Winding-tying type Chinese sausage tying and pricking machine

A sausage and wire tying technology, which is applied in the field of wrapping sausage tying and hole-piercing machines, can solve the problems of complexity, large labor force, and high noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

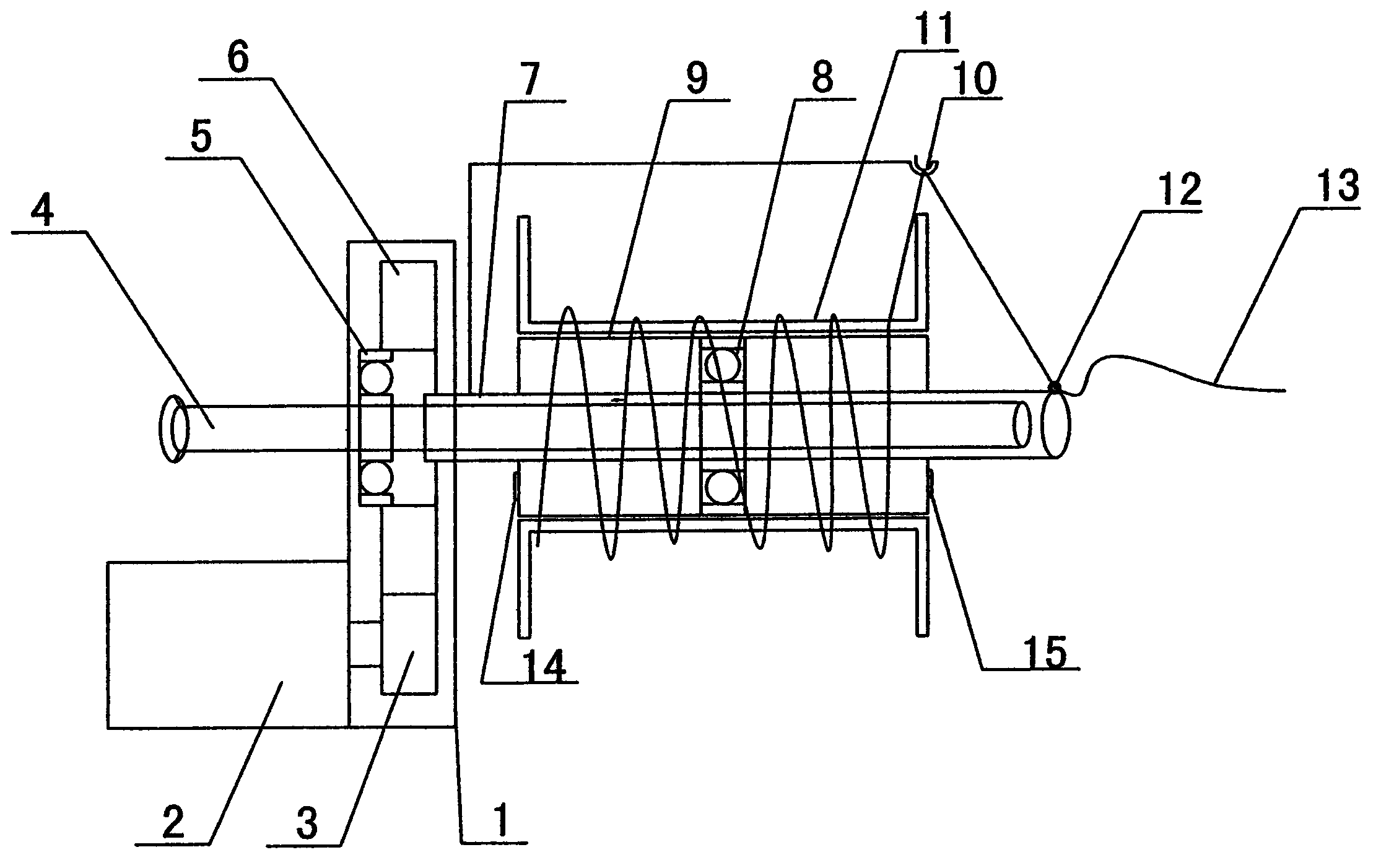

[0012] The present invention will be further described below through specific implementation methods and in conjunction with the accompanying drawings.

[0013] The structure of the winding-type sausage-tying wire-punching machine of the present invention is as shown in Figure 1, in which there is a housing 1, a motor 2, a small gear 3, a sausage passage tube 4, a bearing 5, a large gear 6, and a shaft sleeve 7 , bearing 8, wire spool 9, wire hook 10, wire spool 11, threading hole 12, line 13, spring 14, adjust friction skin 15.

