Water spraying and slag removing mechanism of laser pipe cutting machine

A technology of pipe cutting machine and slag remover, which is applied to laser welding equipment, tubular objects, applications, etc., can solve the problems of dust particle splashing, environmental pollution, occupational injury of operators, etc., and achieves reduction of labor intensity, energy saving, environmental protection, noise, The effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

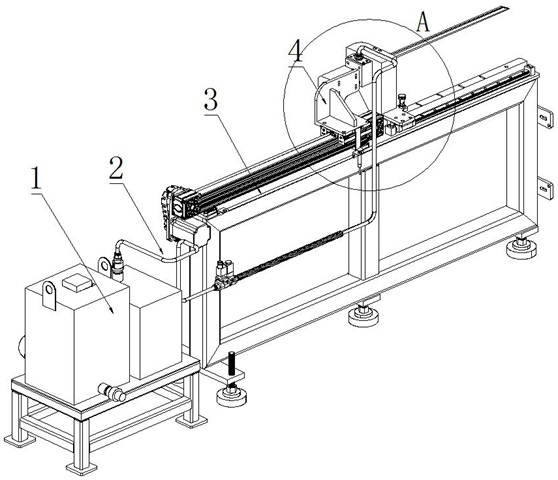

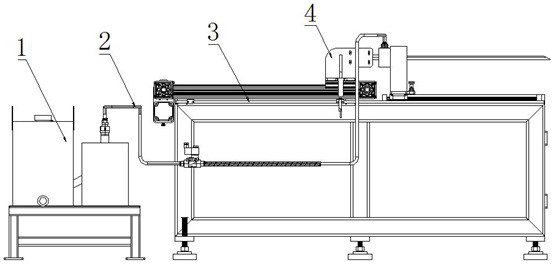

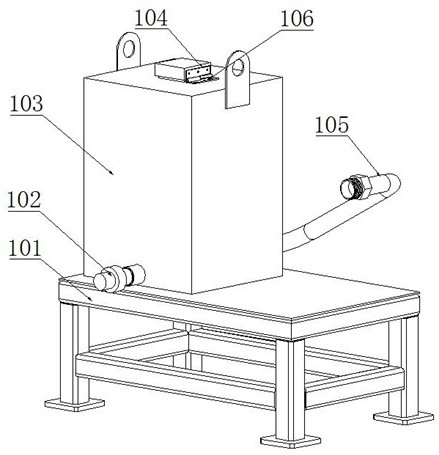

[0037] The present application will be further described in detail below in conjunction with the accompanying drawings. refer to Figure 1-8 , the present application discloses a water spraying and slag removing mechanism for a laser pipe cutting machine, which includes a water supply device 1, a water spray generating device 2, a slag removing water spray body 3 and a slag removing device 4, and the water supply device 1 is sequentially connected to a spraying machine. The water generating device 2 and the slag removing device 4, the water spray generating device 2 includes an atomizing nozzle 206, the atomizing nozzle 206 is installed on the slag removing device 4, and the slag removing device 4 includes Copper pipe 404, the top of the copper pipe 404 is provided with a material receiving tank, and the atomizing nozzle 206 is arranged towards the direction of the material receiving tank; The fuselage 3 is installed on the laser tube cutting machine.

[0038] like image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com