-axis motor reducer 12 is connected with the Y-axis linear guide rail Ⅰ16 and the Y-axis linear guide rail Ⅱ17 through the Y-axis coupling 13. Ⅰ16, Y-axis linear guide rail Ⅱ17 respectively install Y-axis synchronous chain 9, Y-axis sprocket 10, and Y-axis slider 11;

[0017] The horizontal X-axis assembly includes an X-axis linear guide rail, including an X-axis linear guide rail 20, an X...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com