tofd test block multi-channel sequential automatic scanning mechanism

A multi-channel, test block technology, applied in the field of ultrasonic testing, can solve problems such as heavy workload, incomplete data, and affecting scanning results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

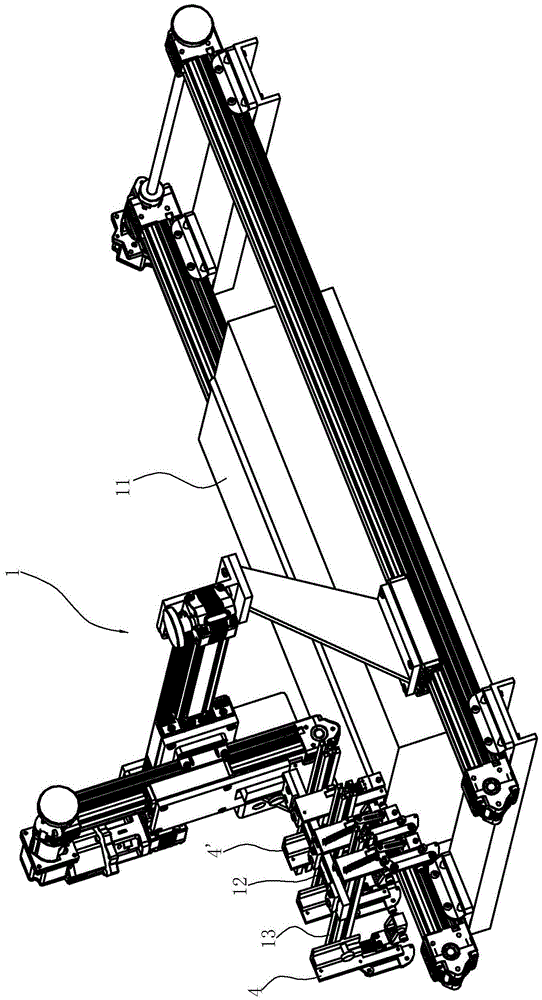

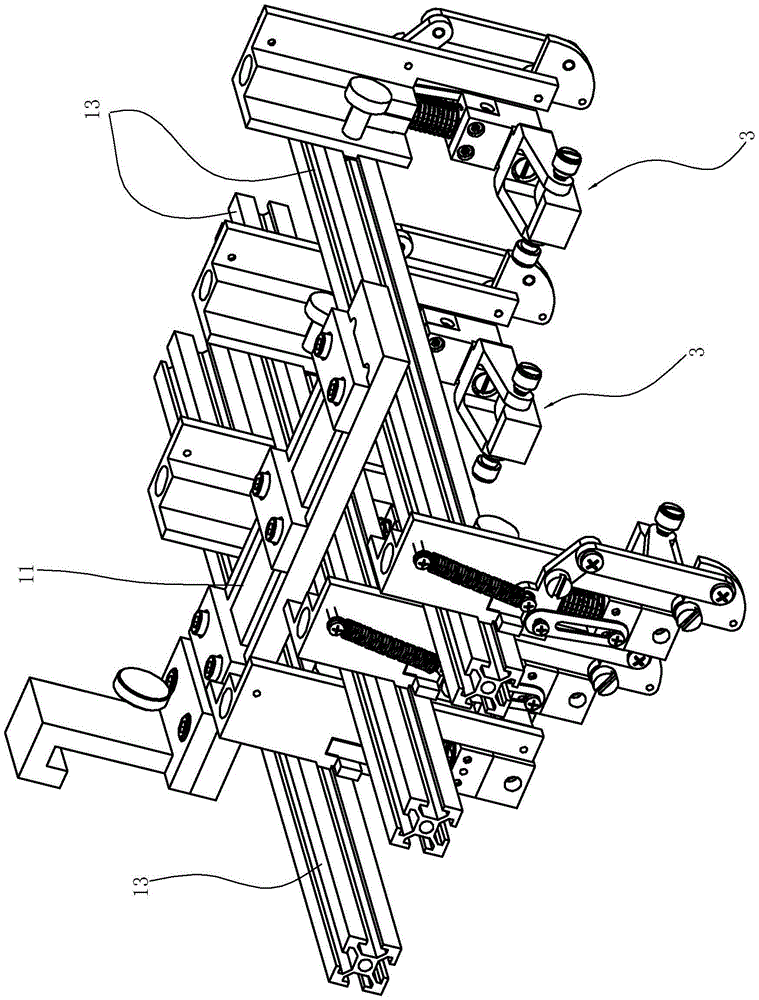

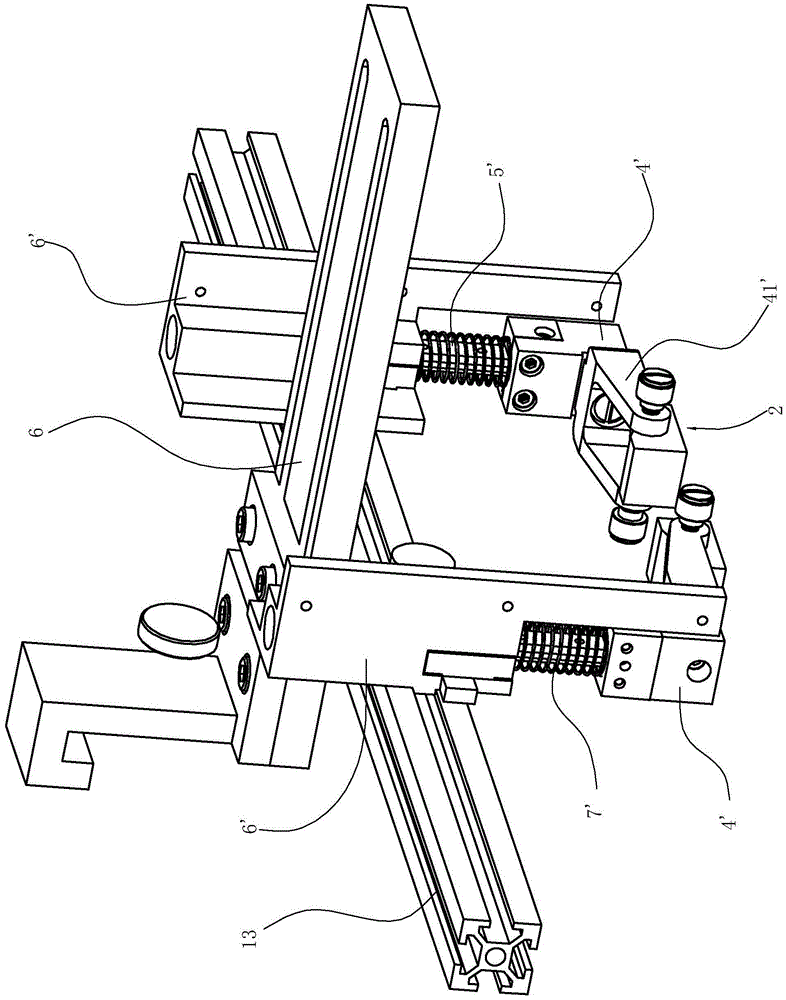

[0022] Such as Figure 1 to Figure 7 As shown, the TOFD test block automatic scanning device includes:

[0023] The scanning frame 1 is sleeved on the outside of the test block 11, and the scanning frame can be selected from any one of the prior art as required, such as an automatic scanning frame or a manual scanning frame. This embodiment is an automatic scanning frame, which is driven by a three-dimensional linear motion module, and the output end of the three-dimensional linear motion module is connected to the probe group through the base 12 . In order to facilitate the adjustment of the relative position between the two probes in each probe group, the present embodiment is respectively provided with slide seats 13 corresponding to each probe group on the base 12, and each probe group is connected to the slide seat through its own connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com