Gear drilling tool

A drilling tool and gear technology, applied in positioning devices, clamping devices, manufacturing tools, etc., can solve the problems of wrong number of teeth, scrapped gears, low drilling efficiency, etc., to improve efficiency, improve concentricity, and improve drilling efficiency. The effect of hole efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

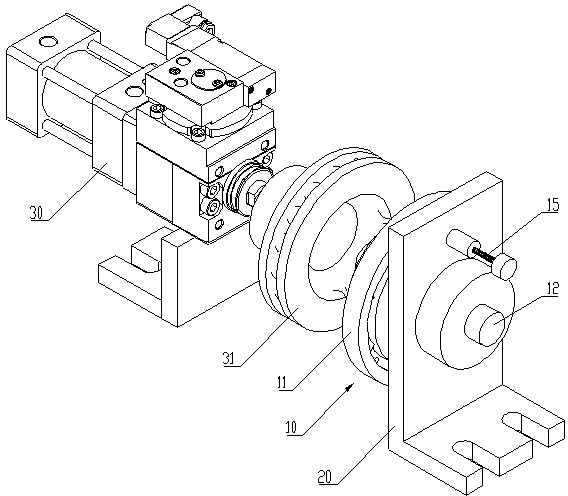

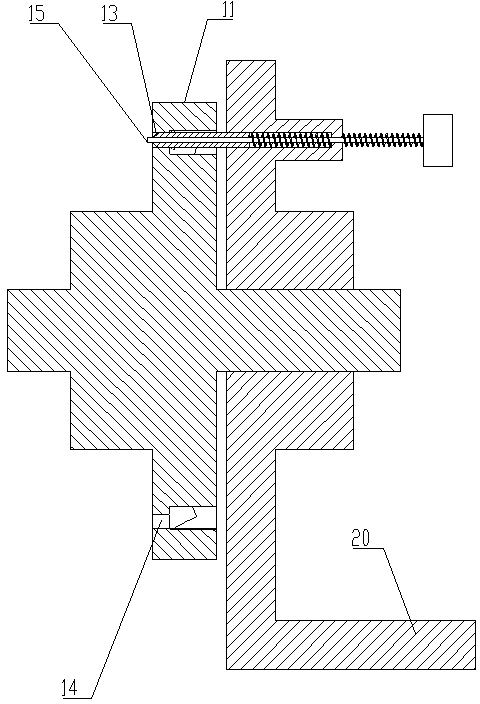

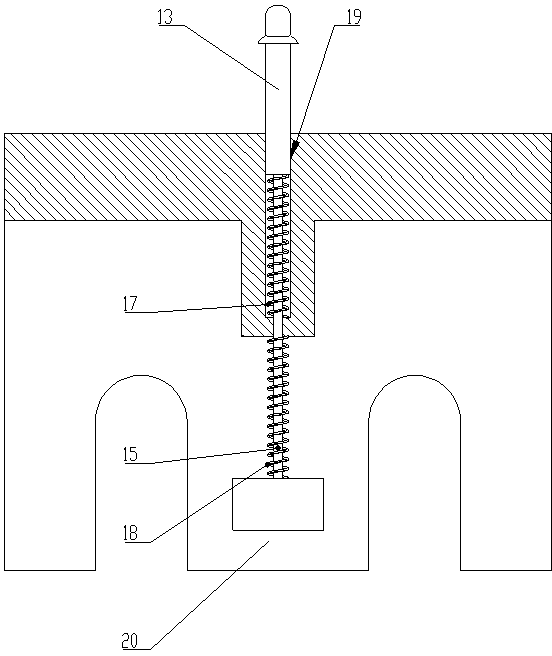

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings, such as Figures 1 to 4 shown:

[0022] The gear drilling tool of the present embodiment includes an angle positioning mechanism 10 capable of automatically adjusting the gear angle so that the oil holes in the gear circumferential direction are evenly distributed, and a base 20 for installing the angle positioning mechanism. The angle positioning mechanism 10 includes a A positioning turntable 11 for fixing the gear, a positioning shaft 12 coaxially arranged on the positioning turntable, and a positioning thimble 13 arranged on the base for fixing the position of the positioning turntable. One end of the positioning shaft 12 is inserted into the base 20 , and rotates and cooperates with the base 20 , the positioning turntable 11 is evenly provided with a plurality of through holes 14 arranged along the axis of the positioning turntable in the circumferential direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com