Test method for measuring limit tip cold bending angle and equivalent fracture strain

A technology for determining limits and test methods, applied in the direction of using stable bending force to test the strength of materials, measuring devices, instruments, etc., can solve the problem of increasing the cost of test equipment, difficult to meet VDA238-100 technical standards, weakening the interpretability of results, etc. problems, to achieve the effect of reducing the cost of testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

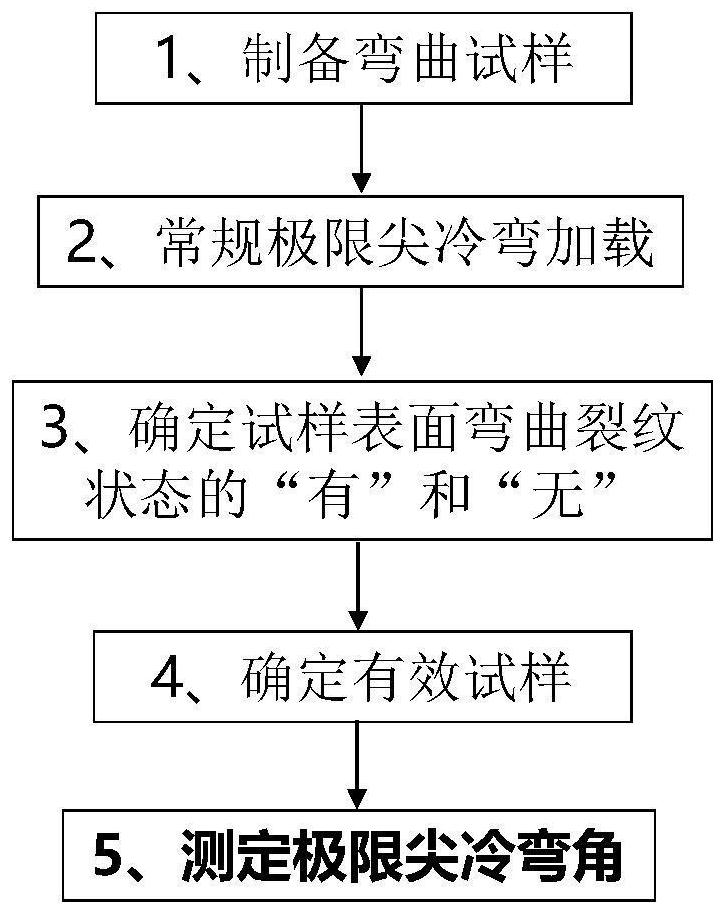

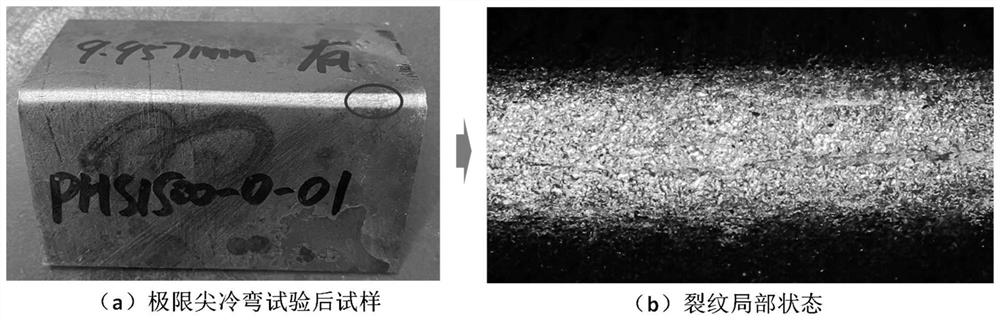

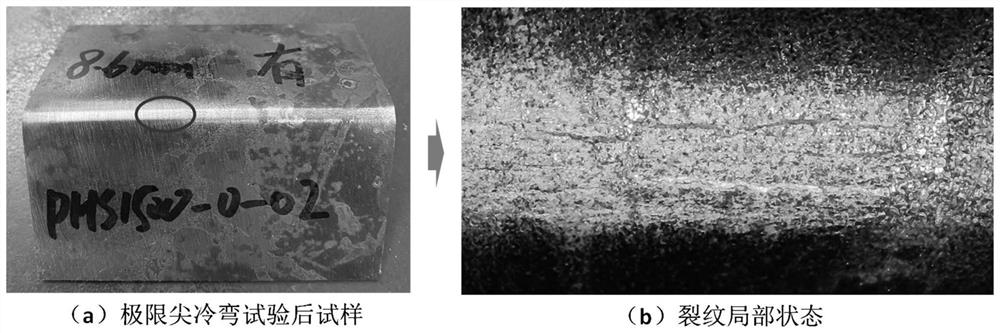

[0069] The present embodiment takes 1500MPa / 1.2mm of hot-formed steel bare plate as an example, using electron microscopy to assist observation to determine the crack state, the flowchart, such as Figure 1 The test flowchart for determining the ultimate sharp cold bend is shown, including the following steps:

[0070] Step 1: Prepare bending specimens: According to the specimen size requirements specified in the VDA238-100 technical standard, prepare a number of bending specimens of the tested materials for the ultimate tip cold bending test, and the test size is 60mm*60mm.

[0071] Step 2: The conventional ultimate tip cold bending test is used to determine the initial fixed loading stroke d 0 The specific method is: take an initial sample from the prepared bending specimen, placed on the test device in accordance with the technical requirements of the VDA238-100 technical standard for extreme tip cold bending test, until the pressure value reaches the closing threshold when th...

Embodiment 2

[0077] The present embodiment takes 1500MPa / 1.2mm of hot-formed steel bare plate as an example, using electron microscopy to assist observation to determine the crack state, the flowchart, such as Figure 6 The test flowchart for determining the equivalent fracture strain shown includes the following steps:

[0078] Step 1: Prepare bending specimens: According to the specimen size requirements specified in the VDA238-100 technical standard, prepare a number of bending specimens of the tested materials for the ultimate tip cold bending test, and the test size is 60mm*60mm.

[0079] Step 2: The conventional ultimate tip cold bending test is used to determine the initial fixed loading stroke d 0The specific method is: take an initial sample from the prepared bending specimen, placed on the test device in accordance with the technical requirements of the VDA238-100 technical standard for extreme tip cold bending test, until the pressure value reaches the closing threshold when the lo...

Embodiment 3

[0095] The present embodiment takes 1500MPa / 1.6mm aluminum-silicon coated hot-formed steel as an example, and gives the determination of the ultimate tip cold bend angle and equivalent fracture strain based on the simulation model, mainly to verify the effectiveness of the theoretical formula.

[0096] The simulation model is used to simulate the test conditions of VDA238-100, the mesh size of this model is 0.15mm, the equivalent fracture strain of the material determined by uniaxial tensile is 0.251, when the equivalent plastic strain reaches 0.251 is the material failure, in this simulation model, as long as one element reaches the equivalent fracture strain, it indicates that the test is terminated, and the specimen deformation state at this time is used to determine the ultimate sharp cold bend angle and the equivalent fracture strain.

[0097] The ultimate tip cold bend angle is directly determined for the simulation model termination state, and the measurement size is 48.2°,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com