Peeling device

A peeling device, cement curing technology, applied in construction, building maintenance, manufacturing tools, etc., can solve problems such as poor work efficiency, loud beating noise, and damage to mortar.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

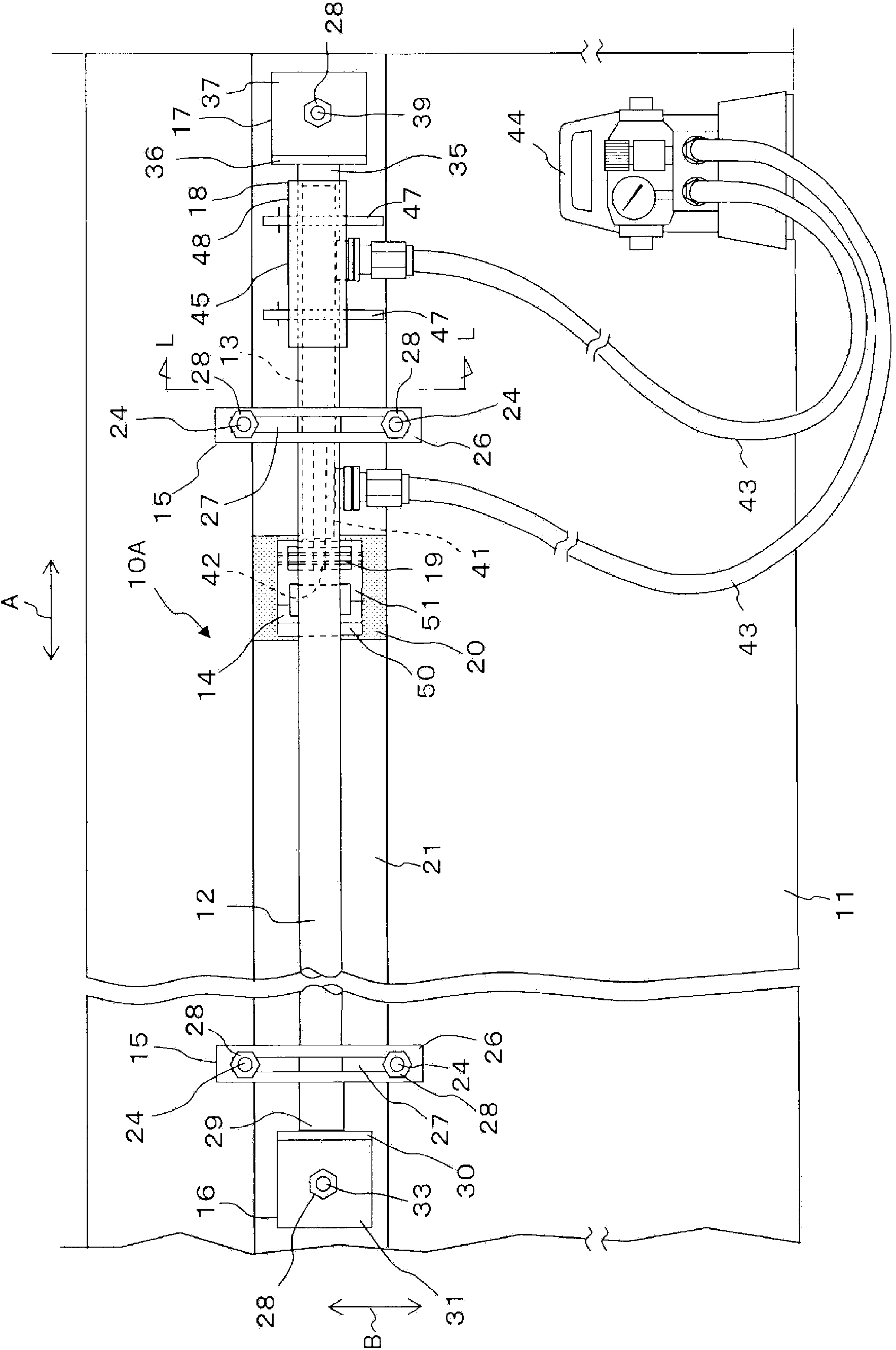

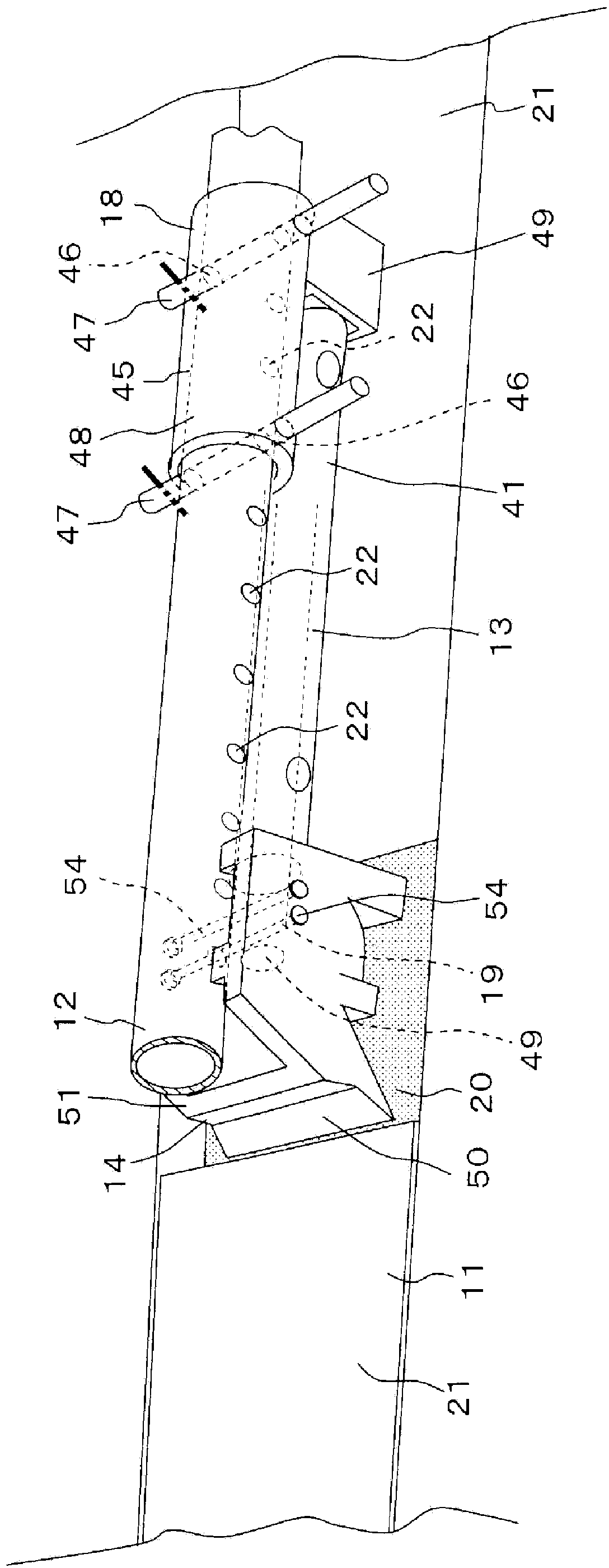

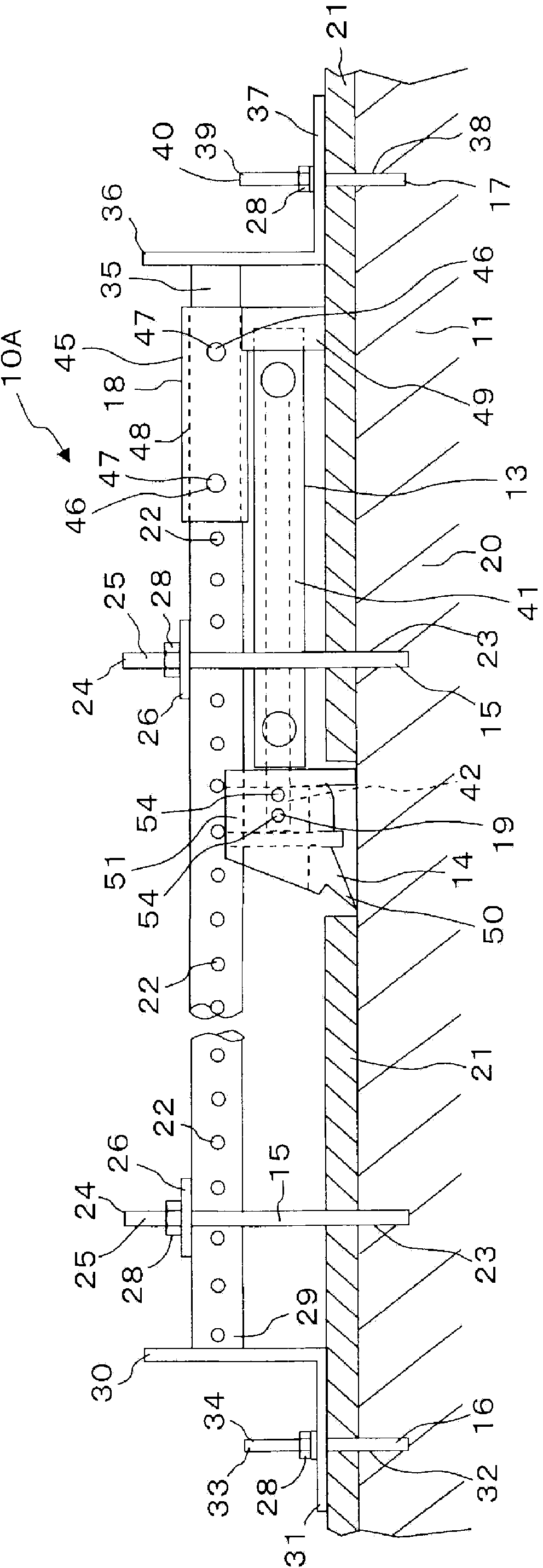

[0058] Referring to the top view of the peeling device 10A shown as an example, that is figure 1 The details of the peeling device according to the present invention will be described as follows with reference to the accompanying drawings. in addition, figure 2 is a perspective view of the peeling device 10A, image 3 is a side view of the peeling device 10A, Figure 4 yes figure 1 L-L line to see the sectional view, Figure 5 It is an enlarged perspective view of the cutter 14. FIG.

[0059] figure 1 In , the single direction is represented by arrow A ( figure 1 In the shown building, it is the front and rear direction), and the arrow B indicates the width direction intersecting with the single direction ( figure 1 The building shown is up and down). Figure 1 ~ Figure 4 In , the peeling apparatus 10A is shown in the state installed in the upper part of the inner wall 11 of a building. figure 2 In , the illustration of the front and rear ends 29, 35 of the guide me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com