Opening-closing valve for LED (Light Emitting Diode) light tube glass granular raw material storage bin

A technology of LED lamps and glass particles, applied in valve details, valve device, valve operation/release device, etc., can solve the problems of raw material leakage, poor sealing, jamming failure, etc., to achieve convenient material use and avoid jamming Phenomenon, effect of low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

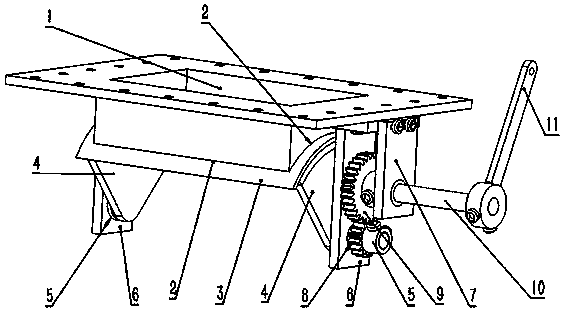

[0009] figure 1 As shown: the arc-shaped opening 2 under the rectangular valve body 1 is equipped with a closed valve 3 corresponding to the opening 2, and the support plates 4 on both sides of the closed valve 3 are movably installed on both sides of the valve body 1 through the rotating shaft 5 Below the support seat A6, a support seat B7 is provided at intervals outside the support seat A6 on one side of the valve body. The driven gear 8 mounted on the rotating shaft 5 is in transmission engagement with the drive gear 9 at the inner end of the drive shaft 10 between the two. A handle 11 is provided at the outer end of the shaft 10 passing through the support seat B7.

[0010] In this technical solution: when the handle 11 is installed and used, it can be switched manually, or connected with a pneumatic device to realize the switch through pneumatic rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com