Arc-control device for high-voltage capacitor separation

A technology of arc extinguishing device and capacitor, which is applied in the direction of circuit, sorting, electric switch, etc. It can solve the problems of capacitor lead wire damage and affect the appearance of the product, and achieve the effect of improving the appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

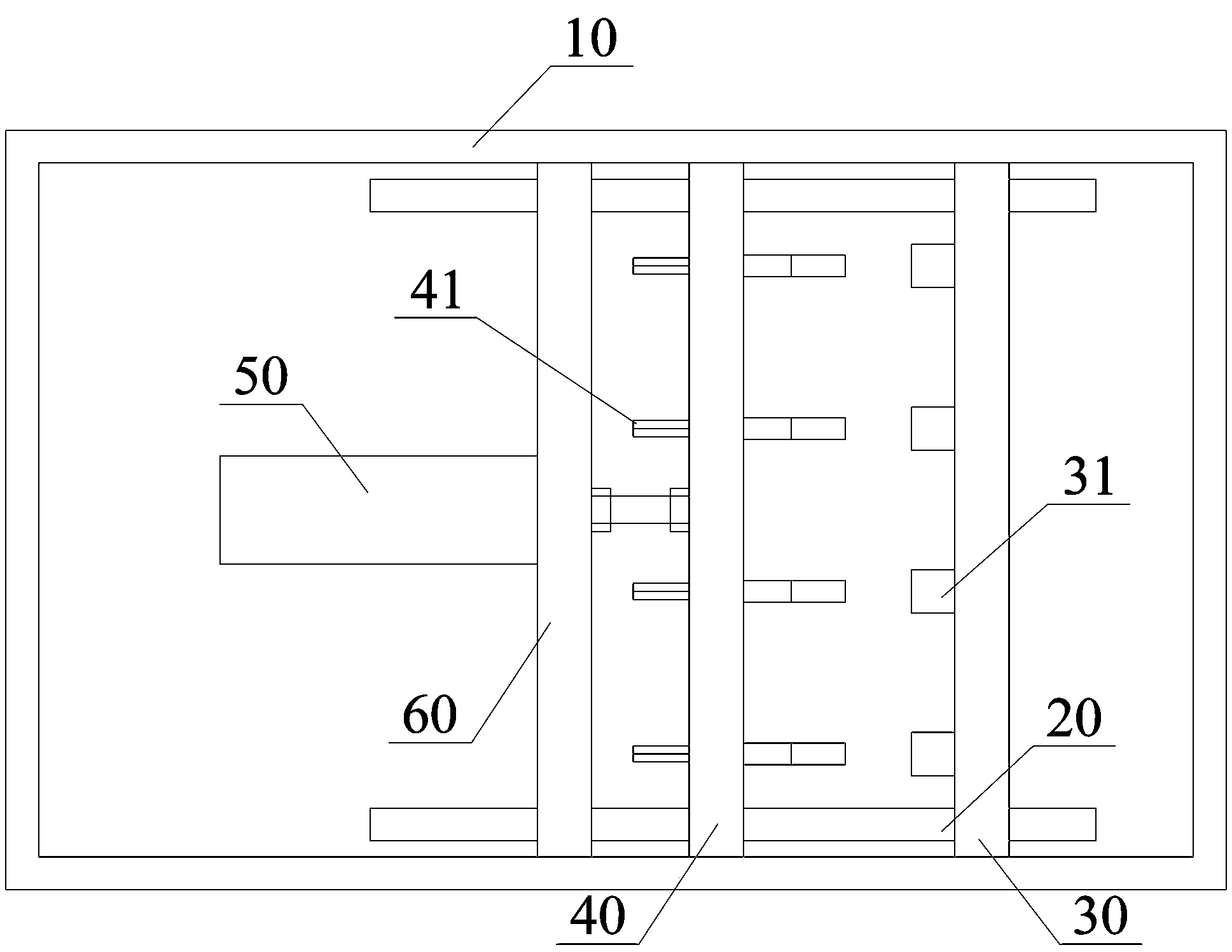

[0011] According to the accompanying drawings, the present invention is an arc extinguishing device for high-voltage sorting of capacitors, which includes a high-voltage measurement box 10 installed in the high-voltage sorting machine for capacitors.

[0012] The box body 10 is provided with two parallel fixed shafts 20 for positioning. The fixed shafts are provided with a static insulator 30 and a movable insulator 40. The movable insulator 40 is connected with a cylinder 50 that drives it to move along the fixed shaft. The movable insulator 40 It can move along the fixed axis toward the static insulator 30 , and the movable insulator is provided with a probe 41 and a linear bearing (not shown in the figure), and the static insulator 30 is provided with a copper column 31 corresponding to the probe 41 .

[0013] The probe 41 and the linear bearing are embedded on the moving insulator 40 ; the surface of the static insulator is provided with screw holes, and the copper pillar 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com