Multi-degree-of-freedom hoisting manipulator

A technology of manipulator and degrees of freedom, applied in cranes and other directions, can solve the problems of high noise during the movement of the hoisting mechanism, heavy objects swinging, rotating, and small movement range of the boom, so as to achieve smooth operation, reduce noise, and improve use stability. and the effect of the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

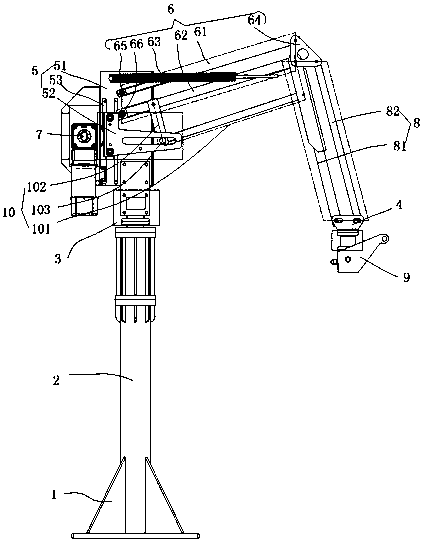

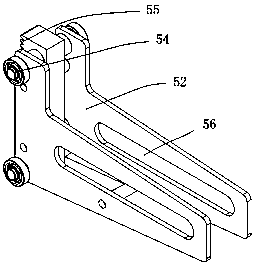

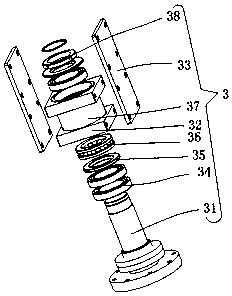

[0019] Figure 1 to Figure 5 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a structural schematic diagram of the moving block in the up and down sliding mechanism of the present invention; image 3 It is an explosion schematic diagram of the first rotating mechanism of the present invention; Figure 4 It is a structural schematic diagram of the second rotating mechanism of the present invention; Figure 5 It is a structural schematic diagram of the machine head of the present invention.

[0020] See Figure 1 to Figure 5 , a multi-degree-of-freedom lifting manipulator, including a base 1, a column 2 arranged on the base 1, and a manipulator structure arranged on the column 2, the manipulator structure includes a first rotation mechanism 3, a second rotation mechanism 4. Up and down sliding mechanism 5, cantilever mechanism 6, reduction motor 7, swing arm mechanism 8 and mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com