Quick-vacuum-pumping negative-pressure dry type leakage detecting device

A technology for pumping negative pressure and equipment, which is applied in the field of leak detection equipment, can solve the problems of not fully meeting customer working conditions, low efficiency, and long detection time, so as to shorten preparation hours, save time, and shorten negative pressure leak detection the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

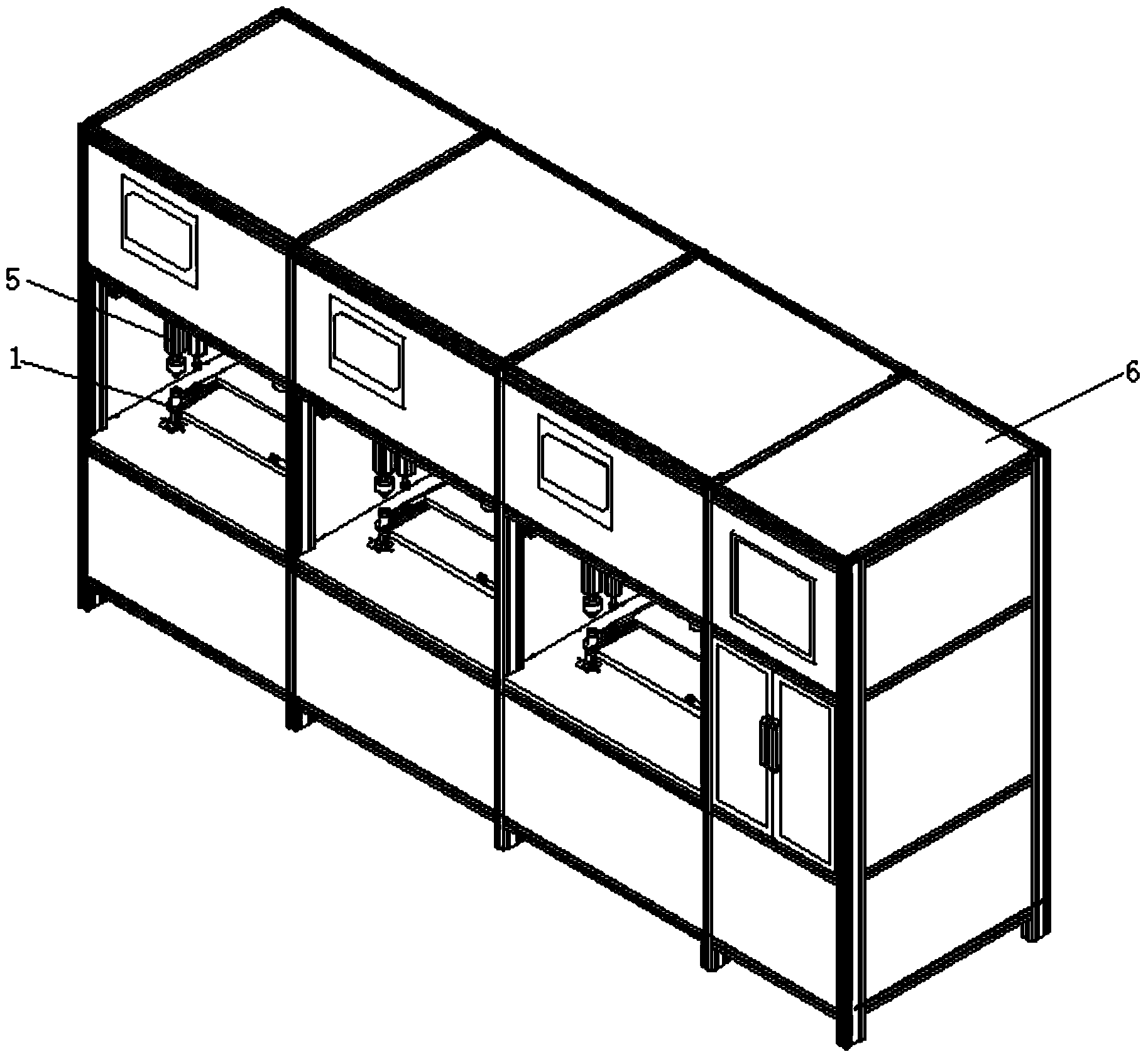

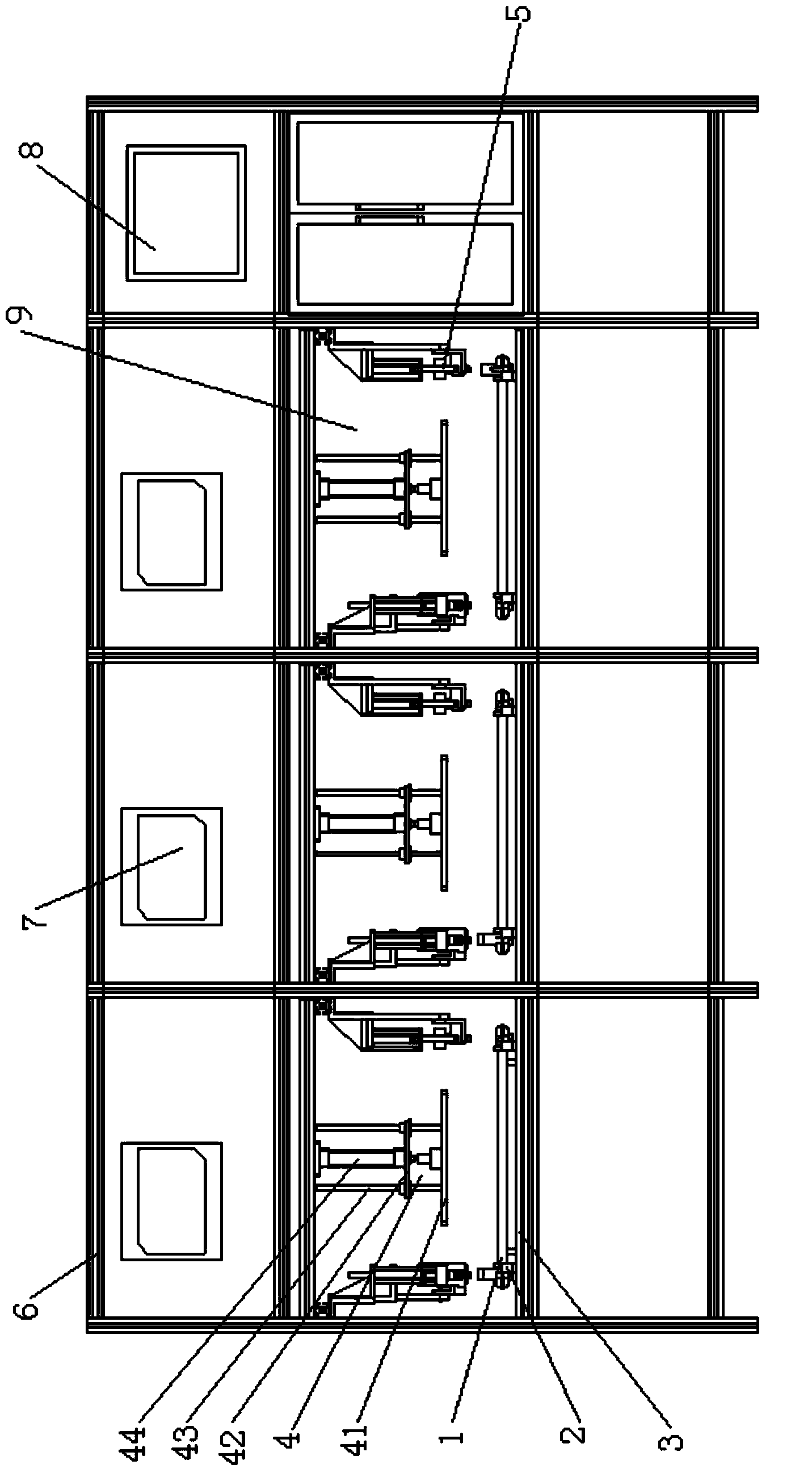

