Method of detecting trichloromethane and carbon tetrachloride in chlorinated polypropylene and method for measuring contents of trichloromethane and carbon tetrachloride in chlorinated polypropylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

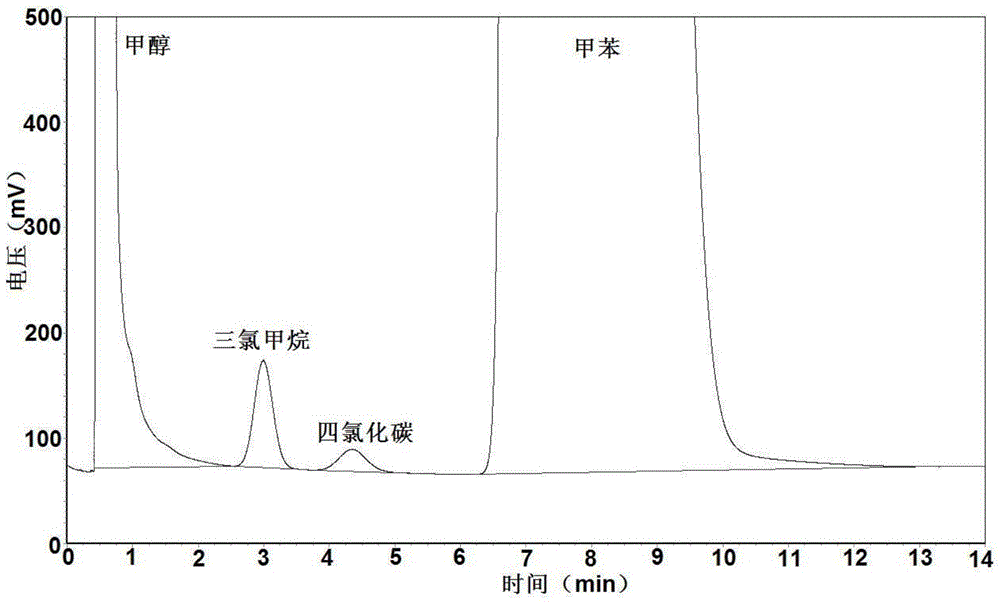

Image

Examples

Embodiment 1

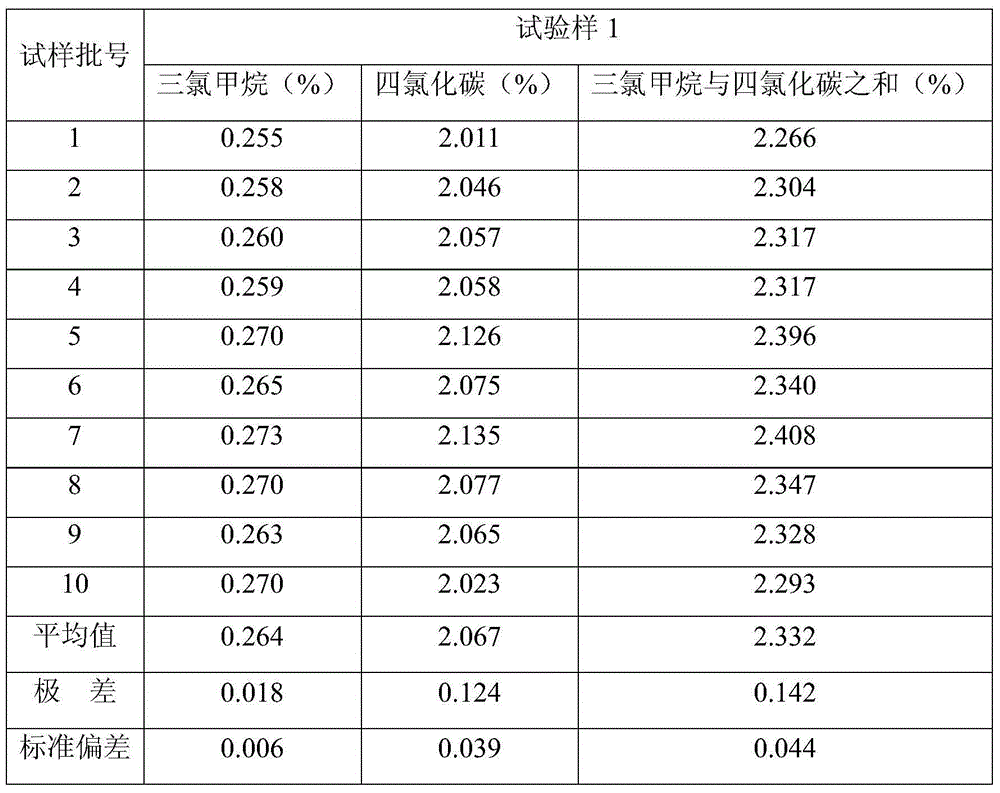

[0057] Embodiment 1 measures a certain test sample according to the method described above, and its measurement results are shown in table 2 below

[0058] Table 2 Analytical test results

[0059]

[0060] In summary, the detection method of the present invention can quickly and accurately detect whether chloroform, carbon tetrachloride and their content remain in chlorinated polypropylene, thereby guiding the adjustment of process parameters and providing accurate data for product quality monitoring .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com