Junction device of circuit breaker, circuit breaker and circuit breaker assembly

A technology for wiring devices and circuit breakers, applied in the direction of protective switch terminals/connections, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

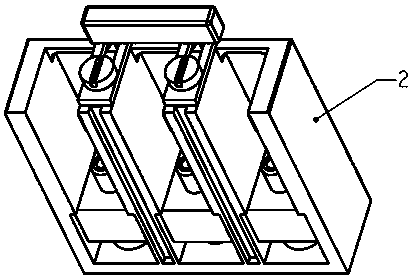

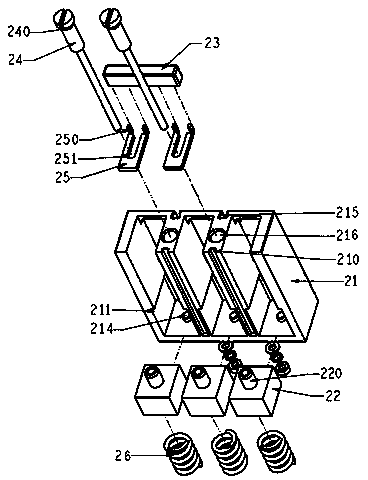

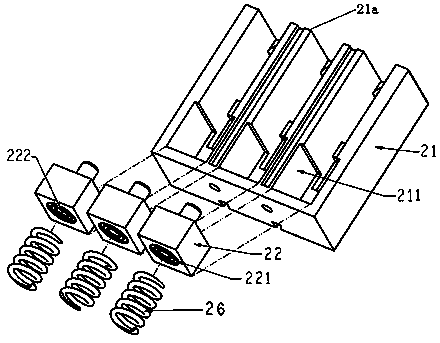

[0045] like Figure 1-2 As shown, the wiring device 2 of the molded case circuit breaker of this embodiment includes a terminal block 21 for realizing the electrical connection between the circuit breaker body and the cable. It includes a notch 212 at the top and a slot 211 communicating with the notch 212, and the outer wall of the terminal block 21 facing the insertion direction of the cable terminal 3 is provided with a card slot 215, and the card slot 215 is provided with For the arc shield, an elastic piece is arranged in the installation groove, and the elastic piece is installed in the installation groove through a fixing assembly, and the elastic piece has a mounting part. In this embodiment, the mounting part It is a boss 220, and the installation part can be respectively connected with the circuit breaker body 1 and the cable terminal 3 inserted into the installation groove, and a ridge 21a is formed between adjacent installation grooves, and a circuit breaker is arr...

Embodiment 2

[0054] like Figure 7 As shown, this embodiment provides a circuit breaker that can be used in conjunction with the wiring device described in Embodiment 1, including a circuit breaker body 1, and several protruding terminal blocks 10 are arranged on the circuit breaker body 1. The wiring board 10 is suitable for being inserted into the installation groove of the wiring device 2 in Embodiment 1. The wiring board 10 is provided with a wiring part 11, and the wiring part 11 is inserted into the installation groove after the wiring board 10 is inserted into the installation groove. It is suitable for socketing or inserting cooperation with any of the installation parts described above to fix the cable terminal inserted into the installation groove.

[0055] In this embodiment, the cover of the circuit breaker body 1 is provided with a snap-in groove 13 for sliding insertion of the sliding part 25, and the setting of the snap-in slot 13 facilitates the installation and connection ...

Embodiment 3

[0058] like Figure 7-9 As shown, the circuit breaker assembly of this embodiment includes a circuit breaker, a cable, and a wiring device 2 for realizing the electrical connection between the circuit breaker and the cable, and the wiring device 2 is the wiring device described in Embodiment 1 2. The circuit breaker is the circuit breaker described in Embodiment 2.

[0059] In this embodiment, the terminal board 10 is arranged opposite to the two sides of the circuit breaker body. The ridge 21a is provided with a groove 210 on the side wall facing the circuit breaker body, and the rib 12 on the outer wall of the circuit breaker is fitted into the groove 210, and the rib 12 is fitted into the groove 210. The cooperating arrangement of the rib 12 and the groove 210 makes the installation between the circuit breaker and the terminal block 21 more firm, avoids relative positional movement when the external shock occurs, and further improves the stability of the mechanism, and ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com