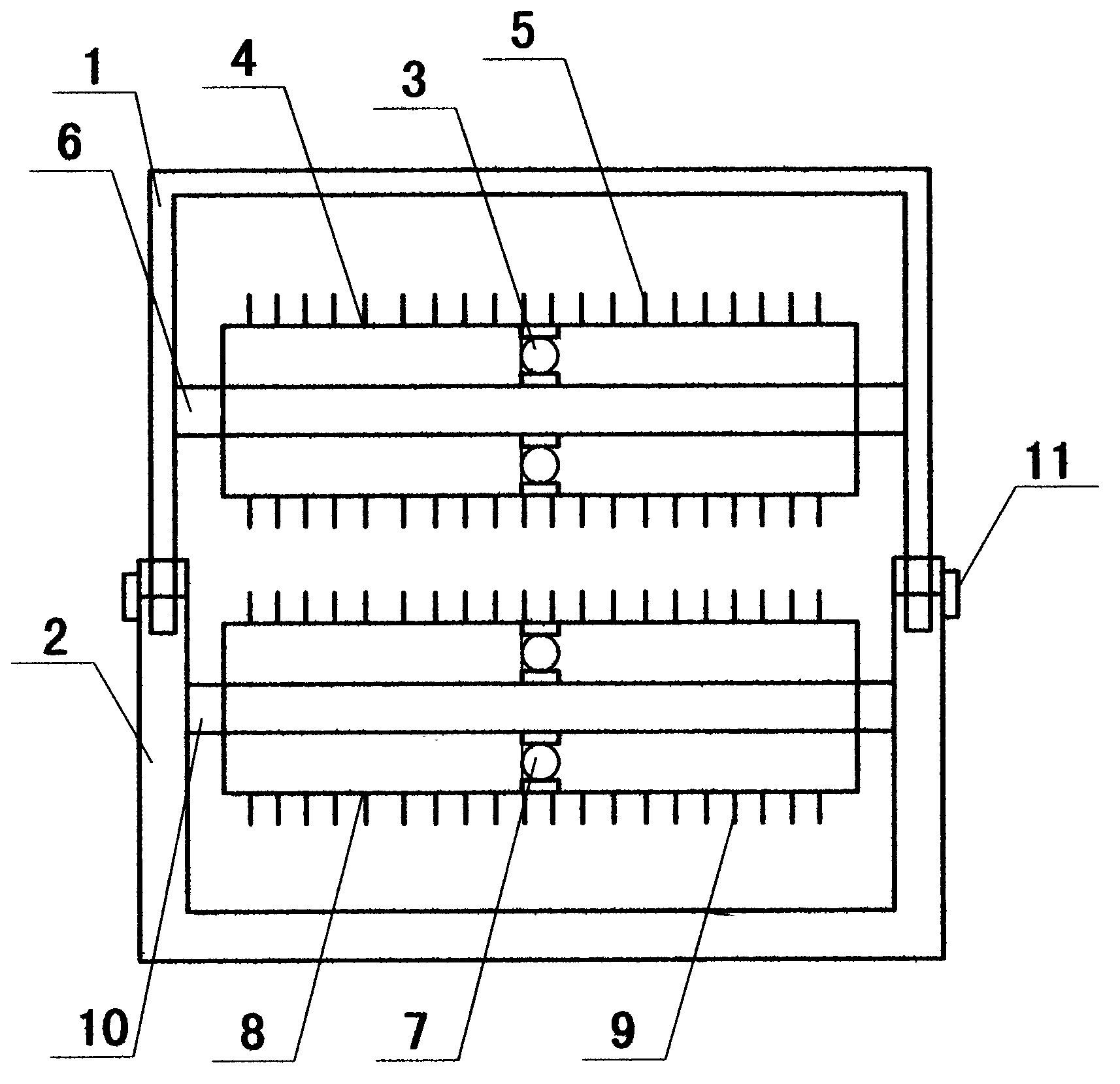

[0014] figure 2 : Upper bracket 1, upper bearing 3, upper needle tube 4, upper steel needle 5, upper shaft 6, lower bearing 7, lower needle tube 8, lower steel needle 9, lower shaft 10, lower bracket 2, adjustment screw 11.

[0015] Wrapping type sausage tying wire and hole machine, the small gear 3 is fixed on the motor 2 shaft, the bearing 5 is fixed on the sausage passage tube 4, the large gear 6 is fixed on the bearing 5, the bearing 8 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com