Thickness measuring probe

A technology of thickness measurement and probe emission, which is applied to measuring devices, instruments, and the use of ultrasonic/sonic/infrasonic waves, etc., can solve problems such as the impact of detection effects, achieve good sound insulation, thin thickness, and improve detection effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

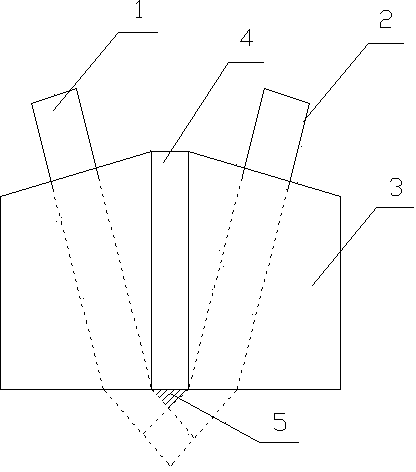

[0013] like figure 1 As shown, a thickness measuring probe includes a transmitting probe 1, a receiving probe 2 and two identical wedges 3, the two wedges 3 are separated by a sound insulation layer 4, and the two wedges 3 are opposite Mirroring the sound insulation layer 4, the top of each wedge 3 is an inclined surface, and the higher end of the inclined surface is close to the sound insulation layer 4, and the lower end of the inclined surface is far away from the sound insulation layer 4; the sound insulation layer 4 Vertical to the horizontal plane, the two inclined surfaces are symmetrical about the sound insulation layer 4, the transmitting probe 1 and the receiving probe 2 are arranged symmetrically on the inclined surface of the wedge 3 respectively, and the sound insulation layer 4 is polypropylene with a thickness of 0.4-0.5 mm.

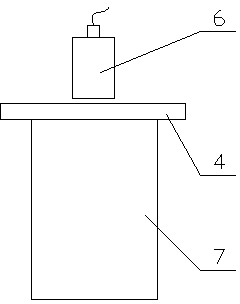

[0014] Take the 0.5mm cork board as a comparative example to carry out a comparative test, such as figure 2 As shown, the sound insula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com