Floating Plug Inspection Gate

An overhaul gate and floating plug technology, applied in water conservancy engineering, marine engineering, coastline protection, etc., can solve the problems of difficult construction, inability to arrange, and large investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

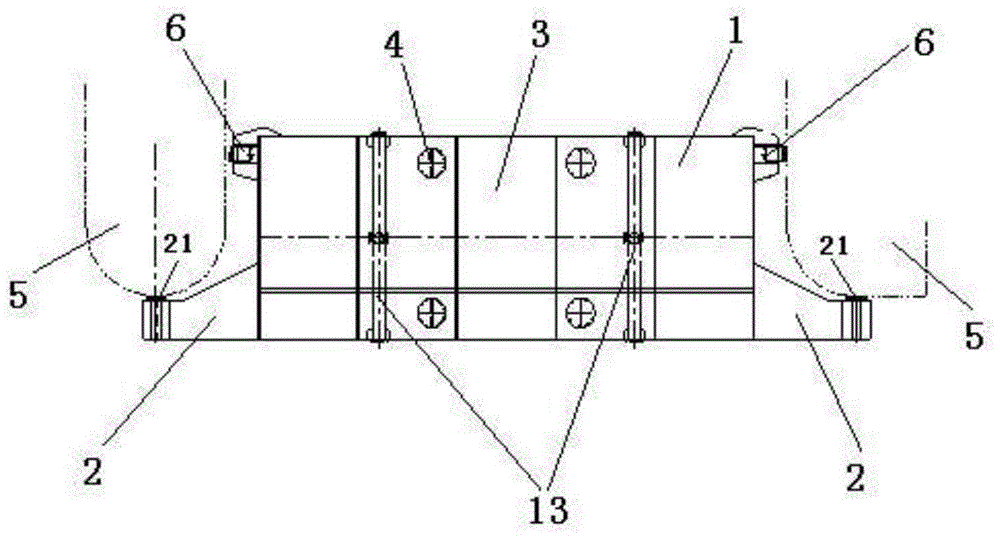

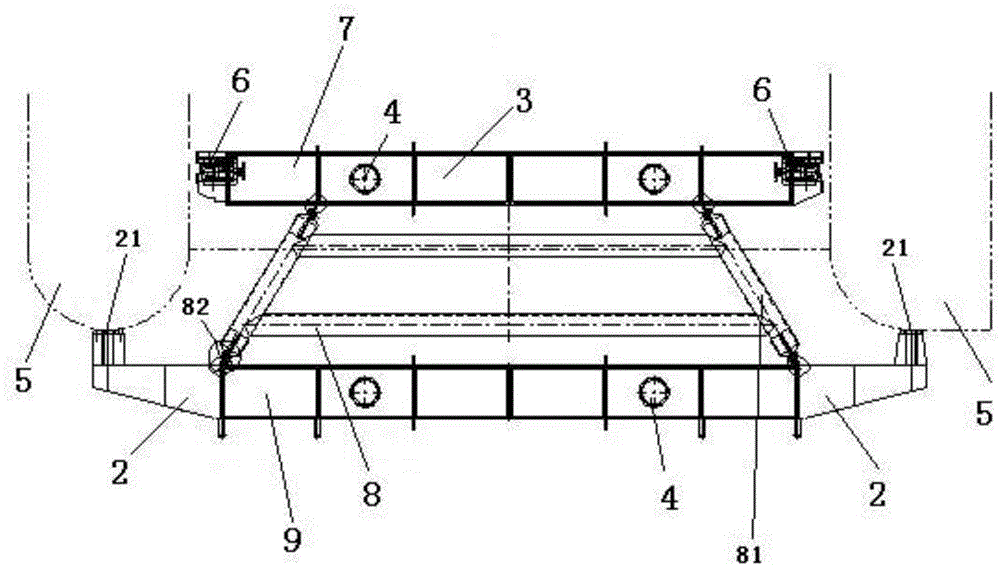

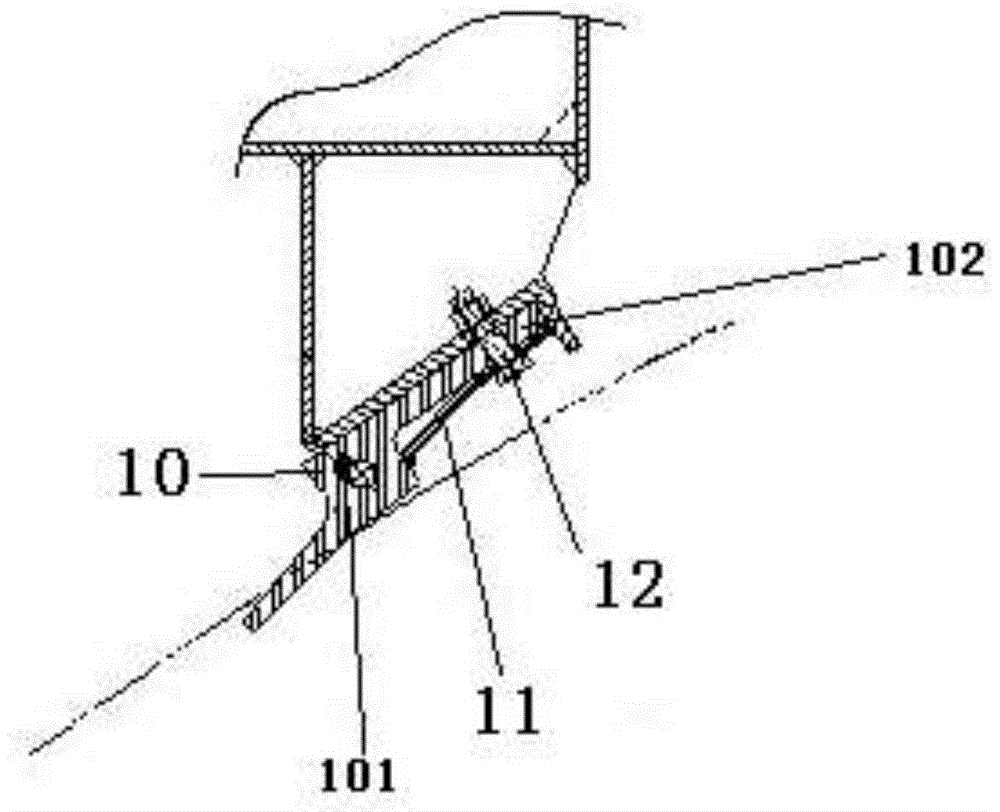

[0023] Such as figure 2 As shown, the second embodiment of the present invention is a combined floating plug maintenance gate, including a water-retaining floating body 7 , a supporting floating body 9 , a connecting floating body 8 , and a supporting cantilever 2 . The water-retaining floating body 7 is set as a cuboid box structure, and the water-retaining floating body 7 is provided with a separate water tank 3, and the water tank 3 is equipped with a submersible pump for irrigation and drainage; at the center of buoyancy to ensure stable floating and prevent overturning; the supporting floating body 9 is also arranged as a cuboid box structure, and the supporting floating body 9 is provided with a separate water tank 3, and the water tank 3 is equipped with a submersible pump for irrigation and drainage; the bottom of the water tank 3 The weight is arranged so that the center of gravity of the supporting floating body 9 is lower than the center of buoyancy to ensure stabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com