Preparation technology of insulation board with sandwich structure

A technology of preparation process and sandwich structure, applied in thermal insulation, building components, etc., can solve problems such as increased thermal conductivity, decreased product quality, and broken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

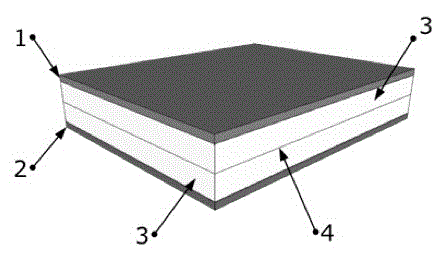

[0021] Such as figure 1 As shown, the present invention is a hydrophobic perlite insulation board with a sandwich structure. There are 5 layers in total, which are multi-layer mesh cloth layer (2), hydrophobic expanded perlite layer (3), and single-layer mesh cloth layer ( 4), hydrophobic expanded perlite layer (3), multi-layer grid cloth layer (1).

[0022] In the above example, the multi-layer mesh cloth layer (1) contains 8 layers of mesh cloth, and the multi-layer mesh cloth layer (2) contains 3 layers of mesh cloth;

[0023] In the above example, the grid cloth is PET grid cloth or PA6 grid cloth or glass fiber grid cloth;

[0024] In the above example, the auxiliary material is PET staple fiber or PA6 staple fiber or glass fiber staple fiber with a length of 10-20mm;

[0025] The density of perlite in the above example is 100~400kg / m 2 , The thickness of hydrophobic expanded perlite layer is 20mm~50mm.

[0026] The implementation process of the present invention is: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com