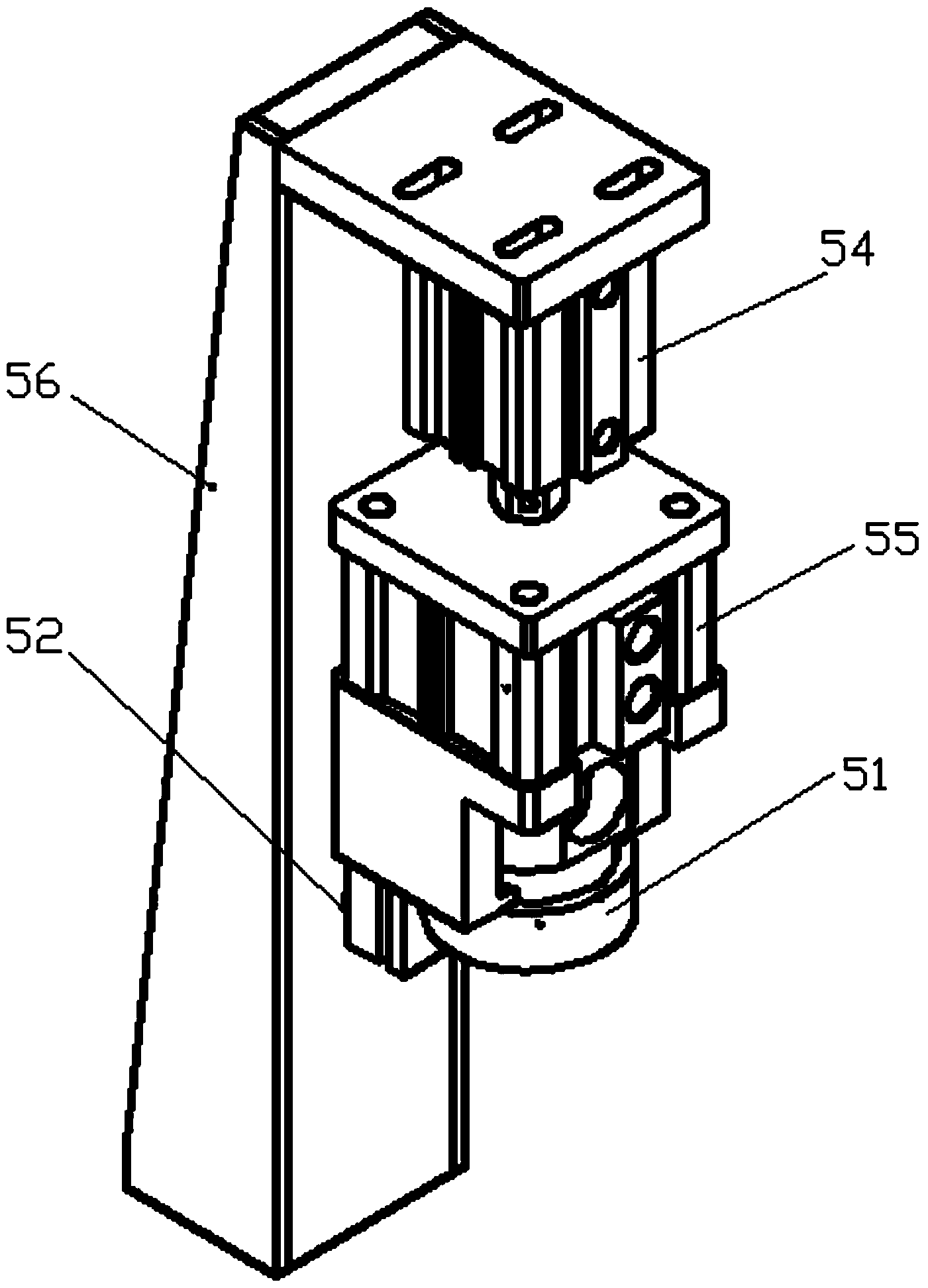

[0025] like Figure 1 to Figure 4 As shown, this embodiment proposes a quick-pump negative pressure dry leak detection device, including a device body 6, a clamp assembly 4 for fixing the workpiece, a plugging assembly 5 for sealing the air hole of the workpiece, and a The touch screen 8 for selecting the workpiece model and the leak detector 7 for testing the airtight performance of the workpiece 1. The clamp assembly 4, the blocking assembly 5, the touch screen 8 and the leak detector 7 are arranged in the device body.

[0026] The equipment body includes a base plate 3 and a plurality of cavities 9 , and a positioning block 2 is arranged on the base plate 3 , and the workpiece 1 is arranged at a predetermined position on the base plate 3 through the positioning block 2 .

[0027] The leak detector 7 is arranged above the cavity, corresponding to the cavity in the device body, and different types of products are placed in different cavities. One end of the leak detector 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com