Preparation method of V150 steel grade OCTG full-scale physical test sample

A physical test and sample preparation technology, applied to tubular objects, manufacturing tools, welding equipment, etc., can solve problems such as poor weldability, unsatisfactory welded joint strength, toughness and fatigue strength, and brittle welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

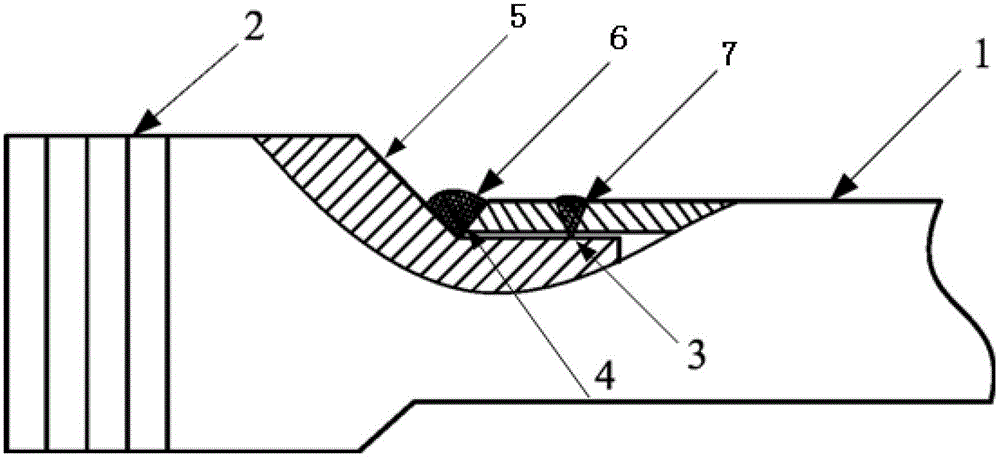

[0025] see figure 1 , the embodiment of the present invention provides a method for preparing a full-scale physical test sample of a V150 steel grade oil well pipe, and the method is operated according to the following steps:

[0026] Step 1 Welding preparation: take the oil well pipe 1, process the oil well pipe welding groove 4 at both ends of the oil well pipe 1, and process the plug welding hole 3 near the end face of the oil well pipe welding groove 4; take two auxiliary rods 2. Process each auxiliary rod 2 of the two auxiliary rods 2 with a welding groove 5 at one end, and process a thread at the other end of each auxiliary rod 2, and the thread can be processed into an internal thread or an external thread; The two pieces of auxiliary rods 2 are respectively inserted into the two ends of the oil well pipe 1, and the threaded ends of the two auxiliary rods 2 face outward to form a full-scale physical test sample of the oil well pipe.

[0027] Step 2 Preheating of weldme...

Embodiment 2

[0039] see figure 1 , the embodiment of the present invention provides a method for preparing a full-scale physical test sample of a V150 steel grade oil well pipe. The specific implementation process of the method is the same as that of Example 1, except that:

[0040] The oil well pipe 1 specification is: Φ244.48mm×15.11mmV150 steel grade oil well pipe, the chemical composition and its mass percentage are: C: 0.40%, Si: 0.18%, Mn: 0.50%, P: 0.014%, S: 0.0065%, Cr: 1.05%, Mo: 0.25%, Ni: 0.043%, and the balance is Fe.

[0041] The angle between the welding groove 5 of the auxiliary rod and the welding groove 4 of the oil well pipe is 38°. Three plug welding holes are processed at a distance of 105 mm from the end face of the welding groove 4 of the oil well pipe. The plug welding holes 3 are evenly distributed along the circumference of the pipe, and the processing groove angle of the plug welding holes 3 is 38°. Before welding, preheat the full-scale physical test sample of...

Embodiment 3

[0049] see figure 1 , the embodiment of the present invention provides a method for preparing a full-scale physical test sample of a V150 steel grade oil well pipe. The specific implementation process of the method is the same as that of Example 1, except that:

[0050] The oil well pipe 1 specification is: Φ177.80mm×12.65mmV150 steel grade oil well pipe, the chemical composition and its mass percentage are: C: 0.25%, Si: 0.23%, Mn: 0.55%, P: 0.0046%, S: 0.0016%, Cr: 1.02%, Mo: 0.78%, Ni: 0.046%, Cu: 0.051%, and the balance is Fe.

[0051] The angle between the welding groove 5 of the auxiliary rod and the welding groove 4 of the oil well pipe is 37°. Process 3 plug welding holes at a distance of 90 mm from the end face of the welding groove 4 of the oil well pipe. The plug welding holes are evenly distributed along the circumference of the pipe. The plug welding holes 3 are processed with a groove at a certain angle, and the groove angle is 37°.

[0052] Preheat the full-sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com